A kind of amorphous alloy transformer and preparation method of amorphous alloy strip

A technology of amorphous alloys and transformers, applied in the field of amorphous alloy transformers, can solve the problems of large iron loss and low saturation magnetization, achieve the effects of reducing core loss, excellent core loss, and avoiding tripping accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

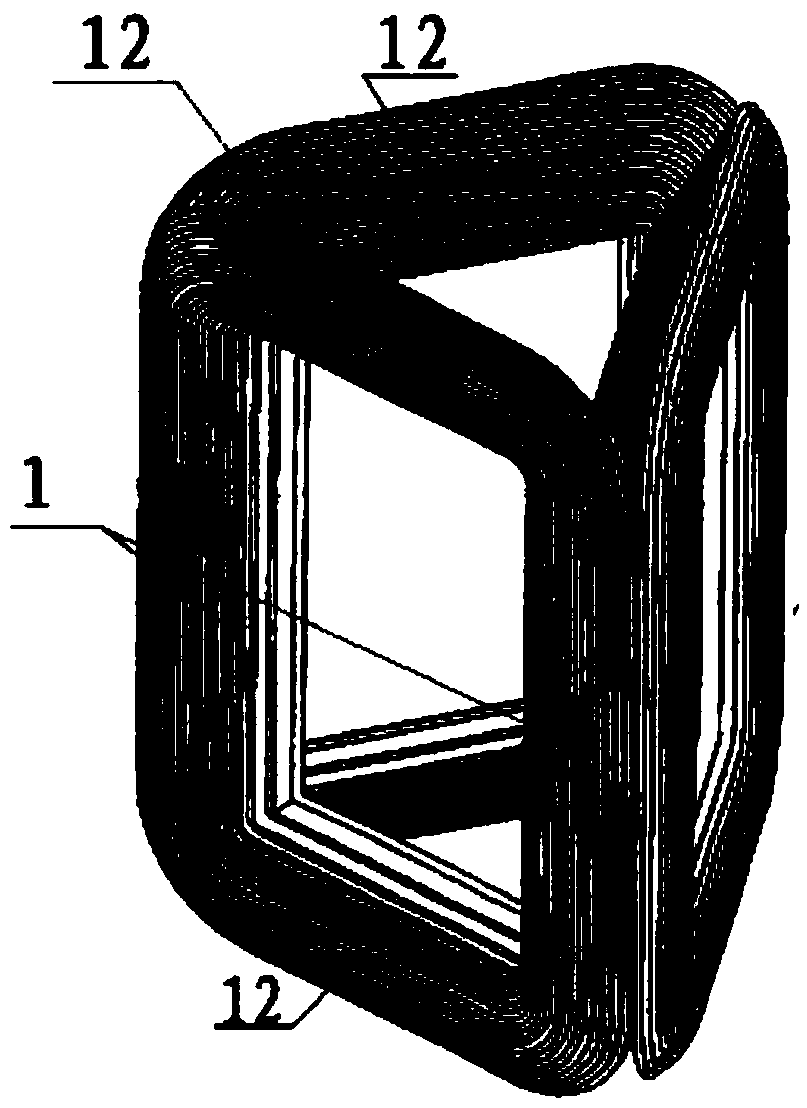

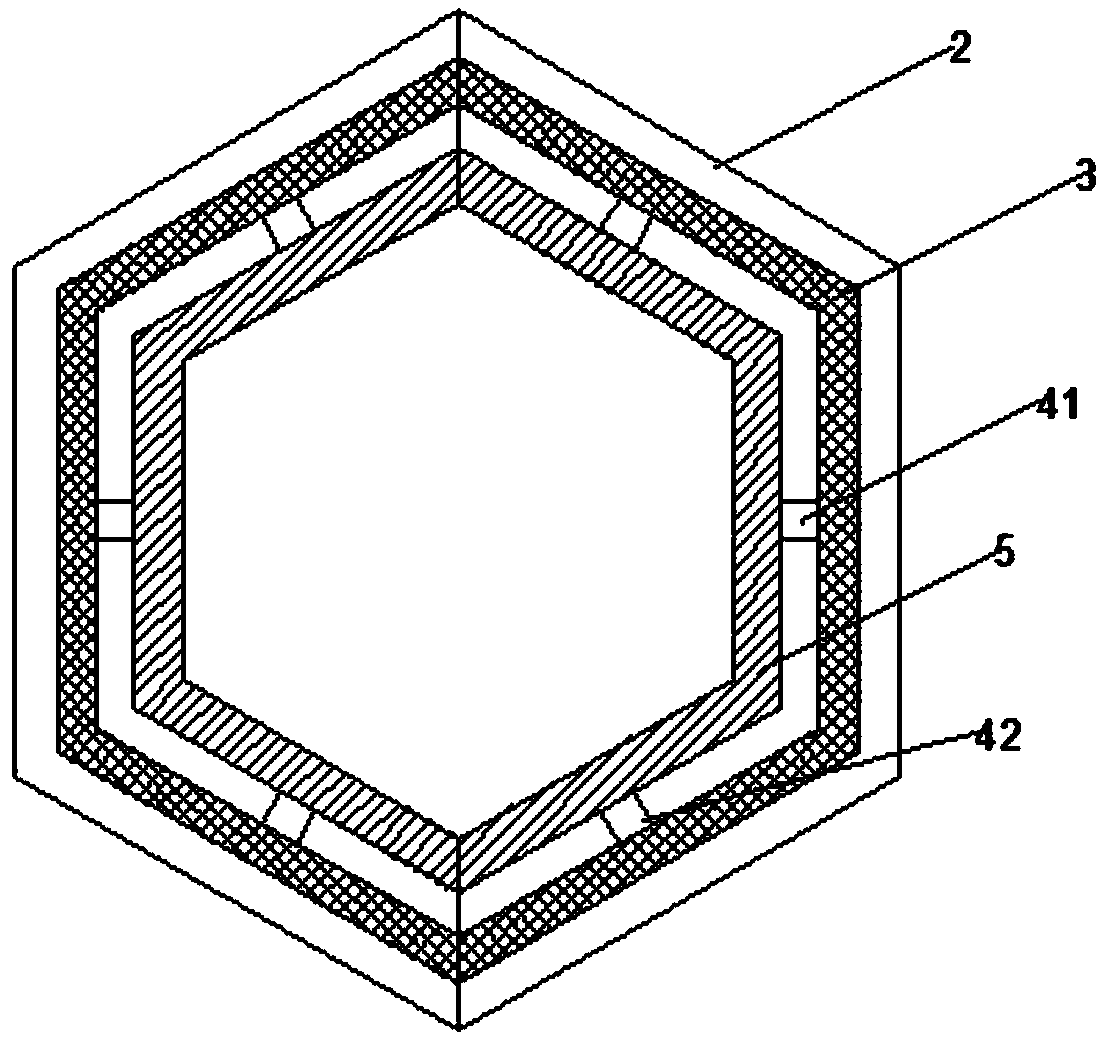

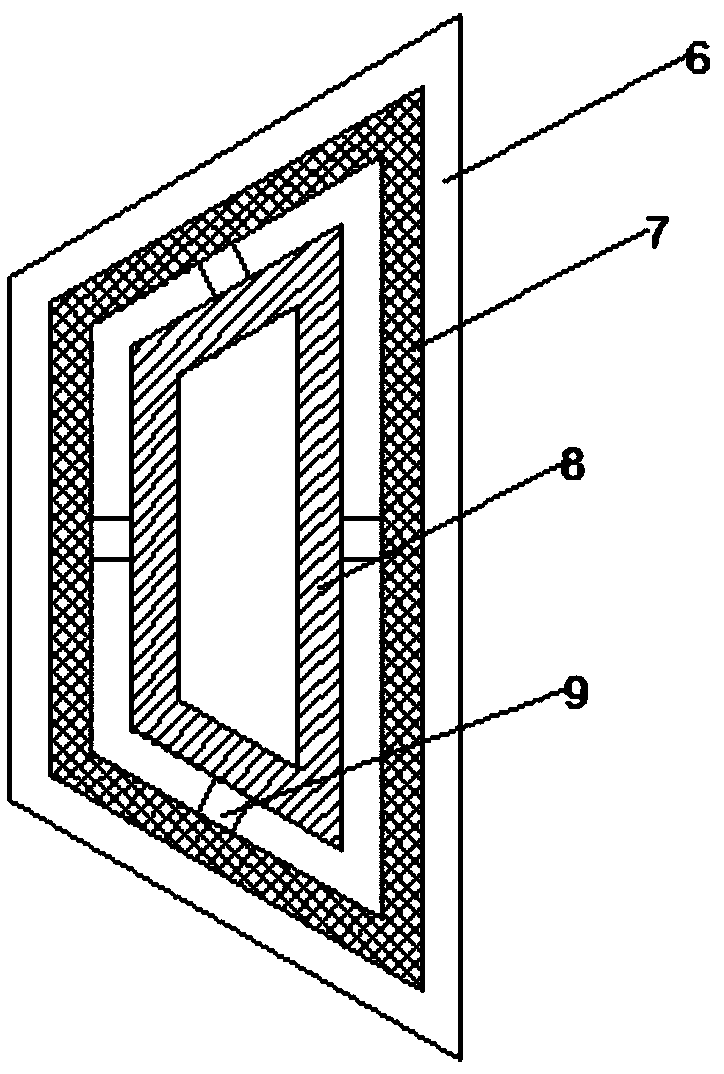

[0037] This embodiment discloses an amorphous alloy transformer, which includes an amorphous alloy iron core and a coil. The amorphous alloy iron core includes an iron core and a single-phase iron core cover. The iron core adopts a three-dimensional triangular iron core structure. It consists of three single-phase iron cores, and the single-phase iron cores are seamlessly connected; the single-phase iron cores include left and right iron core columns 1 and upper and lower iron yokes 12, forming a closed rectangular frame. The iron core cover is set outside the single-phase iron core; the left and right iron core columns 1 and the upper and lower iron yokes 12 are isosceles trapezoidal; The yoke pieces are superimposed, and the column piece and the yoke piece are both in the shape of an isosceles trapezoid. The extension lines of the waist of the column piece and the yoke piece pass through the center of the rectangular frame of the single-phase iron core, but the thickness of a...

Embodiment 2

[0040] This embodiment discloses an amorphous alloy low-loss transformer. The amorphous alloy low-loss transformer includes a coil and an iron core; the iron core adopts a three-dimensional triangular iron core structure, and the iron core includes an amorphous alloy strip; The chemical composition of the amorphous alloy strip is expressed in weight percent: Fe is 46wt%, Si is 9wt%, B is 4.5wt%, P is 8.5wt%, Co is 23wt%, Ni is 5wt%, and Zr is 4wt%. ; wherein iron and cobalt element weight percent is 2, silicon and boron element weight percent is 2.

[0041] This embodiment also discloses a method for preparing an amorphous alloy strip in an amorphous alloy low-loss transformer. The preparation method includes the following steps:

[0042] S1, Fe, Si, B, Co, P, Ni, Zr were respectively weighed in corresponding proportions, and added to the stirring device in turn for full stirring to obtain a mixture, the number of stirring times was 2, and the stirring time was 20 minutes;

...

Embodiment 3

[0049] The difference between this embodiment and the second and third embodiments is that the preparation method includes the following steps:

[0050] S1, Fe, Si, B, Co, P, Ni, Zr were respectively weighed in corresponding proportions, and added to the stirring device in turn for full stirring to obtain a mixture, the number of stirring times was 3 times, and the stirring time was 25 minutes;

[0051] S2, put the mixture into an electric arc melting furnace for the first melting, the vacuum degree is 0.03Pa, the melting temperature is 1700°C, and the melting time is 1.5h, to obtain alloy solution a;

[0052] S3, the alloy solution a is placed in a water cooling device to form an alloy ingot, and the circulating water pressure is set at 0.7MPa;

[0053] S4, put the alloy ingot into the electric arc melting furnace for the second melting, the vacuum degree is 0.08Pa, the melting temperature is 1950°C, and the melting time is 2.5h, to obtain the alloy solution b;

[0054] S5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com