A method and device for collecting a section of a sediment layer during a mud deposition test

A test process and deposition layer technology, applied in measuring devices, sampling devices, instruments, etc., can solve the problem of inability to accurately carry out cross-sections at different positions, and achieve the effects of equipment safety, accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

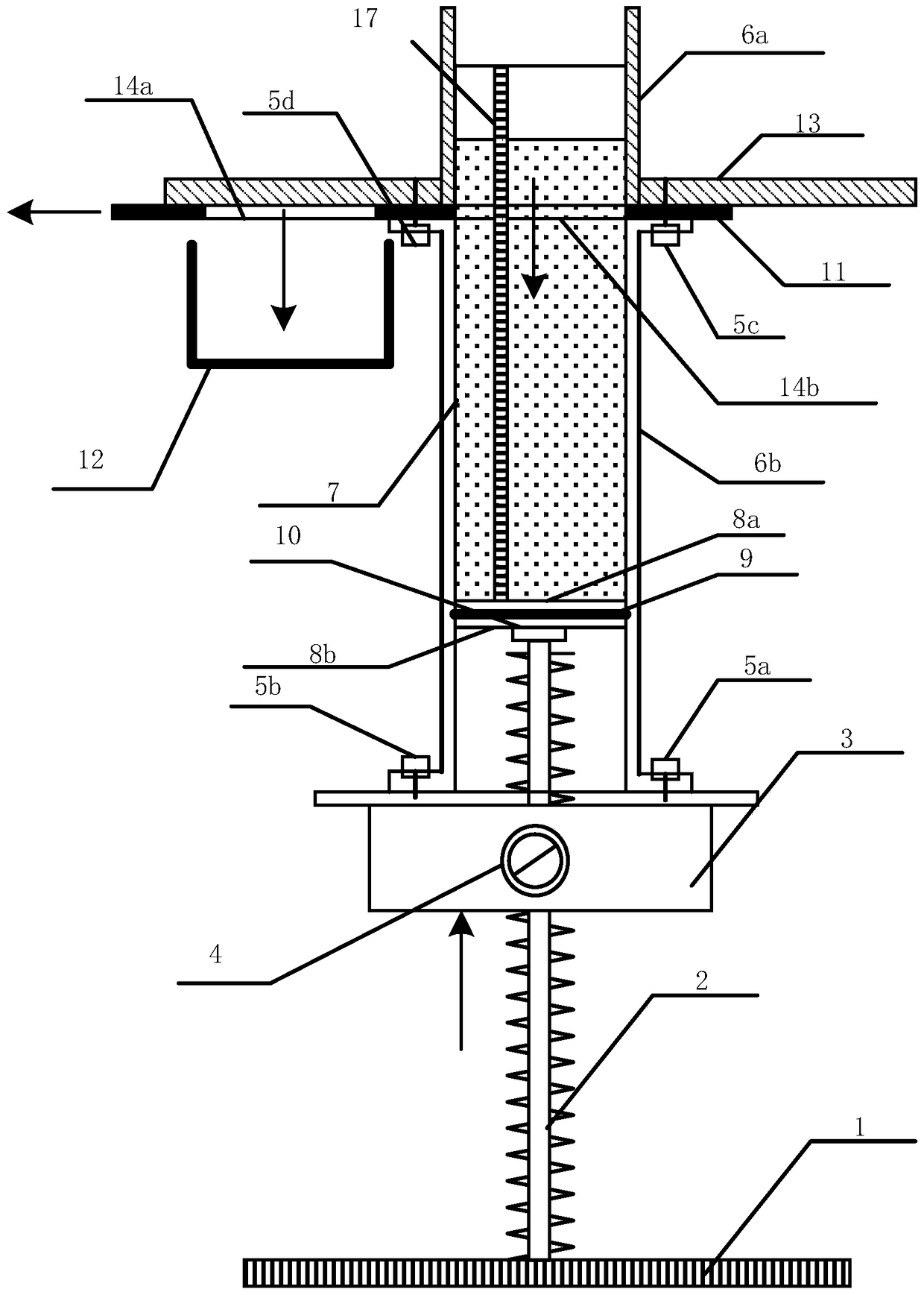

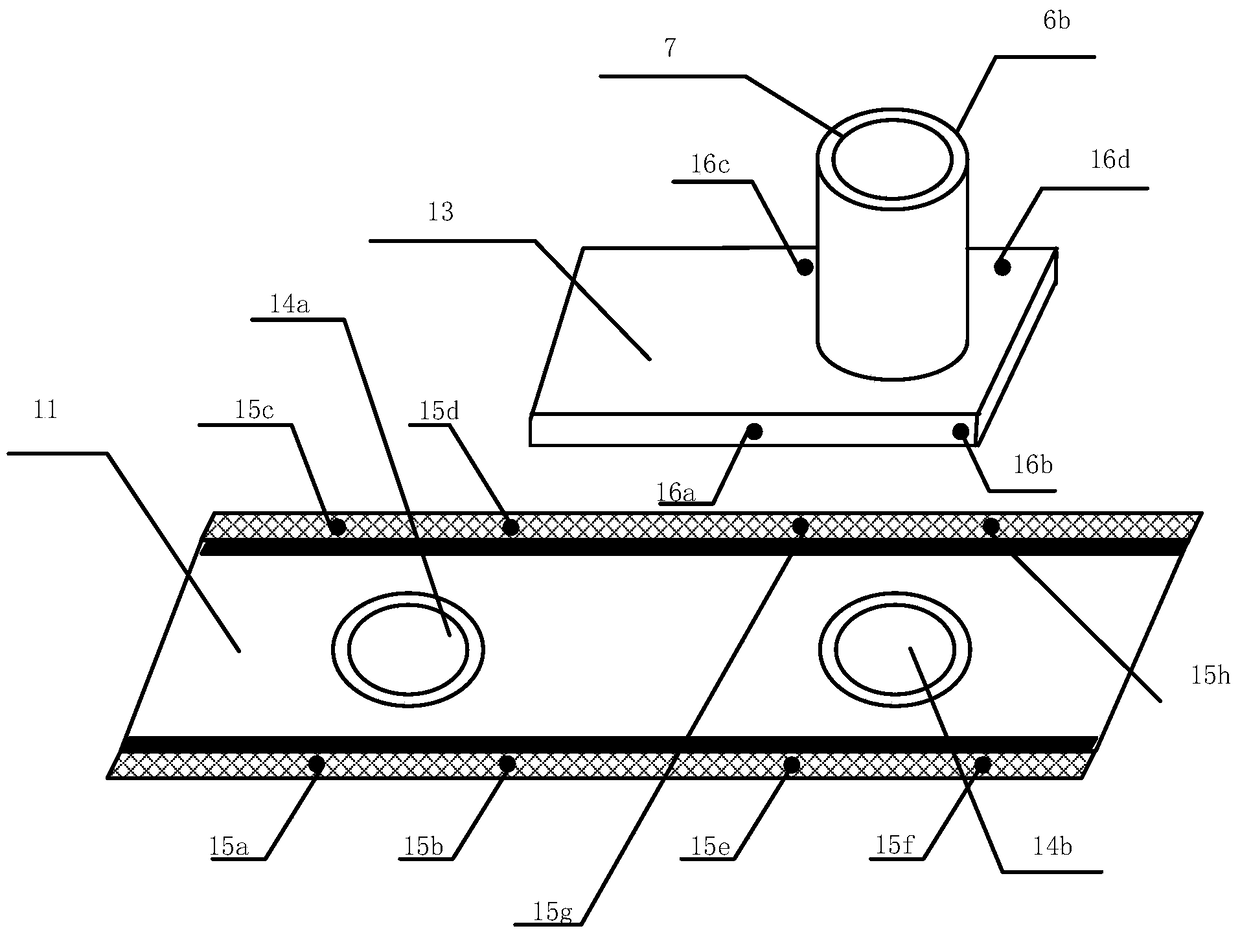

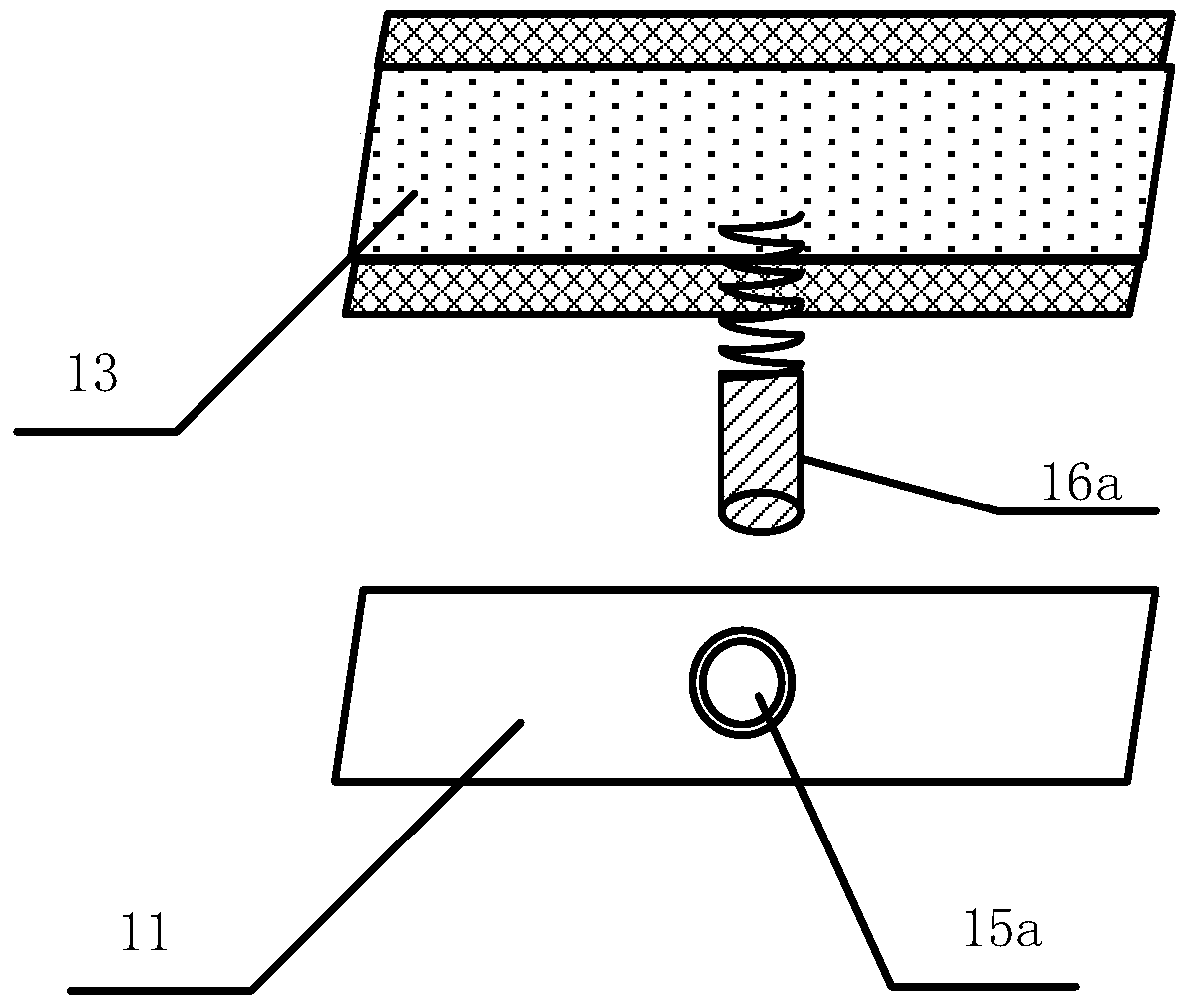

[0049] A device for collecting sediment section sections during a mud deposition test (see Figure 1-Figure 4 ), including a base 1, a spiral lifting rod 2, a transmission gearbox 3, a control valve 4, a first bolt 5a, a second bolt 5b, a third bolt 5c, a fourth bolt 5d, a first outer cylinder 6a, a second outer cylinder 6b, deposition cylinder 7, first upper stopper 8a, second upper stopper 8b, sealing ring 9, steel sheet 10, cutting plate 11, sampling cylinder 12, steel plate 13, first sampling tank 14a, second sampling tank 14b, the first round hole 15a, the second round hole 15b, the third round hole 15c, the fourth round hole 15d, the fifth round hole 15e, the sixth round hole 15f, the seventh round hole 15g, the eighth round hole 15h, The first spring telescopic cap 16a, the second spring telescopic cap 16b, the 3rd spring telescopic cap 16c, the 4th spring telescopic cap 16d and the scale 17, the base 1 is fixed at the bottom of the spiral lifting rod 2, and the speed c...

Embodiment 2

[0069] Since the moving speed of the cutting plate 11 has a great influence on the physical property index of the sample of the collected sediment layer, embodiment 2 adopts the mud with the same water content as that of embodiment 1, and collects the section of the sediment layer at the same time, but uses a different cutting plate 11 Moving speed.

[0070] A method for collecting a section of a sediment layer in a mud deposition test process, comprising the following steps:

[0071] Steps (1) to (3) are the same as in Example 1;

[0072] (4) Collection of sediment section

[0073] Before collecting the deposition layer, the rotary control valve 4 activates the transmission gearbox 3 to make the first upper blocking plate 8a, the second upper blocking plate 8b, the sealing ring 9 and the steel sheet 10 rise in the second outer cylinder 6b, and then push the deposition cylinder 7 Move upwards, observe the scale 17, and stop rotating the control valve 4 when the sampling posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com