Marine fixing platform and mounting method thereof

A technology for fixing platforms and auxiliary devices, which is applied in water conservancy projects, artificial islands, underwater structures, etc., and can solve the problem that engineering floating cranes cannot implement butt welding of waterproof casings, and the overall fixed platform cannot meet the technical level and requirements , engineering and drilling and completion interface intersection and other issues, to achieve the effect of short span of construction period, shortened construction time, and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

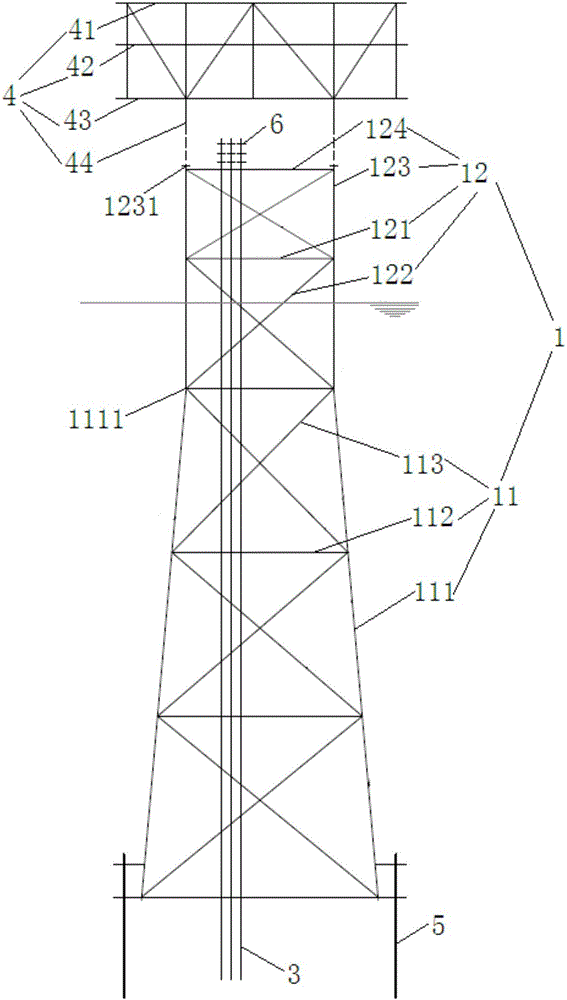

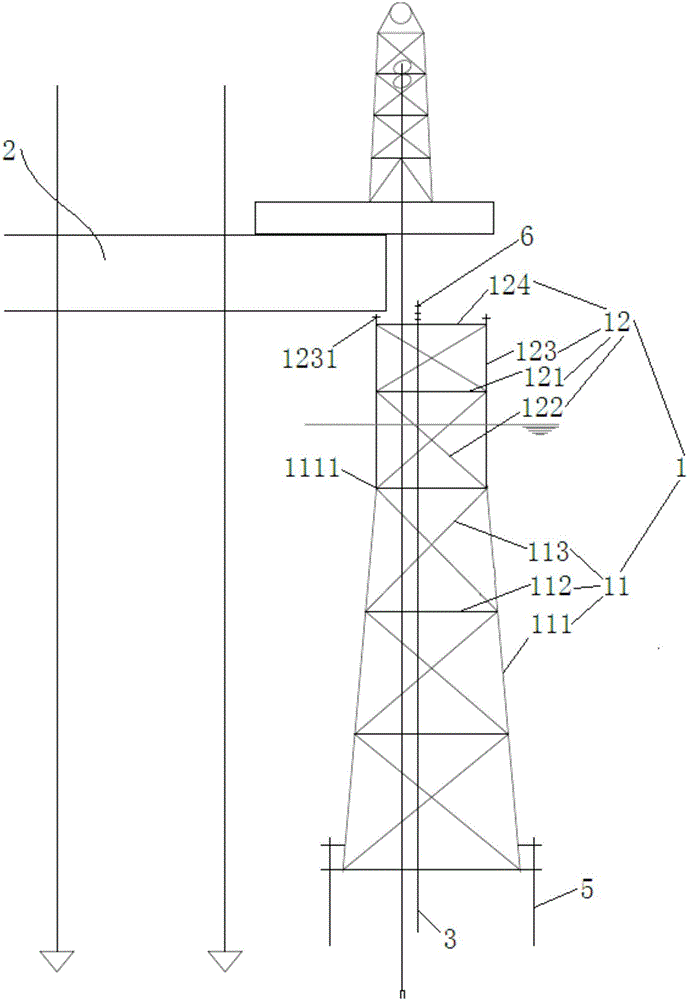

[0020] like figure 1 As shown, the offshore fixed platform proposed by the present invention includes a chimney jacket 1 fixedly arranged in the target sea area. For use with Drillship 2 (eg figure 2 As shown), the auxiliary drilling device 12 is matched, and the top of the auxiliary drilling device 12 is higher than the sea level. The jacket body 11 is a frame formed by fixedly connecting jacket thighs 111 , jacket horizontal braces 112 and jacket elevation oblique braces 113 . The auxiliary drilling device 12 includes a frame formed by fixed connection of horizontal supports 121 , longitudinal inclined supports 122 and column support legs 123 , and a drilling deck 124 is fixedly arranged on the top of the frame. Wherein, the bottom of the column support leg 123 is tightly connected with the position of the working point 1111 on the top of the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com