A method of condensing and collecting uf6

A condenser and condensation separation technology, applied in the field of collecting UF6, can solve problems such as corrosion, and achieve the effect of avoiding scaling, prolonging working life and prolonging service life.

Active Publication Date: 2010-12-15

CNNC LANZHOU URANIUM ENRICHMENT

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Corrosion and perforation of the circulation pipe in the condenser, the general working life is only 120tU

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

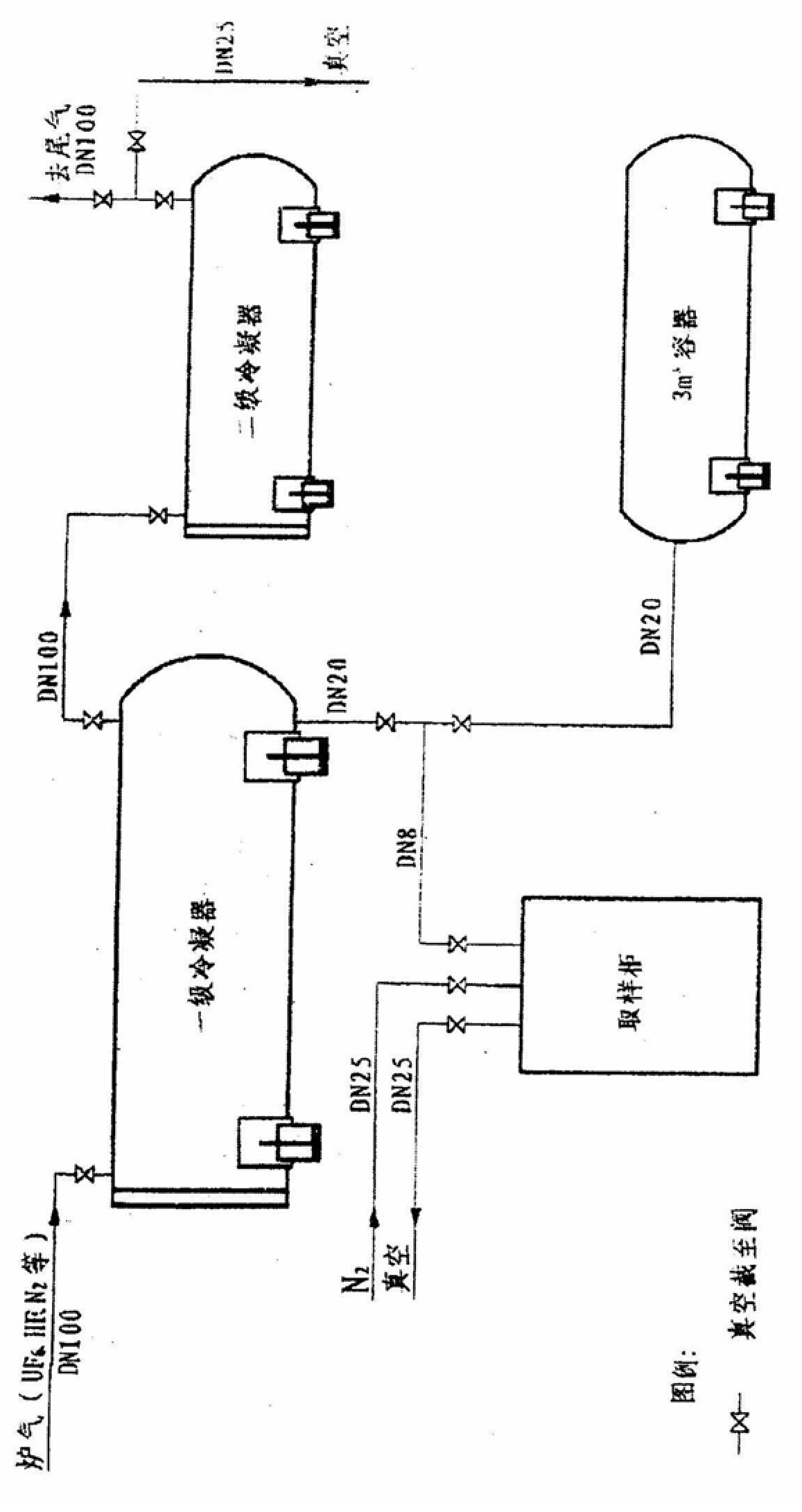

The invention belongs to a nuclear fuel preparation method, and specifically discloses a method for collecting UF6, which includes: inputting the UF6 gas mixture obtained by the gas-solid reaction of UF4 and F2 in a vertical fluorination furnace into a first-stage internal cooling and internal heating UF6 condenser, and passing through After condensing and separating most of the UF6, it is then input into the secondary internal cooling and internal heating UF6 condenser to condense and collect the remaining UF6, and the residual gas enters the exhaust gas treatment system to be purified and then emptied; among them, the refrigerant in the internal circulation pipe of the primary condenser is demineralized water , The temperature for receiving UF6 gas is 5-10°C. The present invention adopts demineralized water with low corrosion and no scaling as the secondary refrigerant of the first-stage internal cooling and internal heating type UF6 condenser, which reduces the corrosion of the internal circulation pipe of the internal cooling and internal heating type condenser; the temperature of the receiving gas is changed to 5-10 ℃, reduce the working temperature difference of the internal circulation pipe and reduce the stress corrosion of the internal circulation pipe. The working life of the condenser is extended to more than 1238tU, and the service life can reach more than 10 years; and the UF6 collection rate can still reach more than 99.6%.

Description

A condensate collection UF 6 Methods technical field The invention belongs to nuclear fuel preparation method, be specifically related to a kind of method of collecting UF6. Background technique UF6 is a kind of stable volatile gaseous uranium compound, and it is to make nuclear weapon uranium and nuclear power plant fuel element important raw materials. The preparation of UF6 generally adopts the gas-solid reaction of UF4 and F2 in a vertical fluorination furnace to obtain a UF6 gas mixture (including Including UF6, F2, HF, N2 and metal impurity fluoride gas, etc.), the UF6 gas mixture contains about 30-90% UF6, so The UF6 gas needs to be further collected from the UF6 gas mixture. The method of collecting UF6 gas in industry is condensation There are two methods of solid (referred to as condensation) and liquefaction. Condensation collection is the earliest and most widely used collection method. As follows: the UF6 gas mixture obtained by the gas-solid re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G43/06

Inventor 张习林王健康张改成王方太

Owner CNNC LANZHOU URANIUM ENRICHMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com