Installation method of foundation bolts in wet papermaking workshop

A technology of foundation bolts and installation methods, which is applied in infrastructure engineering, construction, etc., can solve the problems of delayed installation period, high installation accuracy requirements, inaccurate bolt positions, etc., and achieves the effect of saving construction costs, ensuring accuracy, and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

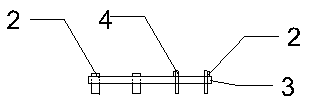

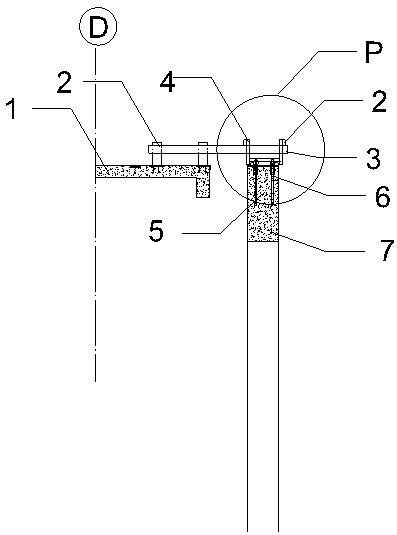

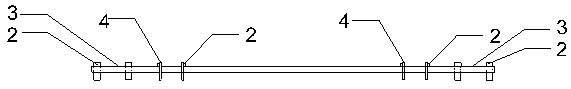

[0050] The construction process of the foundation bolt installation method of the wet papermaking workshop of the present invention:

[0051] Construction preparation→laying out and positioning→fabrication and installation of fixed combined frame→installation of bolt fixing plate→installation, adjustment and fixing of anchor bolts→installation of foundation beam side form→concrete pouring→reinspection and handover of foundation bolts.

[0052] The method for installing foundation bolts in a wet papermaking workshop of the present invention comprises the following steps:

[0053] a. Construction preparation, including the following steps:

[0054] 1) Two concrete platforms at a height of 7.5m are used as the basis for bolt-mounted and fixed composite frames, and a number of concrete iron parts are pre-embedded on the equipment transmission side and equipment operation side respectively for welding and fixing the composite frame. The distance between the concrete platforms is 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com