Inner circulation film formation method of aerobic and salt-resisting denitrifying bacteria and denitrifying reactor

A technology of denitrifying bacteria and film hanging method, applied in the field of water treatment, can solve the problems of long time of biofilm, low impact load resistance, complicated operation, etc., to achieve the effect of easy operation, increase the fixed amount, and increase the film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

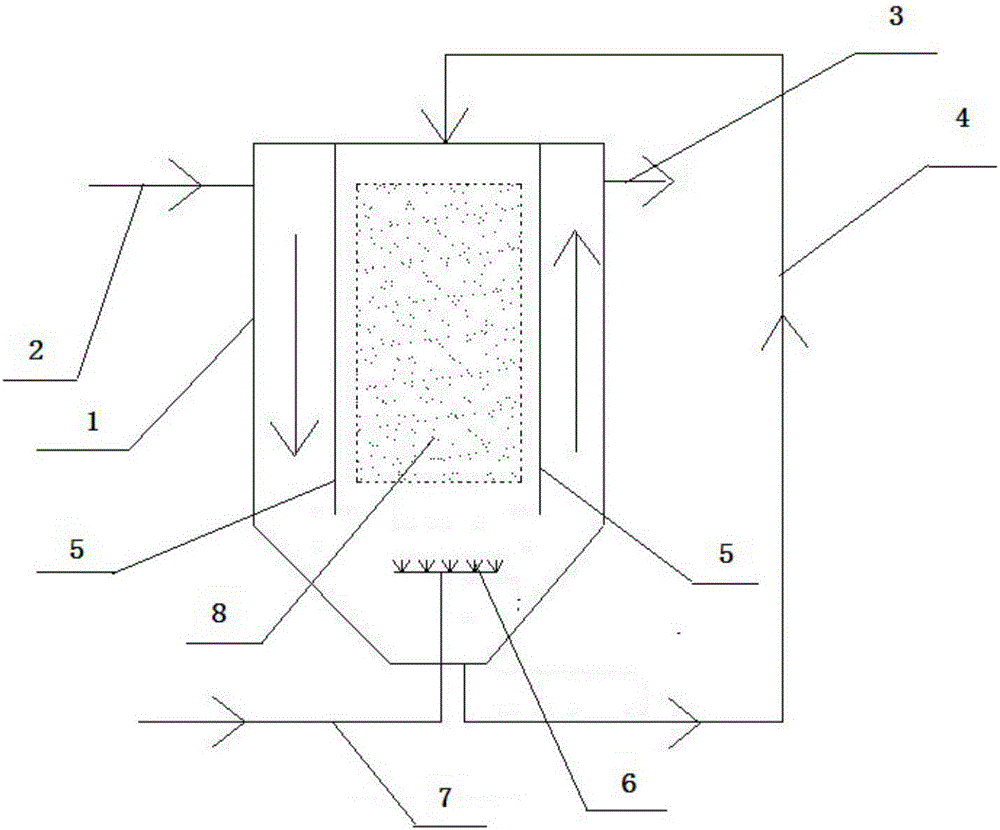

[0031] Embodiment 1, a kind of internal circulation type denitrification reactor:

[0032] refer to figure 1 , refer to figure 1 , including the reactor body 1, the reactor body 1 is provided with a deflector 5 to longitudinally divide it into three spaces, which are respectively the water inlet area, the biological filler and the water outlet area, and the upper part of the water inlet area is connected with the water inlet pipeline 2 , the upper part of the water outlet area is connected with the water outlet pipeline 3, and a biological filler 8 is arranged in the biological filler area;

[0033] An aeration head 6 is provided at the bottom of the reactor body 1, and the aeration head 6 is connected with an aeration pipeline 7 leading into the reactor body 1; the aeration pipeline 7 is connected with an aeration device;

[0034] A denitrification sludge return pipeline 4 leading to the top of the reactor body 1 is also connected to the bottom of the reactor body 1 .

Embodiment 2

[0035] Example 2, the internal circulation denitrification reactor described in Example 1: the upper part of the reactor body 1 is cylindrical, and the lower part is conical.

Embodiment 3

[0036] Embodiment 3, a method for film-forming of aerobic and salt-tolerant denitrifying bacteria in internal circulation: using the internal circulation denitrification reactor described in Embodiment 1 or 2 to realize rapid film-forming of aerobic and salt-tolerant denitrifying bacteria; Including the following process steps:

[0037] (1) Filling with biological filler: first add biological filler into the denitrification reactor, and the filling volume is 60% of the effective volume of the reactor;

[0038] (2) Bacteria inoculation: After inoculating 5000 mg / L aerobic and salt-tolerant denitrification bacteria into the denitrification reactor, expose for 12 hours;

[0039] (3) Filming in the reactor: when there is no sludge loss in the reactor, the aeration device is turned on, artificially simulated wastewater is used to start continuous water inflow, and the temperature and dissolved oxygen of the reactor are controlled. The initial mixed concentration of nitrate and nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com