MEMS (Micro-Electro-Mechanical System) device, manufacturing method thereof and electronic device

A technology for electronic devices and MEMS patterns, which is applied in the manufacture of microstructure devices, microstructure devices, semiconductor/solid-state device components, etc., can solve problems such as fragmentation, easy breakage, and wafer fragility, so as to reduce process costs and increase service life , the effect of reducing the probability of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

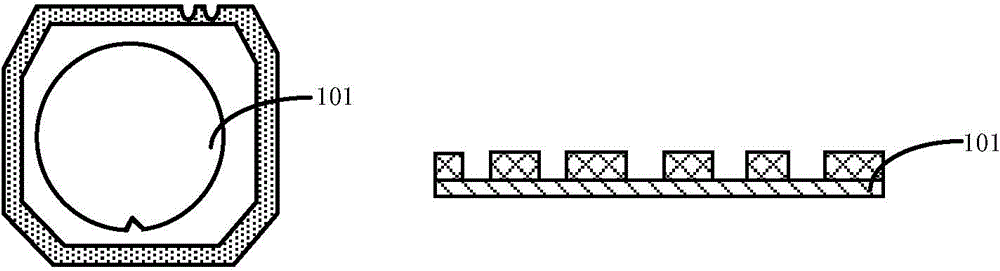

[0039] Because deep etching is often used in the preparation process of MEMS devices, there are many deep grooves in the MEMS wafer, such as Figure 1a As shown in the figure on the right, some products are very thin, which makes the wafer very fragile and easy to break, such as Figure 1d The position indicated by the arrow. The problem of fragmentation will occur when doing the WaferMount process of such MEMS products.

[0040]Therefore, it is necessary to further improve the cutting method of the current MEMS wafer in order to eliminate the above-mentioned problems.

Embodiment 1

[0042] In order to solve the problems existing in the prior art, the present invention provides a kind of preparation method of MEMS device, below in conjunction with attached Figure 2a-2d The method is described further.

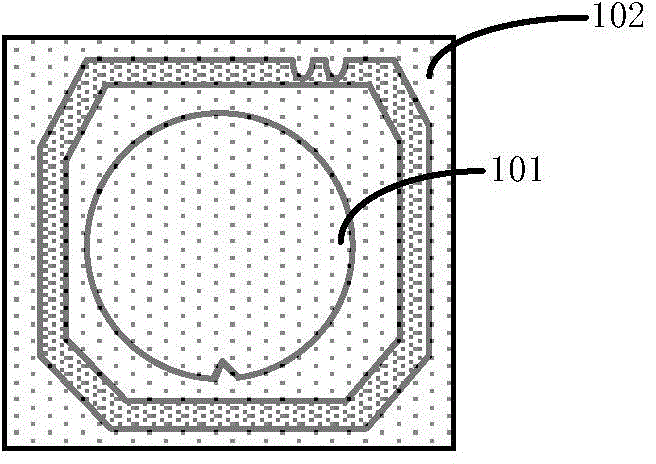

[0043] First, step 201 is performed to provide a MEMS wafer 201 on which MEMS patterns are formed.

[0044] Specifically, such as Figure 2a As shown, the MEMS wafer 201 can be made of semiconductor materials such as silicon, polysilicon or SiGe, and is not limited to a certain one.

[0045] The MEMS device formed in the present invention may be a sensor, such as a pressure sensor, an acceleration sensor, etc., or a MEMS microphone, or other types of MEMS devices, and is not limited to a certain one.

[0046] Wherein, the MEMS pattern includes deep holes and / or deep grooves, such as Figure 2a As shown in the figure on the right, the pattern is not limited to this example, and other patterns may be formed.

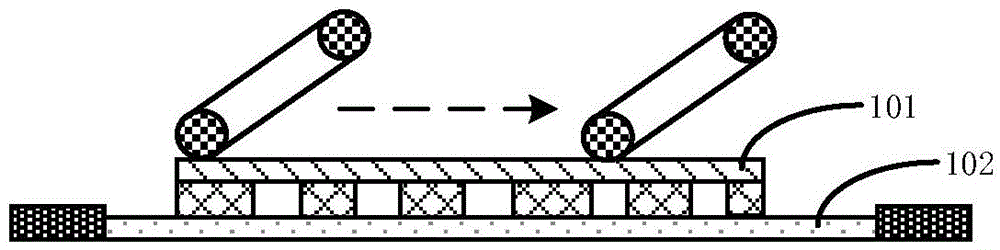

[0047] Then the MEMS wafer 201 forming the M...

Embodiment 2

[0067] In order to solve the problems existing in the prior art, the present invention provides a kind of preparation method of MEMS device, below in conjunction with attached Figures 3a-3d The method is described further.

[0068] First, step 301 is performed to provide a MEMS wafer 301 on which MEMS patterns are formed.

[0069] Specifically, such as Figure 3a As shown, the MEMS wafer 301 can be made of semiconductor materials such as silicon, polysilicon or SiGe, and is not limited to a certain one.

[0070] The MEMS device formed in the present invention may be a sensor, such as a pressure sensor, an acceleration sensor, etc., or a MEMS microphone, or other types of MEMS devices, and is not limited to a certain one.

[0071] Wherein, the MEMS pattern includes deep holes and / or deep grooves, such as Figure 3a As shown in the figure on the right, the pattern is not limited to this example, and other patterns may be formed.

[0072] Then the MEMS wafer 301 forming the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com