Hybrid component with a local reinforcement made of a two stage crosslinked composite material based on polyurethane fibre

A component and fiber technology that is used in the production of hybrid components and can solve the problems of maintaining cross-linked state and not having the required metal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

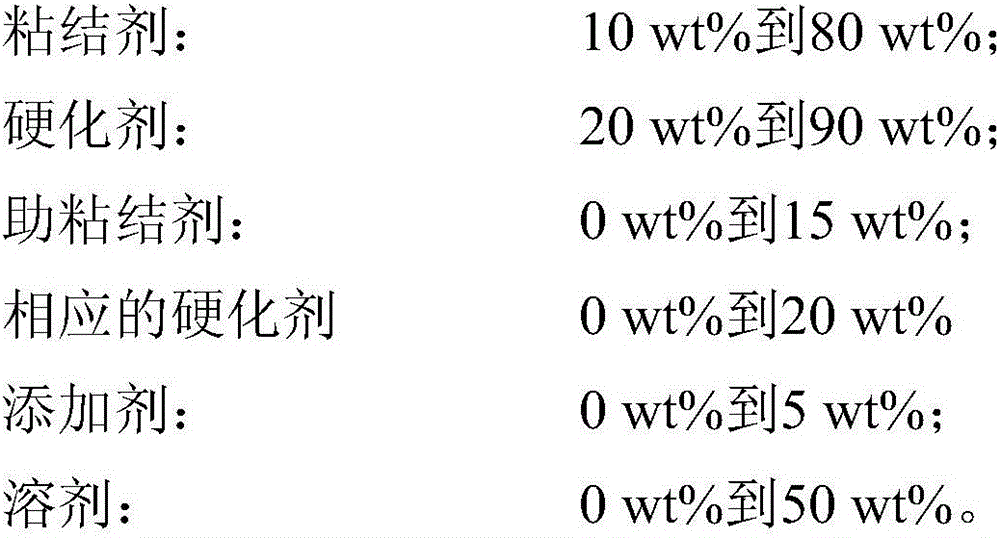

Method used

Image

Examples

Embodiment

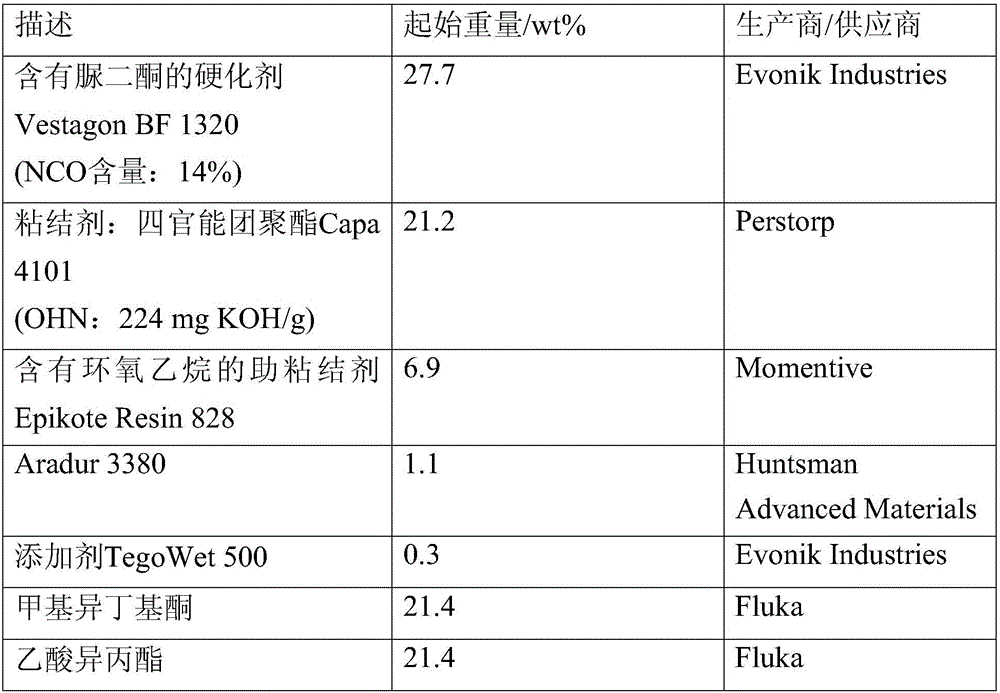

[0117] The present invention will now be explained with reference to examples.

[0118] Torayca FT 300 3K 200tex carbon fiber was processed in all experiments. The fiber is in the form of a twill weave sheet fabric structure Typ Style e452 manufactured by Engineered Cramer Composites (ECC). Basis weight is 200g / m 2 .

[0119] A metal body in the form of a miniature B-pillar supplied by Benteler Automobiltechnik is used. The metal body is made of hot-formed steel (22MnB5 alloy) / easily formable aluminum alloy.

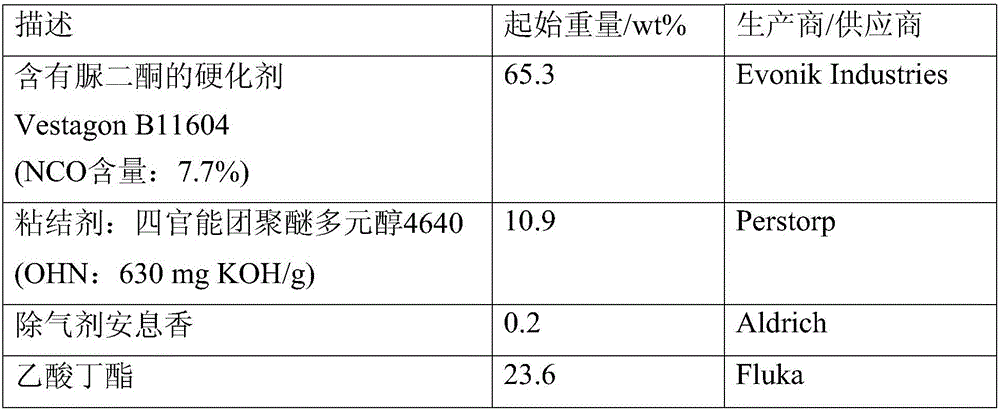

[0120] In Comparative Example 0 which is not the present invention, the reactive polyurethane composition produced according to Example 2 of US2014087613A1 was selected. The formulation is reported in Table 0. Since the binder does not contain polar functional groups selected from ester functional groups, carbonate functional groups, amide functional groups, carbamate functional groups, urea functional groups, thioester functional groups or thiocarbonate functional groups, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com