On-line detection method for non-contact cutter blade wear

A non-contact, detection method technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problem of low machining accuracy of the workpiece, and achieve the elimination of re-inspection, anti-environmental noise and disturbance, etc. The effect of strong random interference and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

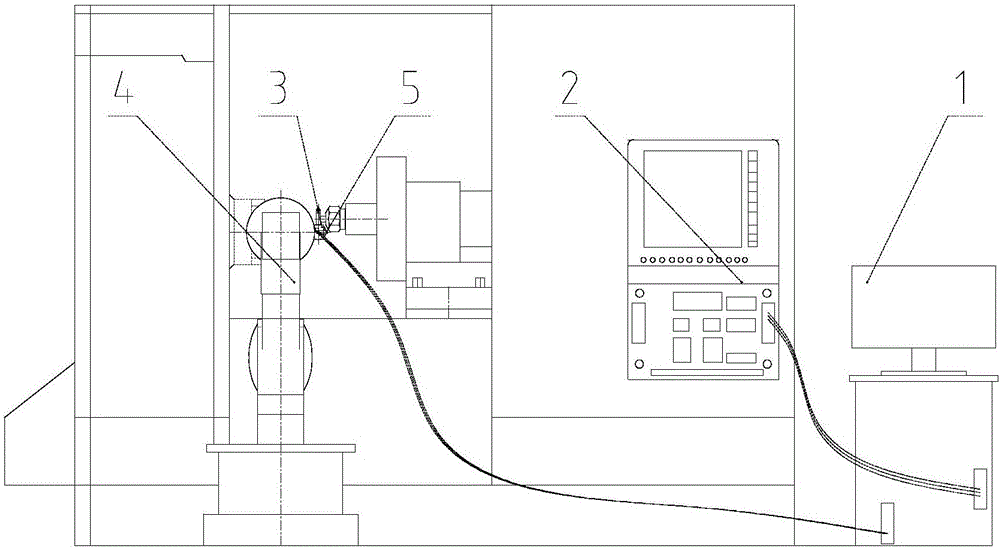

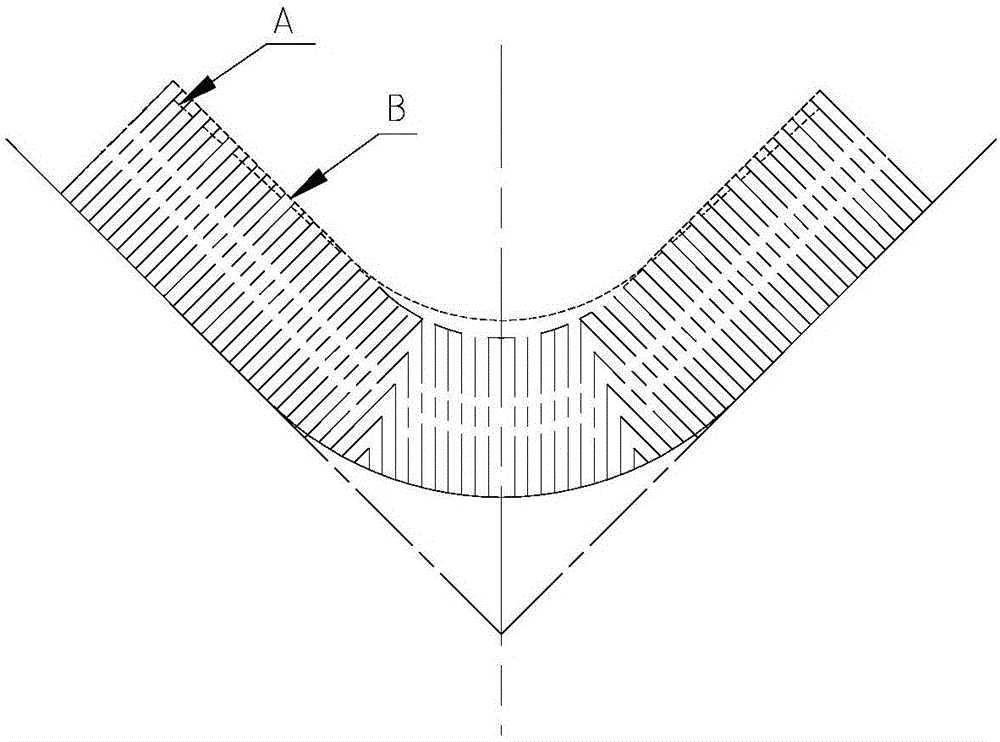

[0015] Depend on figure 1 As shown, a non-contact online detection method for blade wear includes a computer 1 and an industrial camera assembly 3. One end of the computer 1 is connected to the CNC machine tool system 2 through a programming interface, and the other end is connected to a high-resolution computer through a network port. The industrial camera assembly 3 is connected, the industrial camera assembly 3 is fixed on the arm joint of the manipulator 4, the manipulator 4 is fixed on the machine tool, and its arm joint can be rotated, so that the lens of the industrial camera assembly 3 is always aligned with the V-groove tip of the workpiece 5 Corner part; the industrial camera assembly 3 is provided with an industrial lens with high-pixel lenses and an industrial ring light source with adjustable brightness.

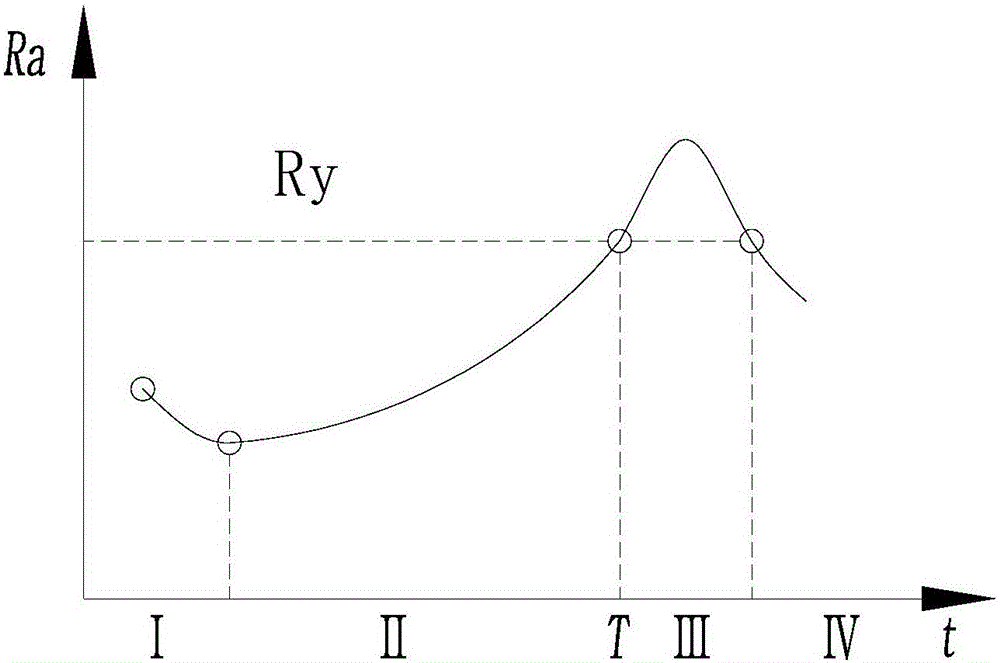

[0016] During machine tool processing, the lens on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com