Super-short vertical waveguide coupler with high manufacture tolerance

A coupler and waveguide technology, applied in the field of vertical waveguide couplers, can solve the problems of high manufacturing cost, increase the coupler insertion loss, long length, etc., and achieve the effect of large manufacturing tolerance, shortening length, and increasing coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

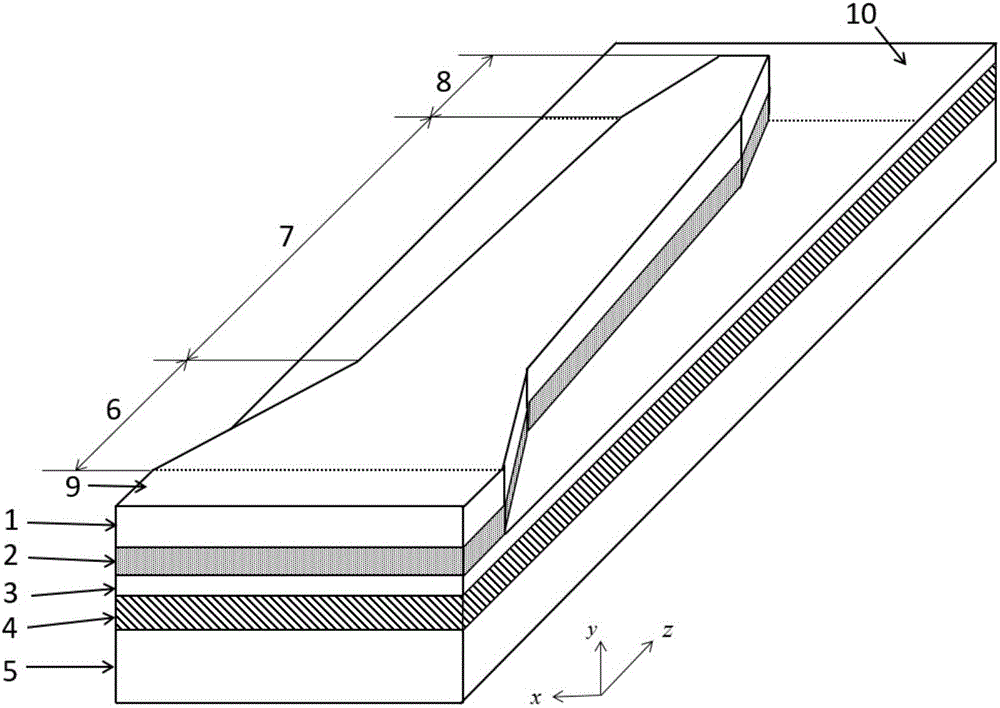

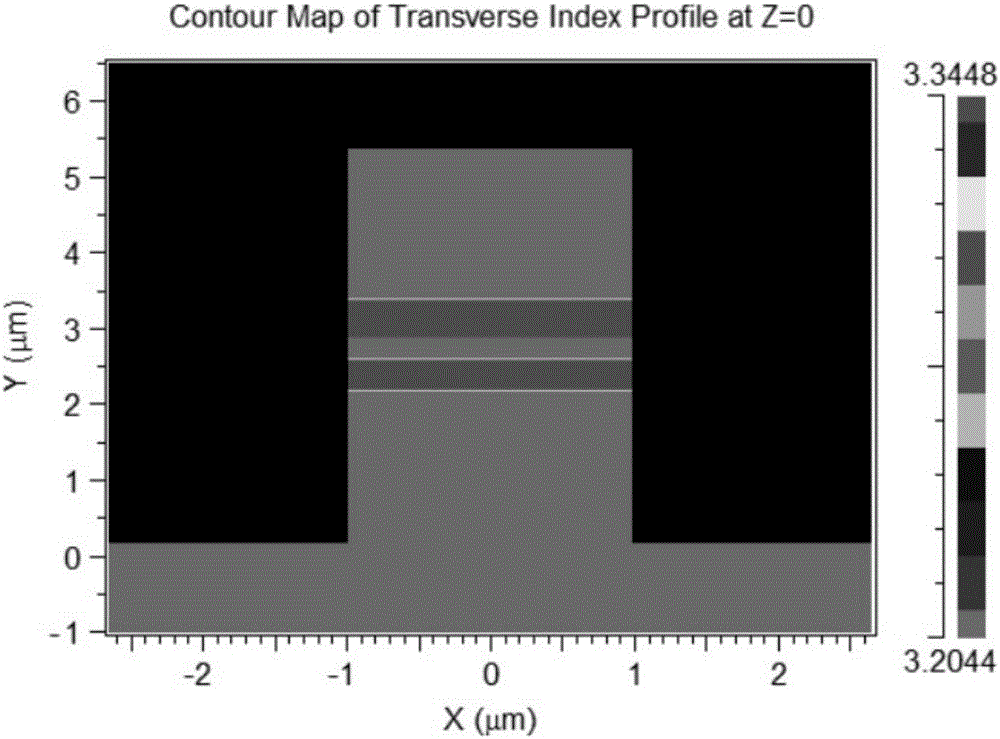

[0028] like figure 1 As shown, there is a side view of the optical waveguide structure of the ultra-short vertical waveguide coupler with a large manufacturing tolerance in the present invention, and the horizontal direction is sequentially composed of a cover layer 1, an upper waveguide layer 2, a spacer layer 3, a lower waveguide layer 4 and a lining layer. The bottom 5 is composed of the spacer layer 3 as a low-refractive index layer between the upper waveguide layer 2 and the lower waveguide layer 4, and the upper and lower waveguides constitute a vertical coupler to gradually couple light from the upper waveguide layer to the lower waveguide layer. In the direction of propagation, it is divided into an input region 9 , a coupling region ( 6 , 7 , 8 ), and an output region 10 .

[0029] In the input region, the mode propagation constant β of the upper waveguide 1 greater than the mode propagation constant β of the lower waveguide 2 , half of the difference between the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com