COB mounting-based optical module circuit board and marking point design

A technology for marking points and circuit boards, applied in the field of optical communication, can solve the problems of high cost of coaxial sockets and caps, inability to guarantee placement accuracy and speed, and cost advantages, etc., to ensure integrity and reliability. Stability, improve accuracy and efficiency, avoid the effect of crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

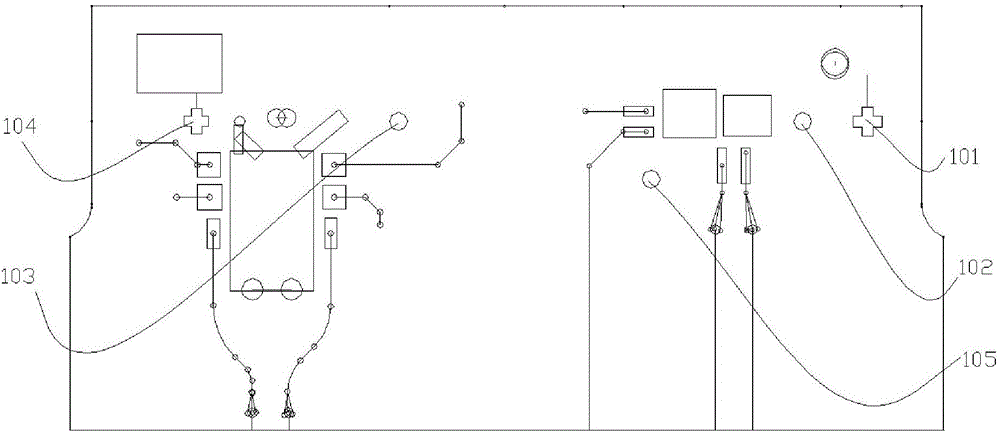

[0038] A design of optical module circuit board and marking points based on COB (CHIP ON BOARD) placement, including: finished circuit board and marking points;

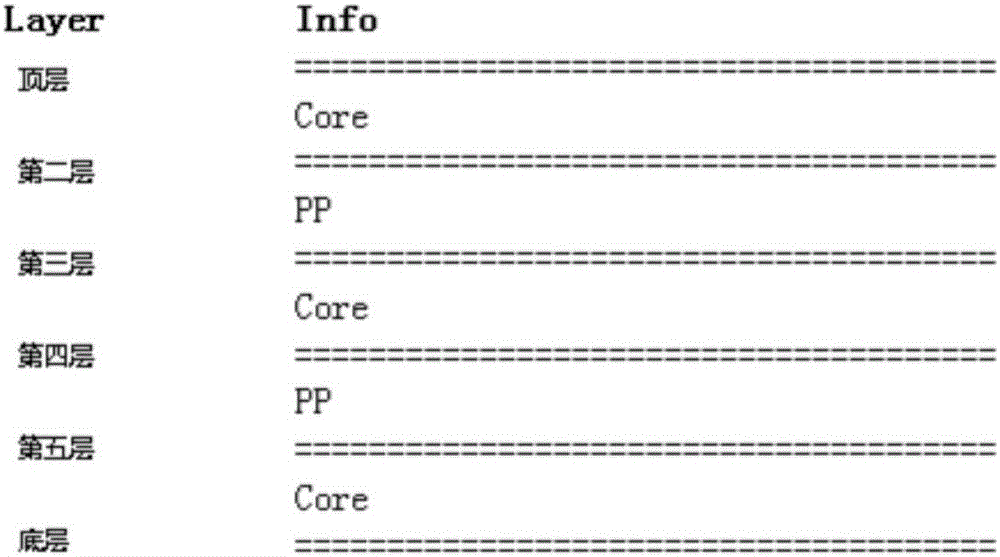

[0039] Pads can be placed on the finished circuit board, and the finished circuit board has six layers of boards, such as figure 2 As shown, from top to bottom are the top layer, the second layer, the third layer, the fourth layer, the fifth layer and the bottom layer;

[0040] The thickness of the finished circuit board is 0.9 mm to 1.1 mm, and the typical thickness of the circuit board is 1.0 mm; from top to bottom are the top layer, the second layer, the third layer, the fourth layer, the fifth layer and the bottom layer; the bottom layer The circuit board is convenient to design the power layer and the ground layer, avoiding crosstalk caused by the routing of the wiring layer, and ensuring the integrity and stability of the signal.

[0041] The finished circuit board has a certain degree of warpage, and the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com