Variable speed motor and constant-power variable displacement pump matched hydraulic energy-saving system and control method

A constant power variable, hydraulic system technology, applied in the direction of pump control, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of complex collection of information, high cost, lengthy data processing, etc., and achieve simple control mode and low cost , Improve the effect of energy-saving defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

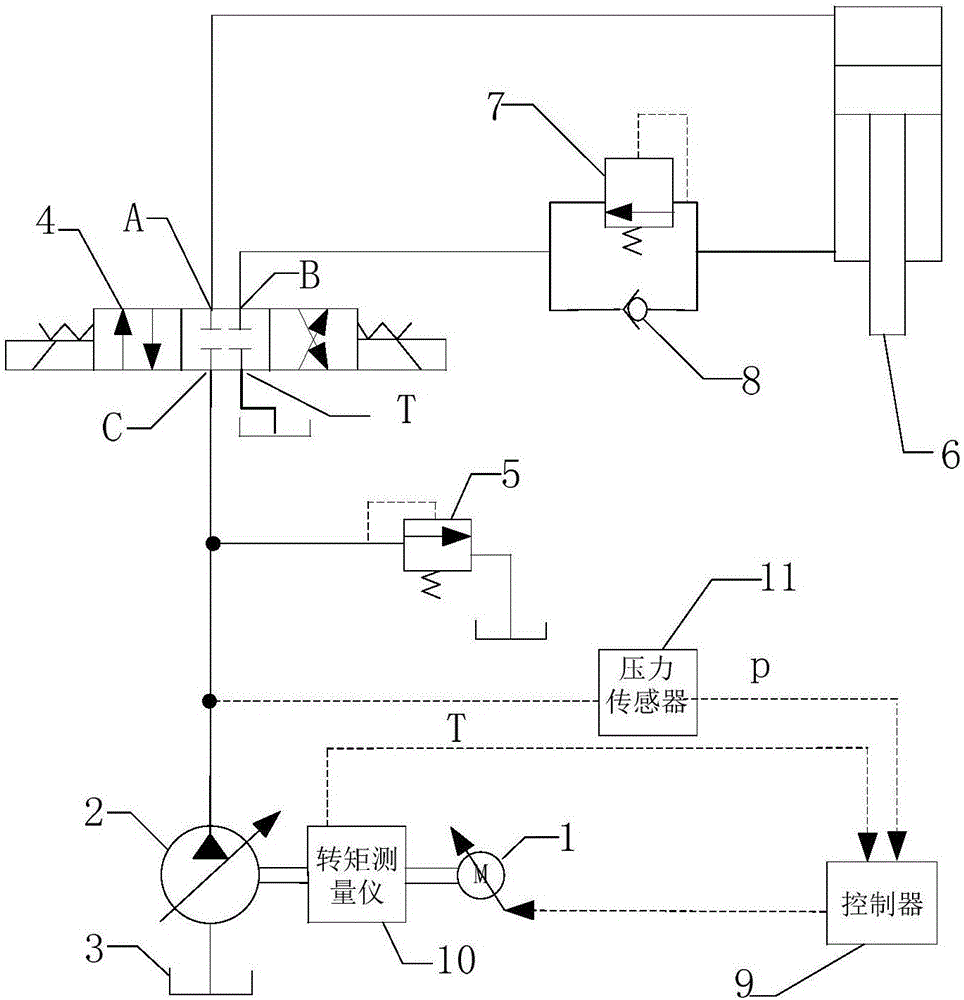

[0023] see figure 1 In this embodiment, the hydraulic energy-saving system matching the variable speed motor and the constant power variable pump includes a hydraulic system and a control system.

[0024] The hydraulic system includes a variable frequency motor 1 with adjustable speed and a constant power variable pump 2 coaxially connected to the variable speed motor 1; the oil inlet of the constant power variable pump 2 is connected to the oil tank 3, and the oil outlet of the constant power variable pump 2 is connected to the The oil port C of the three-position four-way electromagnetic reversing valve 4 with the function of neutral unloading is connected, the other way is connected with the inlet of the first relief valve 5, and the oil outlet of the first relief valve 5 is connected with the oil tank 3; The oil return port T of the three-position four-way electromagnetic reversing valve 4 is connected to the fuel tank 3, the oil outlet A of the three-position four-way ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com