a c-based n Method and System for Determining Critical Speed of Steam Turbine Rotor by Group Theory

A steam turbine rotor, critical speed technology, applied in geometric CAD, CAD numerical modeling, special data processing applications, etc., can solve problems such as difficult calculation, huge solution scale, calculation method and actual value error, etc., to achieve a clear operation process. , the effect of ensuring calculation accuracy and reducing calculation scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

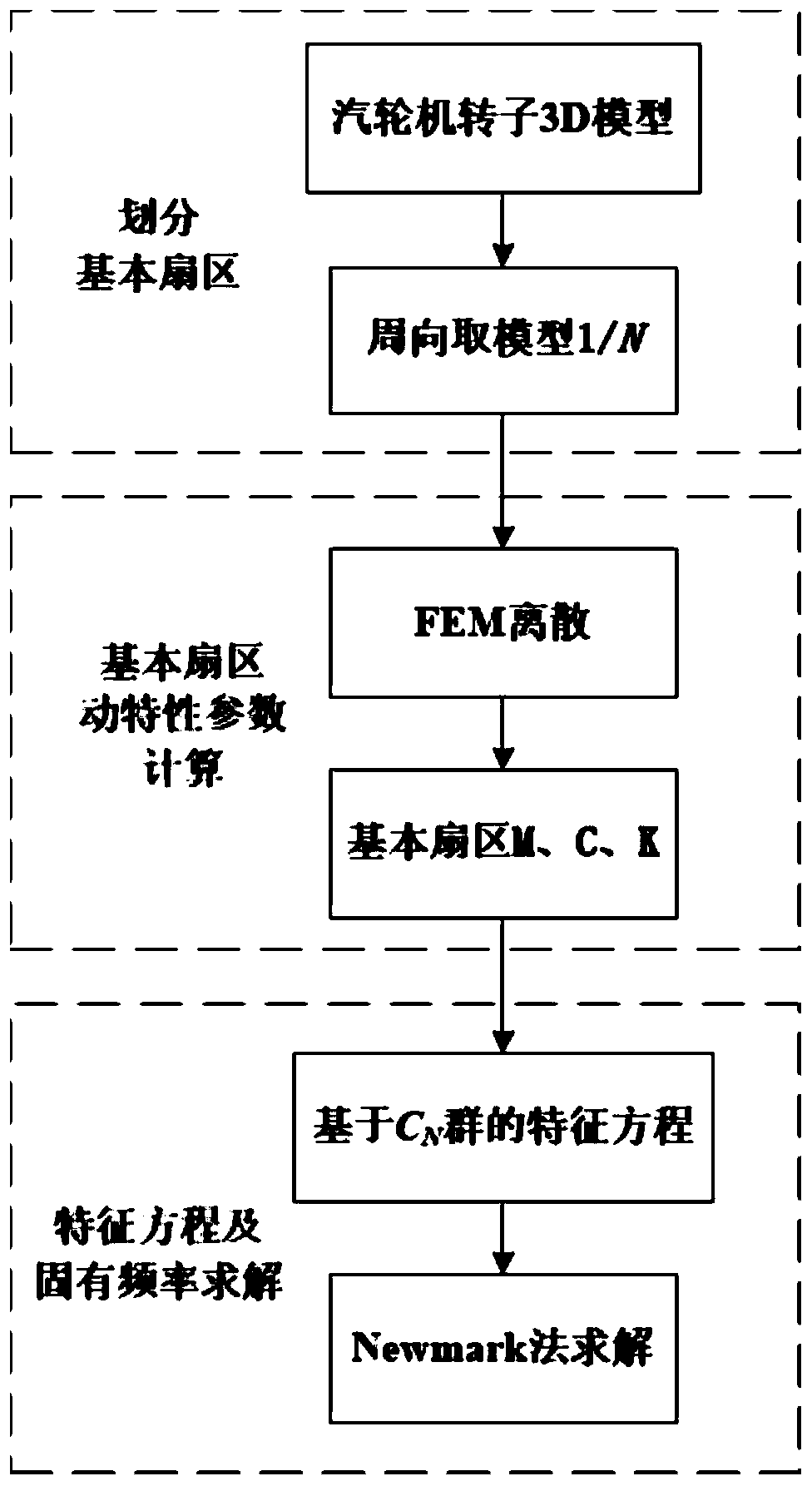

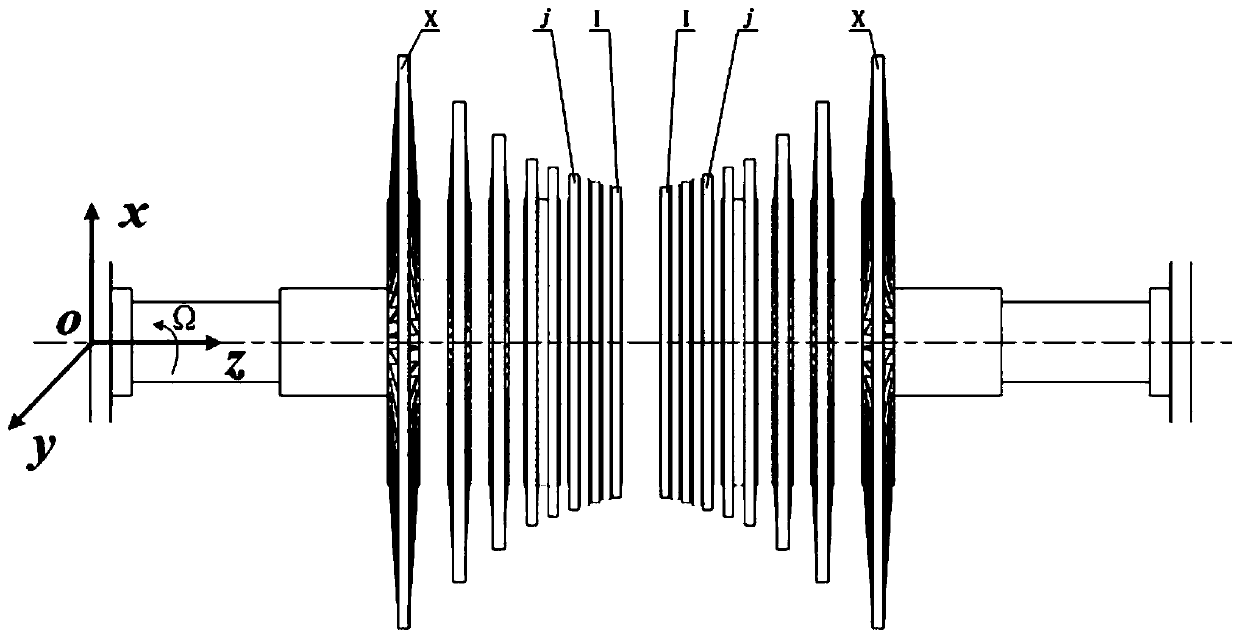

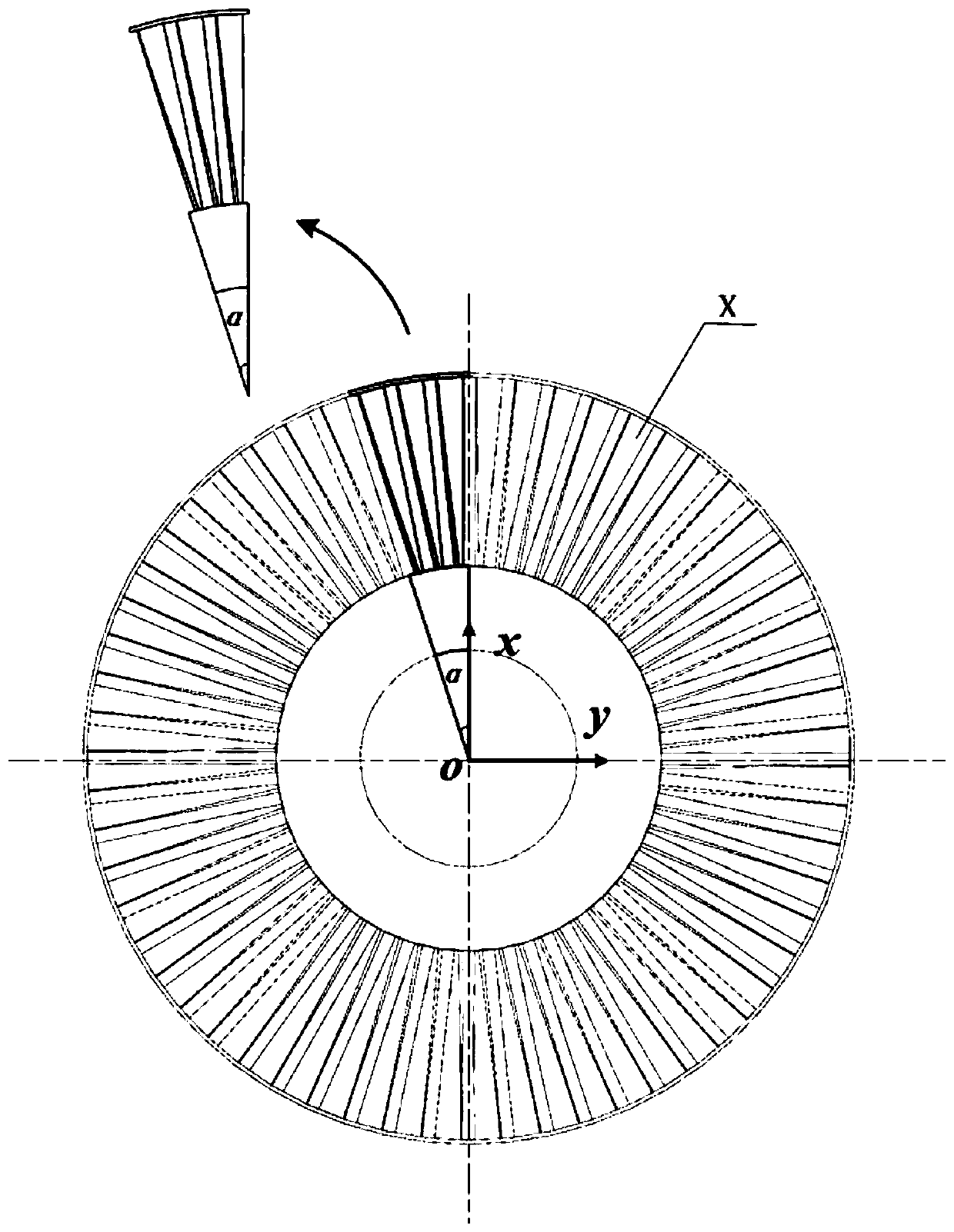

[0032] like figure 1 As shown, the present invention is based on C N The method of group theory to calculate the critical speed of steam turbine rotor is mainly completed through three modules: basic sector creation module, basic sector dynamic characteristic parameter calculation module, dynamic modeling and solution module. Each module performs data processing sequentially. First, take 1 / N of the geometric model of the steam turbine rotor in the circumferential direction as the basic sector, and then use the finite element method to discretize the basic sector to obtain its dynamic characteristic parameters; The lower-order steam turbine rotor characteristic equations characterized by characteristic parameters are used to obtain the required critical speeds of each order.

[0033] The data processing of each module is realized through the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com