Spiral bevel gear long-life drive fatigue reliability design method based on grinding and heat treatment

A technology of a spiral bevel gear and a design method, which is applied in the direction of electrical digital data processing, computer-aided design, design optimization/simulation, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0073]The number of teeth on the small wheel is 26, the number of teeth on the large wheel is 31, the modulus of the big end is 8.654mm, the tooth width is 57mm, the midpoint helix angle is 35°, the pressure angle is 20°, the transmission power is 1051KW, the input speed is 2200r / min, the service life is 500h, and the accuracy level is 6 Grade, the surface roughness of the small wheel is 0.8, the surface roughness of the large wheel is 0.8, and the viscosity of the lubricating oil at 40°C is 177.2mm 2 / s, the gear material is carburized and quenched carburized steel, the material hardness is HRC59, the tensile limit is 1180MPa, the contact fatigue limit is 1500MPa, the bending fatigue limit is 480Mpa, and the material density is 7.88E-6kg / mm 3 , elastic modulus 2.07E+5MPa, Poisson's ratio 0.3.

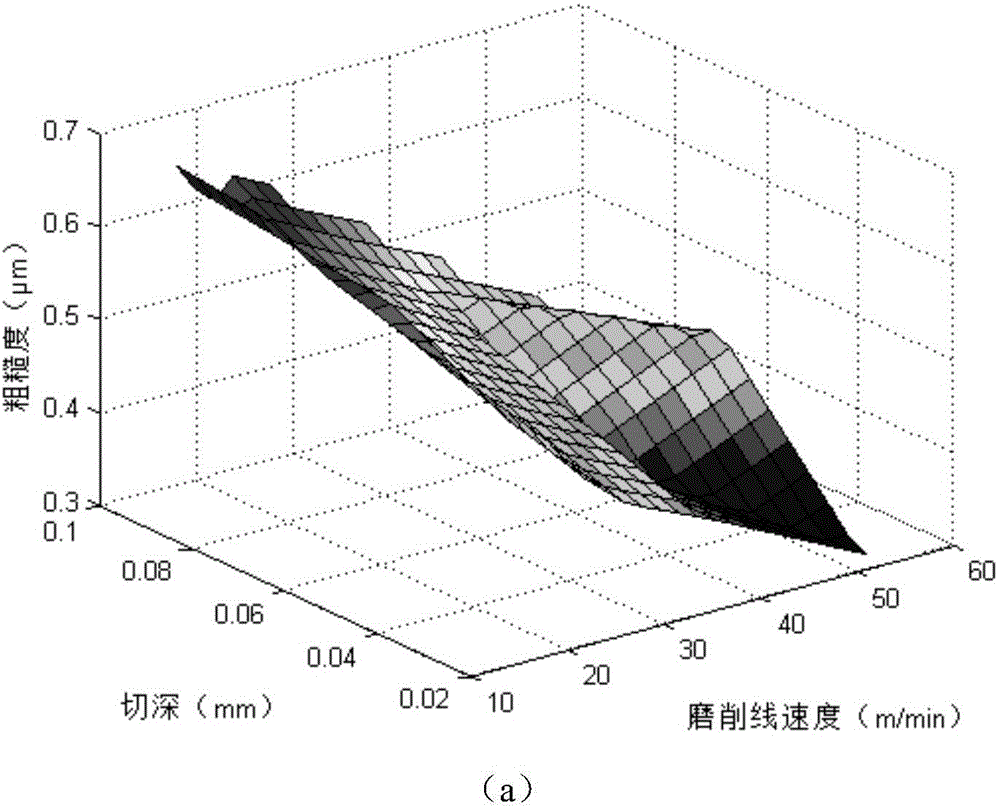

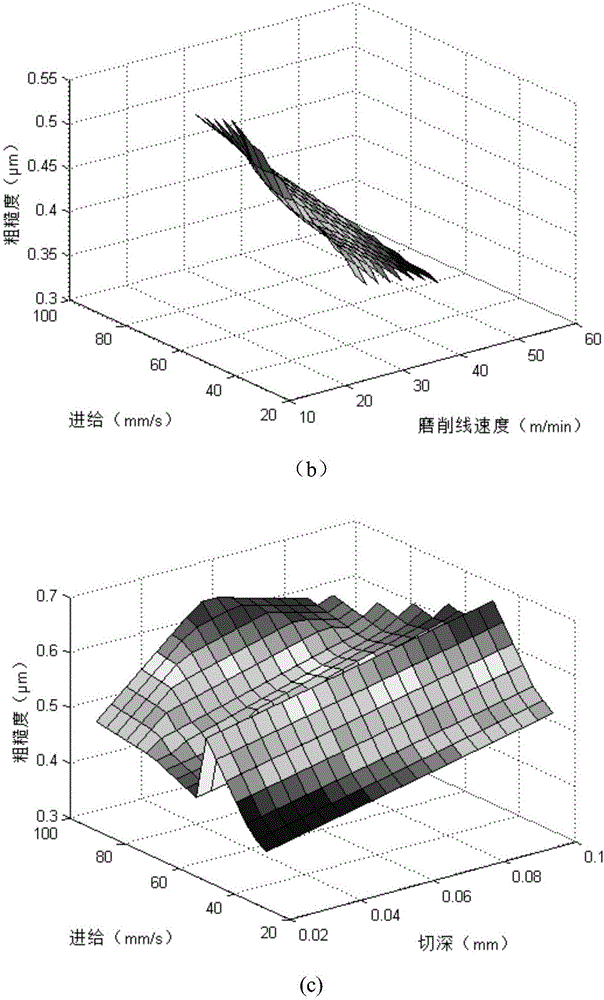

[0074] Step (1) study the influence law of grinding process parameters on tooth surface roughness and residual stress;

[0075] Taking the study of the influence of grinding process p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com