Building mixture containing FS101 mortar waterproof agent

A technology of FS101 and waterproofing agent, which is applied in the field of building mixtures, can solve the problems of reducing mortar shrinkage, etc., and achieve the effects of reducing mortar shrinkage, good dispersion, and avoiding difficulty in uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

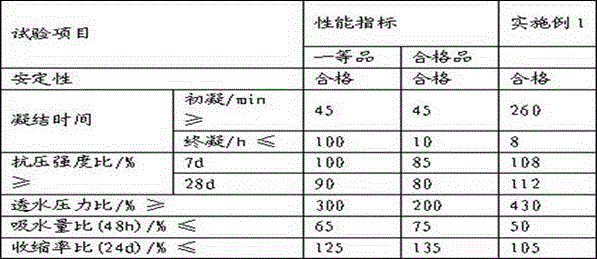

[0016] In this example, the construction mixture containing FS101 mortar waterproofing agent is made by mixing FS101 mortar waterproofing agent, ordinary Portland cement, sand and water; wherein, FS101 mortar waterproofing agent and water are mixed according to the weight ratio of 1:250 to form FS101 mortar waterproofing agent dilution; the preparation process of the waterproof mortar is as follows: cement:sand:FS101 mortar waterproofing agent dilution is mixed according to the weight ratio of 1:3:0.45. The strength grade of ordinary Portland cement in this example is 42.5. The sand is medium sand, the mud content is less than or equal to 1wt%, the sulfide content is less than or equal to 1wt%, and the sulfate content is less than or equal to 1wt%. The performance test results of the formed waterproof layer are shown in Table 1. It can be seen from Table 1 that its performance meets the requirements of the JC474-2008 standard.

[0017] Table 1

[0018]

Embodiment 2

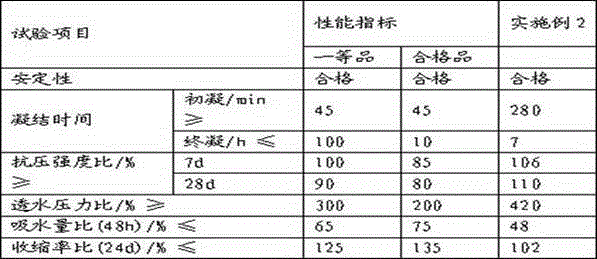

[0020] In this example, the construction mixture containing FS101 mortar waterproofing agent is made by mixing FS101 mortar waterproofing agent, ordinary Portland cement, sand and water; wherein, FS101 mortar waterproofing agent and water are mixed according to the weight ratio of 1:250 to form FS101 mortar waterproofing agent dilution; the preparation process of the waterproof mortar is as follows: cement:sand:FS101 mortar waterproofing agent dilution is mixed according to the weight ratio of 1:2:0.55. The strength grade of ordinary Portland cement in this example is 42.5R. The sand is medium sand, the mud content is less than or equal to 1wt%, the sulfide content is less than or equal to 1wt%, and the sulfate content is less than or equal to 1wt%. The performance test results of the formed waterproof layer are shown in Table 2. It can be seen from Table 2 that its performance meets the requirements of the JC474-2008 standard.

[0021] Table 2

[0022]

Embodiment 3

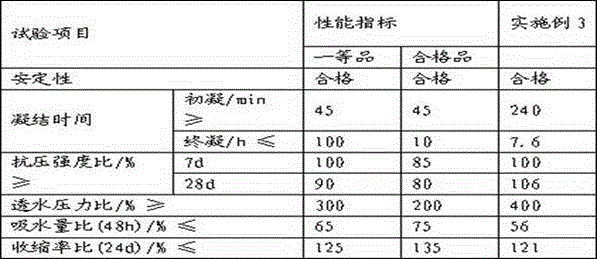

[0024] In this example, the construction mixture containing FS101 mortar waterproofing agent is made by mixing FS101 mortar waterproofing agent, ordinary Portland cement, sand and water; wherein, FS101 mortar waterproofing agent and water are mixed according to the weight ratio of 1:200 to form FS101 mortar waterproofing agent dilution; the preparation process of the waterproof mortar is as follows: cement:sand:FS101 mortar waterproofing agent dilution is mixed according to the weight ratio of 1:3:0.50. The strength grade of ordinary Portland cement in this example is 52.5. The sand is medium sand, the mud content is less than or equal to 1wt%, the sulfide content is less than or equal to 1wt%, and the sulfate content is less than or equal to 1wt%. The performance test results of the formed waterproof layer are shown in Table 3. It can be seen from Table 3 that its performance meets the requirements of the JC474-2008 standard.

[0025] table 3

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com