Permanent magnet electric transmission system of urban trolley car

A tram and electric transmission technology, applied in the direction of electric locomotive, AC induction motor traction, locomotive, etc., can solve the problems of unable to detect system operation data in real time, limited capacity of tram DC power grid capacity, etc., to avoid further expansion of faults , Satisfy the effect of operation reliability and protection circuit safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

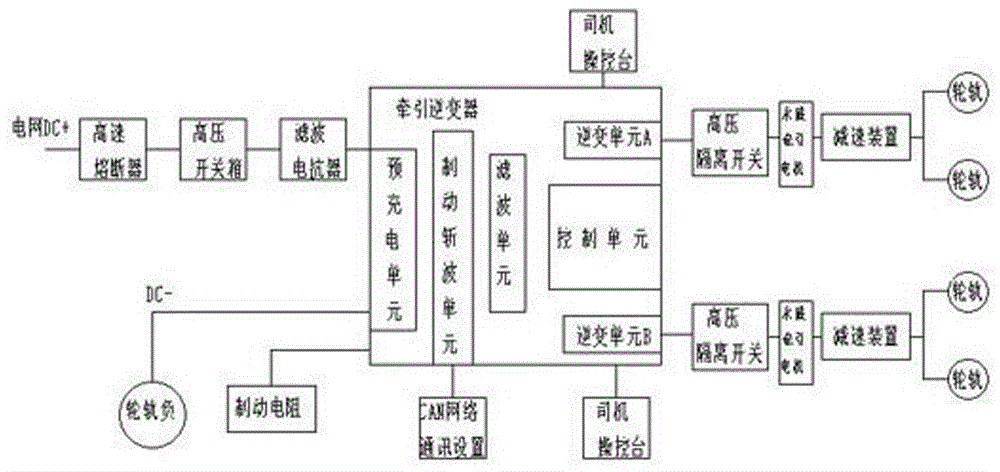

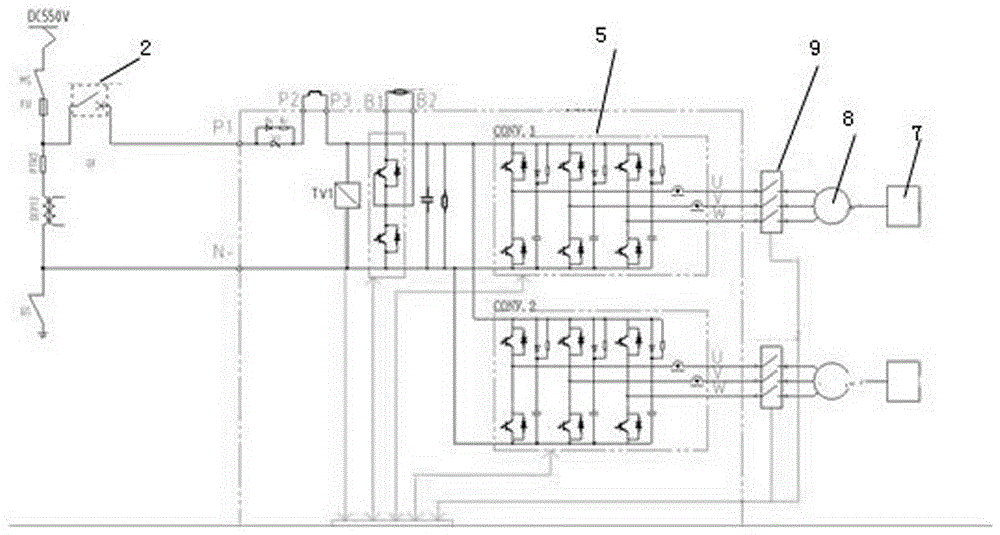

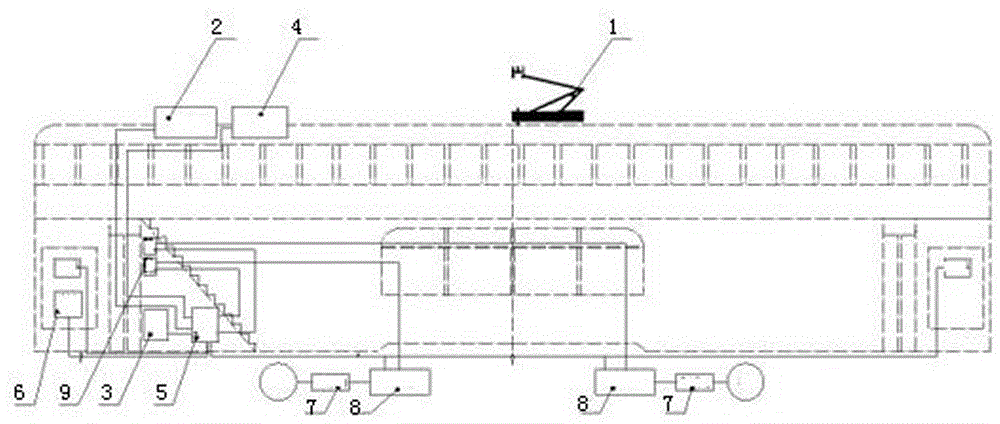

[0014] A permanent magnet electric transmission system for an urban tram, comprising a high-speed fuse, a high-voltage switch box 2, a filter reactor 3, a braking resistor 4, a traction inverter 5, a CAN network communication device 6, a deceleration device 7, a permanent magnet The traction motor 8 and the high-voltage isolating switch 9, the input end of the traction inverter 5 are respectively connected with the braking resistor 4, the CAN network communication device 6 and one end of the filter reactor 3, and the other end of the filter reactor 3 passes through the high-voltage switch box 2 Connected with a high-speed fuse, the traction inverter 5 includes a pre-charging unit, a brake chopper unit, a filter unit, an inverter unit A, an inverter unit B and a control unit, and the output of the inverter unit A passes through a high-voltage isolation switch 9 is connected to the input end of one of the permanent magnet traction motors 8, the output end of the inverter unit B i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com