Monomolecular film preparation instrument

A monomolecular film and controller technology, which is applied in the coating process and coating of metal materials, can solve the problems of uneven heating of the water tank, low success rate of film formation, small film formation area, etc., and achieve the concentration of film formation materials Adjustable, controllable film forming area, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with reference to the drawings and examples, but the present invention is not limited to the following embodiments.

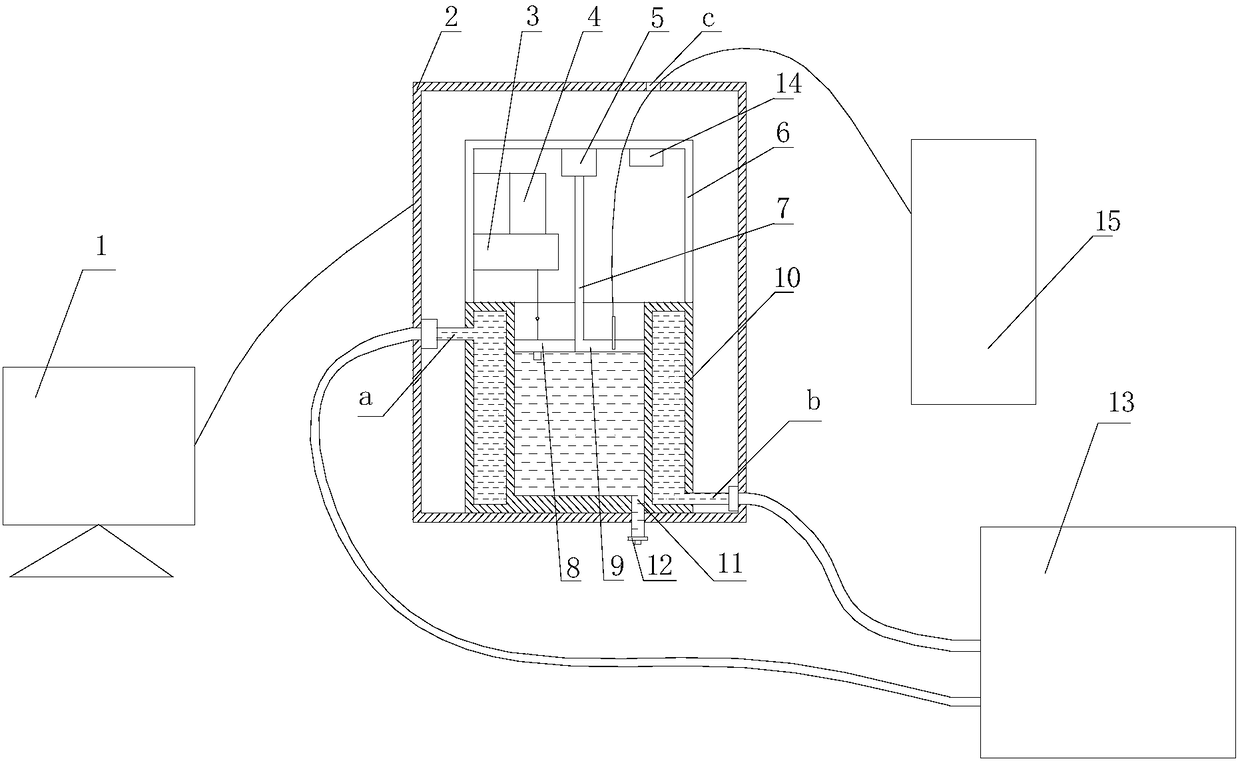

[0016] exist figure 1 Among them, the monomolecular film preparation instrument of this embodiment consists of a computer 1, a dust-free box 2, an interfacial tension detector 3, a coating device 4, a motor 5, a mounting frame 6, a rotating shaft 7, a static sliding barrier 8, a dynamic sliding barrier 9, A constant temperature water tank 10, a liquid discharge pipe 11, a liquid stop clip 12, a constant temperature water bath 13, a controller 14, and a sampling device 15 are connected to form.

[0017] The dust-free box 2 is a transparent rectangular box with a door hinged on the front side. A constant temperature water tank 10 is placed at the bottom of the clean box 2. The dust-free box 2 is used to reduce the evaporation rate of the subphase in the constant temperature water tank 10. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com