The method of converting the decommissioned compressor into a centrifugal pressure supplementary machine by using the diffusion method in the production of separated uranium isotopes

An isotope and compressor technology, which is applied in the field of separation of uranium, and achieves the effect of simple and easy reformation.

Active Publication Date: 2010-04-14

CNNC LANZHOU URANIUM ENRICHMENT

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If you buy a new pressurizer, there is no domestic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

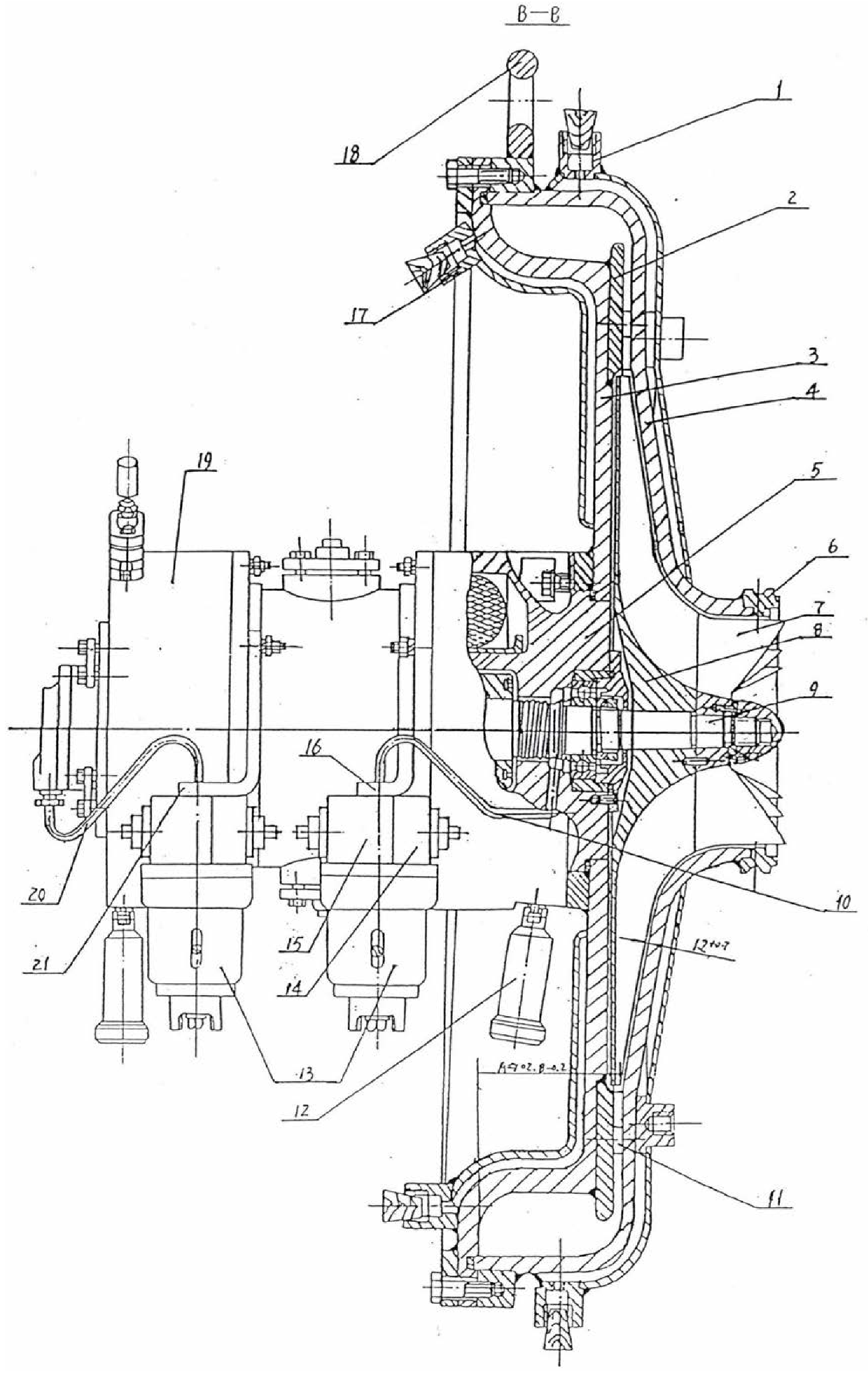

[0029] (2) Make a M10x17.5 screw hole at the center position of the inner shell 3 as the hanger hole of the inner shell 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

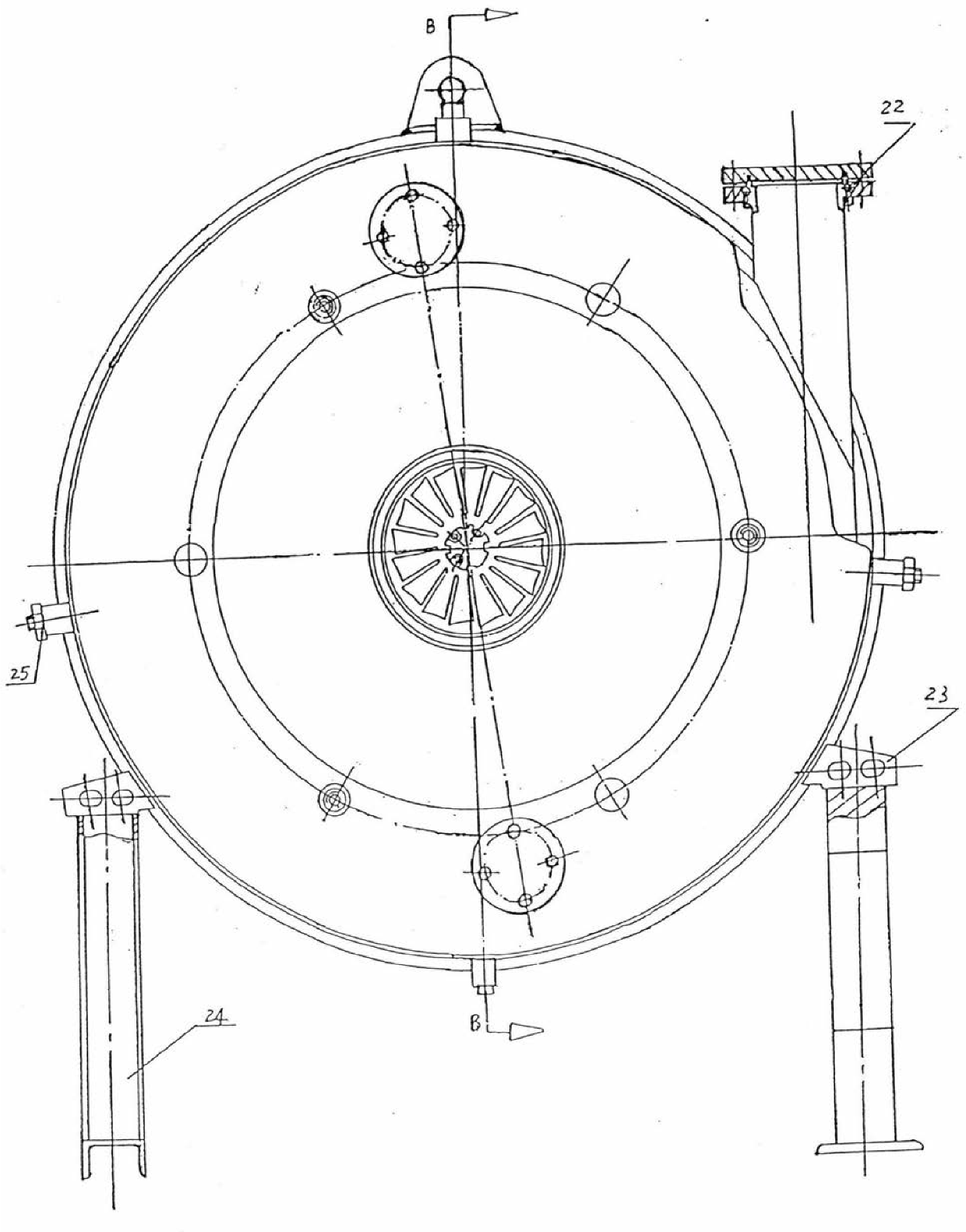

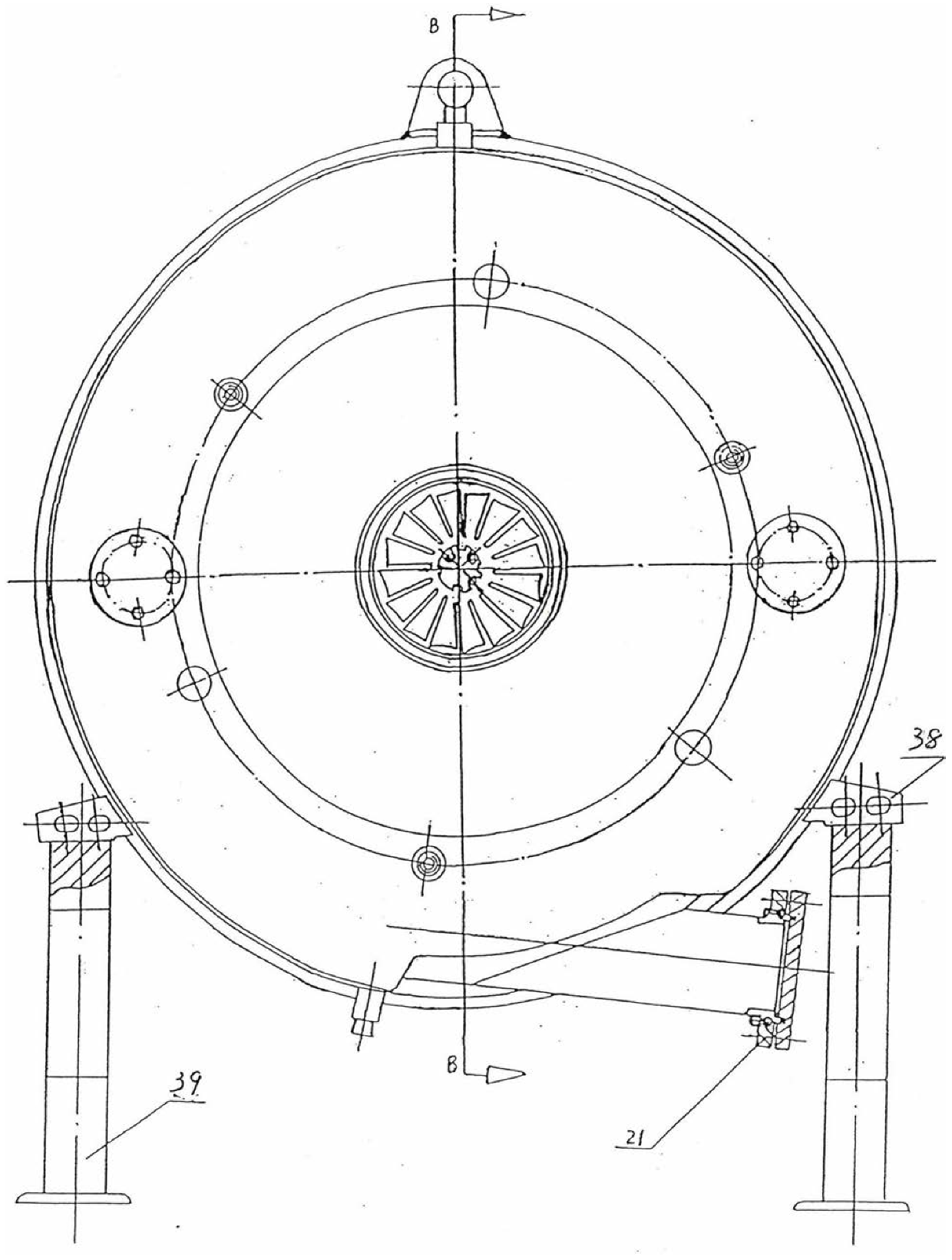

The invention relates to the construction of pressure supplement equipment for separating uranium isotopes by centrifugal method, in particular to a method for converting decommissioned compressors into centrifugal pressure supplement machines by using diffusion method. The decommissioned compressor for separation of uranium isotopes by diffusion method is removed from the diffuser vane to reduce the compression ratio, its internal and external structure and interface are modified to meet the requirements of the centrifugal process, and technical transformation methods such as replacing the bearing oiler are used to make it suitable for Section make-up presses and stream make-up presses in cascades for separation of uranium isotopes by centrifugation. After the reformation, the electromechanical test and the parameter measurement during the operation of the production system show that its main performance indicators have reached the design requirements and meet the requirements of the centrifugal cascade production process. Restructuring 100 units can save foreign exchange equivalent to 15 million yuan, and the method of reorganization is simple and easy.

Description

The method of converting decommissioned compressor into centrifugal pressure supplementary machine by diffusion method in the production of separated uranium isotope Technical field: The present invention relates to the construction of a kind of centrifugal separation uranium isotope pressurization equipment, be specifically related to a kind of In isotope production, the decommissioned compressor is transformed into a centrifugal pressure supplementing machine by diffusion method. Background technique: At present, be used for the pressurization and delivery of uranium hexafluoride (UF6) diffusion gas in the uranium isotope production technique of diffusion The delivery compressor, namely the OK-19 compressor, was imported from the former Soviet Union in the 1950s. In my country, with the separation of uranium isotopes With the development of production technology, the diffusion method is being replaced by the centrifugal method. The original OK-19 compressor has a hi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04D17/10F04D17/12F04D29/00

Inventor 谭保成朱根林张敏谦宋健孙芳

Owner CNNC LANZHOU URANIUM ENRICHMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com