A strain of Gluconacetobacter high-yielding phenyllactic acid and its preparation method for phenyllactic acid

A technology of Gluconacetobacter and phenyllactic acid, applied in the field of food biology, can solve the problems of difficult industrial production of phenyllactic acid, unreported research, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

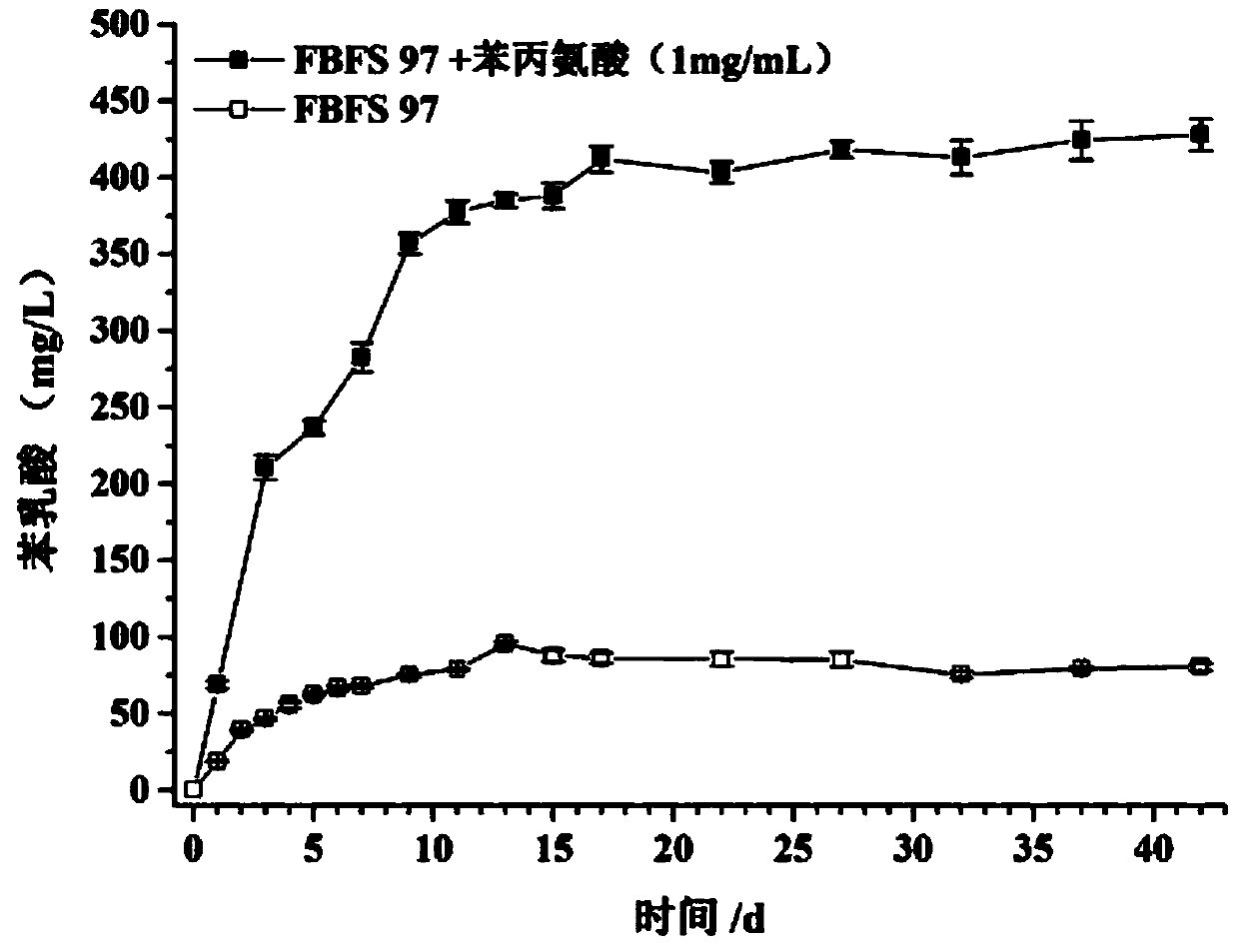

[0022] The influence of fermentation time on the content of phenyllactic acid in the fermentation broth: According to the method described in the instructions, the content of phenyllactic acid in the fermentation broth of Staphylococcus acetobacter FBFS 97 was detected by high performance liquid chromatography at different fermentation times, and it was found that the content of phenyllactic acid in the fermentation broth was not added and phenylalanine was added. Under the two conditions of acidity and acidity, the content of phenyllactic acid in the fermentation broth first increased and then remained the same as the fermentation time progressed. In the fermentation broth without adding phenylalanine, the highest phenyllactic acid can reach 95.71mg / L (fermentation 13d), and in the fermentation broth with 1mg / mL phenylalanine, the highest phenyllactic acid can reach 412.05mg / L ( Fermentation 17d)( figure 1 ).

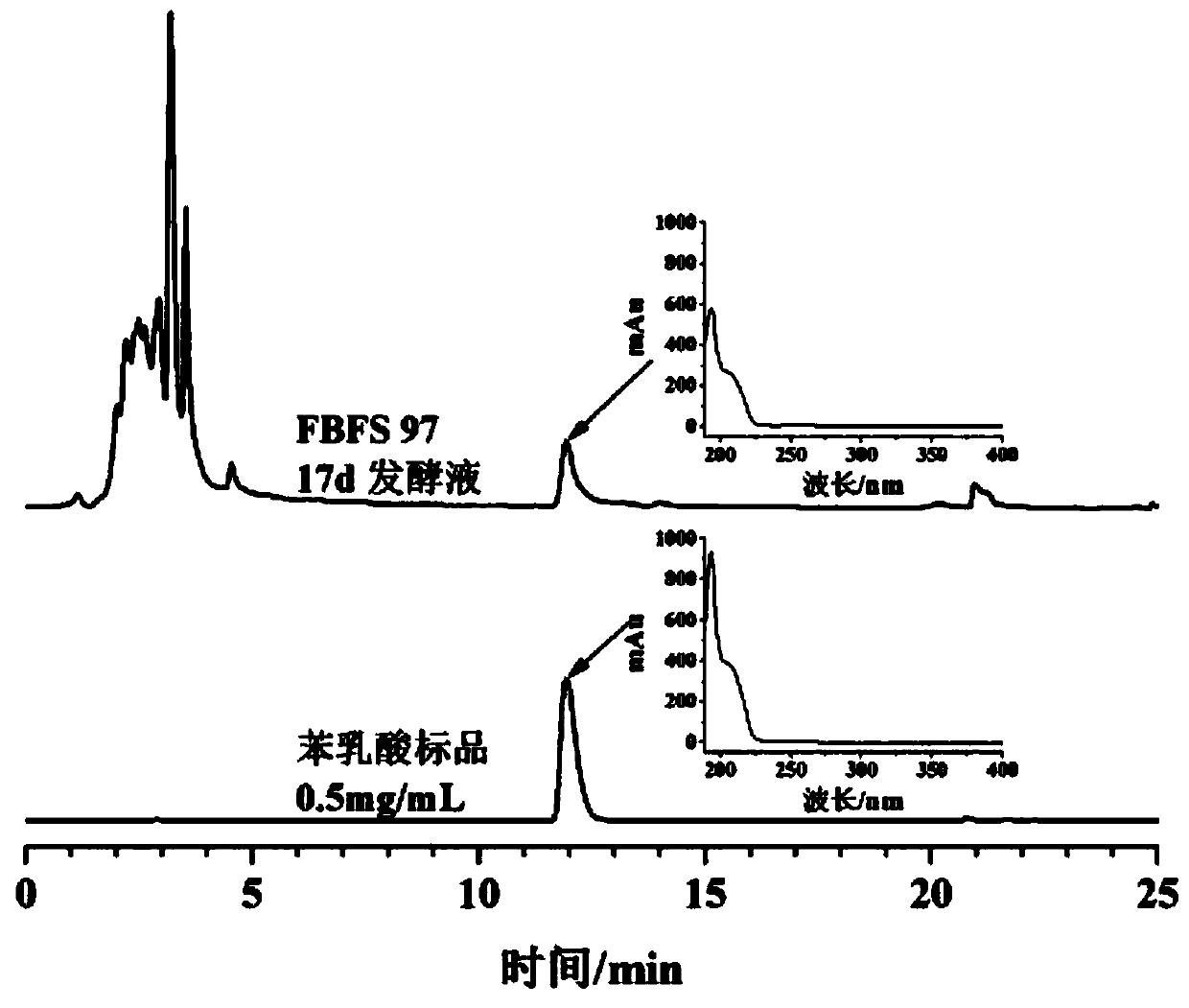

[0023] The high-performance liquid chromatography method for det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com