A servo system control cable assembly

A technology for controlling cables and servo systems, applied in electrical components, communication cables, cables, etc., can solve problems such as difficulty in ensuring the tightness of the servo system, and achieve the effect of the reliability of the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

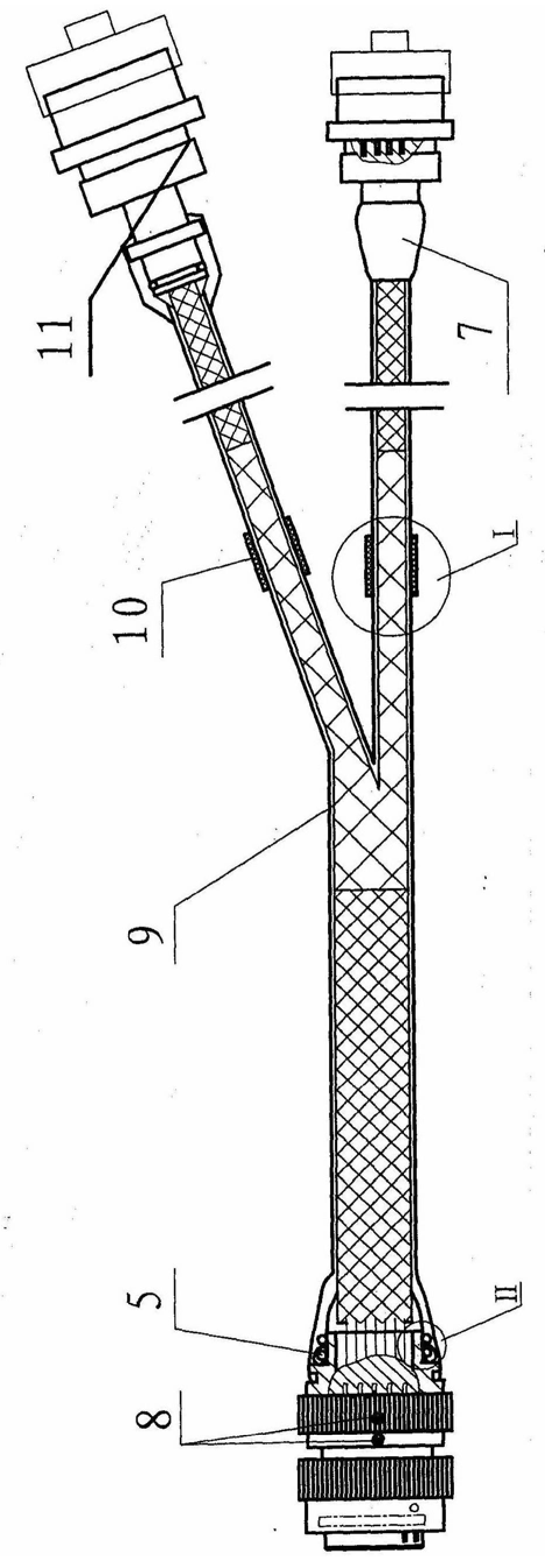

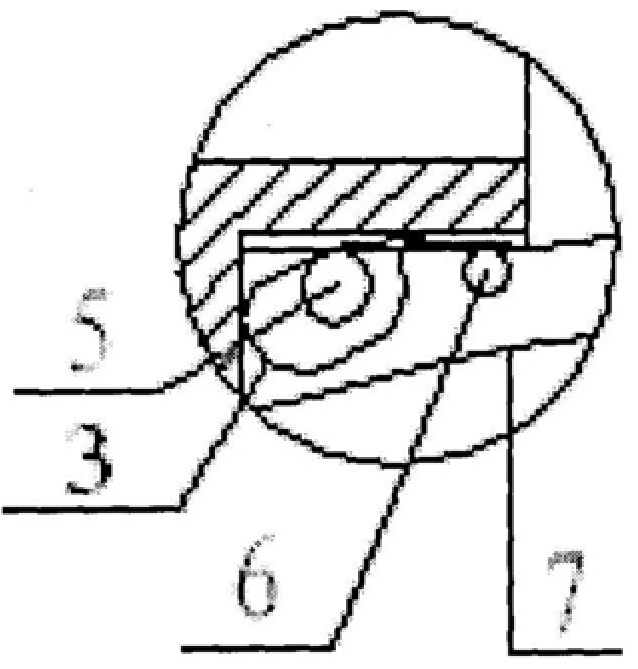

[0016] The servo system control cable assembly of the present invention will be further described below with reference to the drawings and specific embodiments.

[0017] As shown in FIG. 1, the servo system control cable assembly of the present invention mainly includes a high temperature wire 1, an outer layer heat shrinkable tube

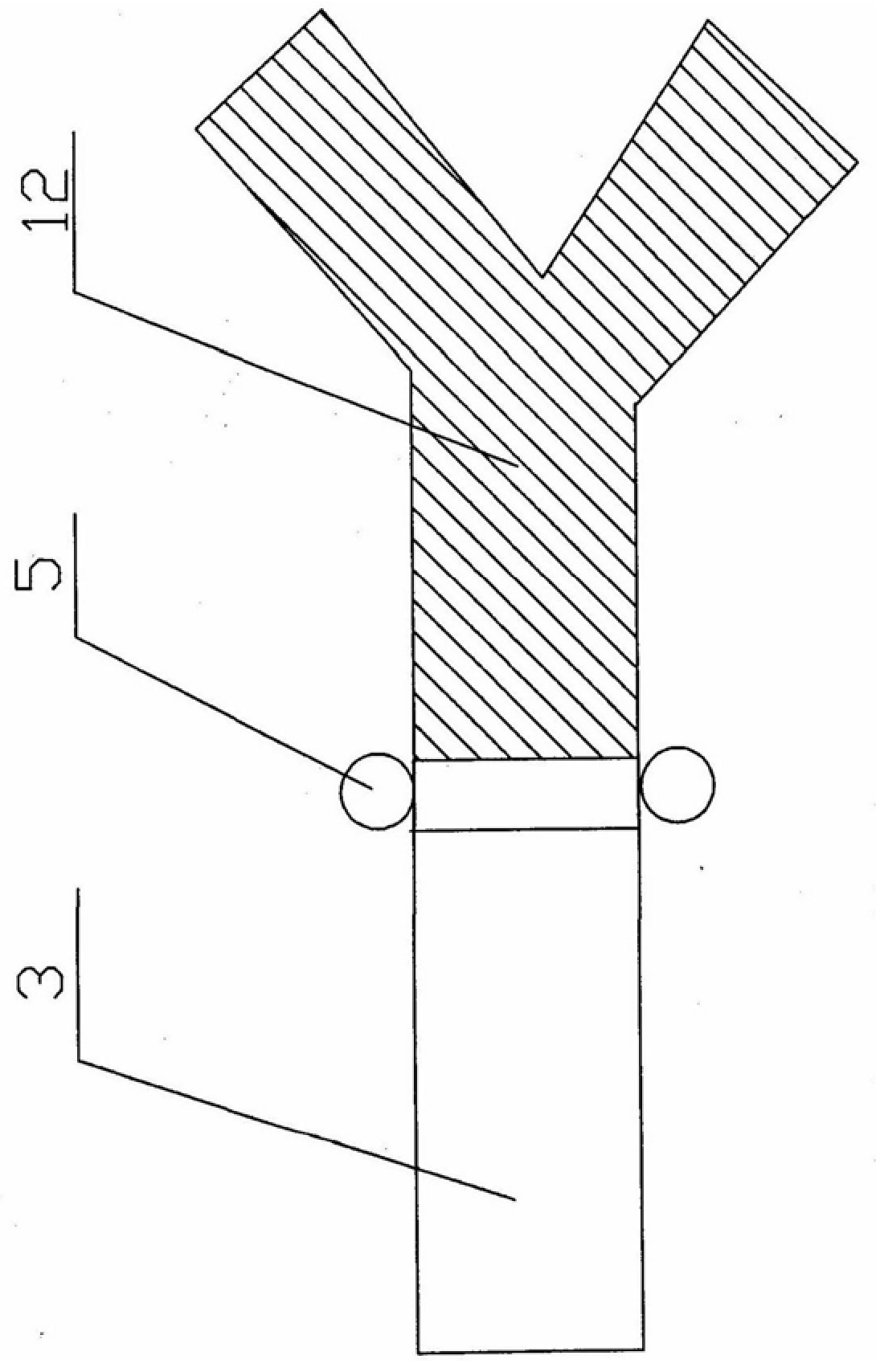

[0018] As shown in Figure 3, the heat-shrinkable bifurcated cable assembly is a high-temperature wire from the inside to the outside, a white soft inner layer heat-shrinkable

[0019] High temperature cable wires-electrical connection with electrical components of the control socket and product.

[0020] Inner layer heat shrink tube-high temperature heat shrink is used to fasten the cable bundle and prevent the wave shield from breaking the cable. Optional anti

[0021] Anti-wave sleeve-used for cable shielding, high reliability to achieve continuous shielding.

[0022] Outer layer heat shrink tube-used for heat shrink fastening, high temperature environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com