Method for preparing nano silver organic frame ultrafiltration membrane and method for purifying water using nano silver organic frame ultrafiltration membrane

An organic framework and nano-silver technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of poor removal of micro-pollutants in water, poor compatibility, and biological pollution in the filtration process, achieving short process cycles, Good compatibility and strong universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

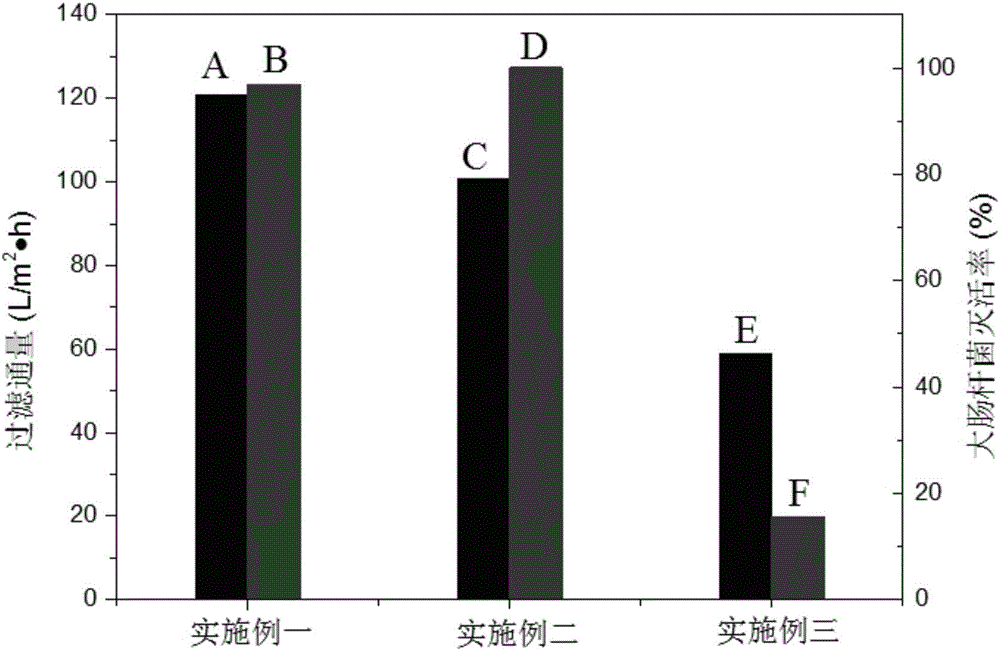

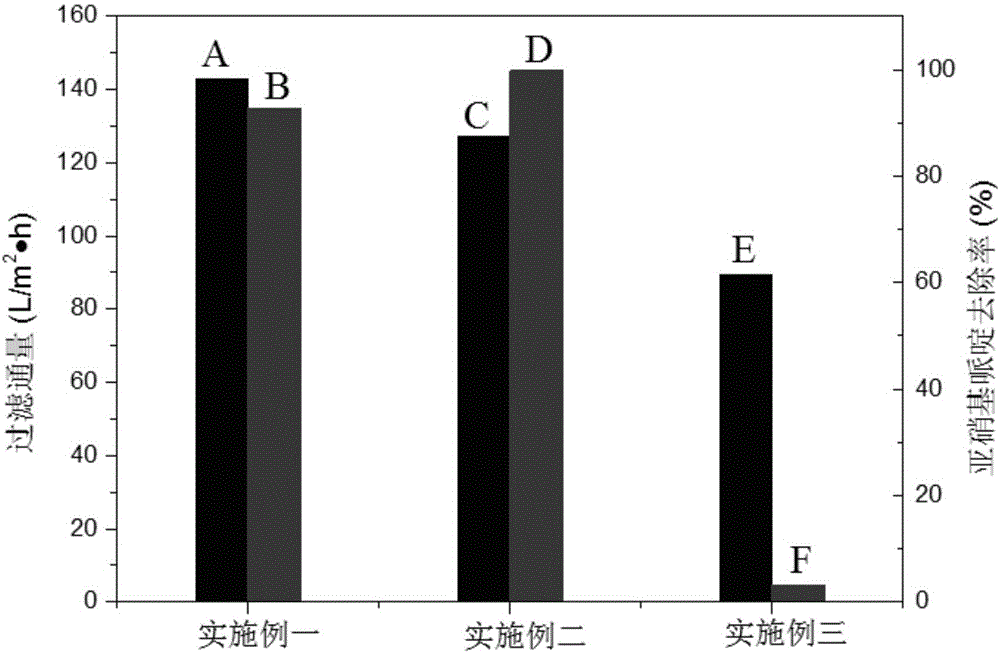

[0028] Embodiment 1: This embodiment is a method for preparing a nano-silver organic framework ultrafiltration membrane, which is specifically completed according to the following steps:

[0029] 1. Prepare the polymer solution: mix the polymer powder with the dispersion solvent I, then stir and react at a stirring speed of 400r / min to 600r / min and a temperature of 50°C to 60°C for 4h to 6h to obtain a polymer solution;

[0030] The mass ratio of polymer powder described in step 1 and dispersion solvent I is 15:(70~85);

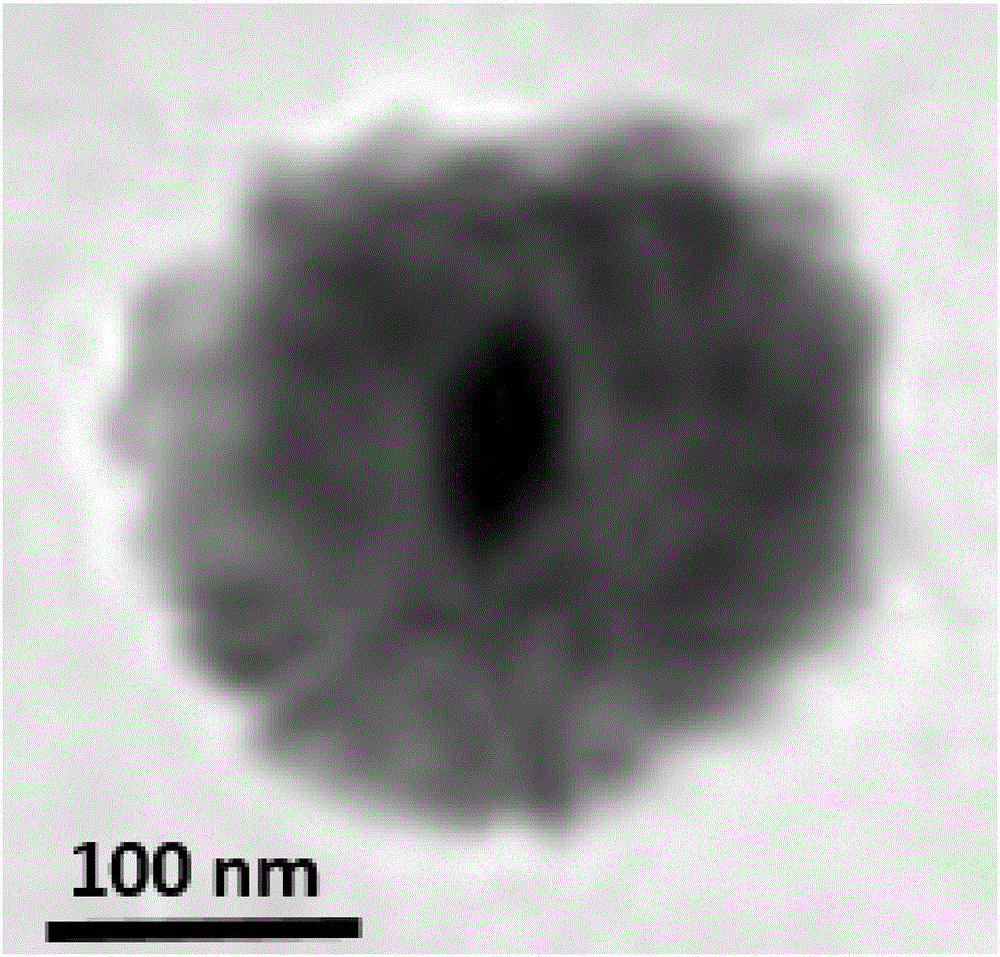

[0031] 2. Preparation of a mixed solution containing nano-silver organic framework: the AgNO 3 . The metal salt of the organic framework and the ligand of the organic framework are dissolved in the dispersion solvent II, and then reacted in a reaction kettle at a temperature of 80°C to 156°C for 0.5h to 24h to obtain a mixed solution containing nano-silver organic framework;

[0032] AgNO as described in step 2 3 The mass ratio to dispersing solvent II is 1...

specific Embodiment approach 2

[0047] Embodiment 2: This embodiment differs from Embodiment 1 in that the polymer described in step 1 is polyvinylidene fluoride, polysulfone, polyethersulfone, cellulose acetate or polyacrylonitrile. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the dispersion solvent I described in step one is N,N-dimethylformamide, 1-methyl-2-pyrrolidone, 1-vinyl-2-pyrrolidone or N,N-dimethylacetamide. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com