Fermented oat beverage and preparation method thereof

A technology for oats and beverages, applied in the directions of bacteria, food ingredients, and functions of food ingredients used in food preparation, can solve problems such as limited nutrition and health care functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

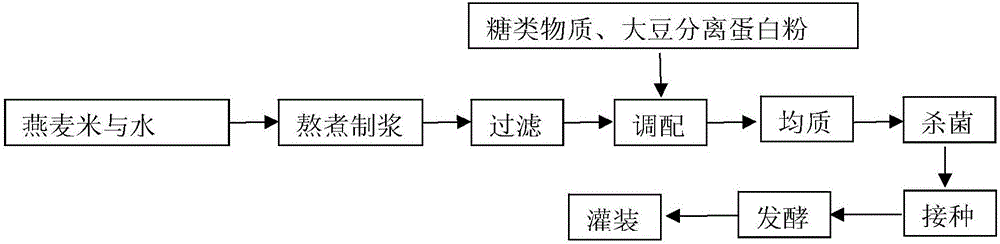

[0030] The present invention also provides a preparation method of oat fermented drink, comprising the following steps:

[0031] A) mixing the oatmeal and water, followed by boiling, refining and filtering, to obtain the oat filtrate;

[0032] B) mixing the sugar substance with the oat filtrate, followed by homogenization and sterilization, to obtain a feed liquid;

[0033] C) Lactobacillus casei zhang, Lactobacillus plantarum P-8 and Bifidobacterium V9 were inoculated into the feed liquid for fermentation, and after the fermentation was completed, an oat fermented beverage was obtained.

[0034] combine figure 1 The preparation method of the oat fermented drink provided by the invention is described in detail, figure 1 The process flow chart for the preparation of the oat fermented drink provided by the present invention.

[0035] In the present invention, oatmeal and water are firstly mixed, followed by boiling, refining and filtering in order to obtain oat filtrate;

[...

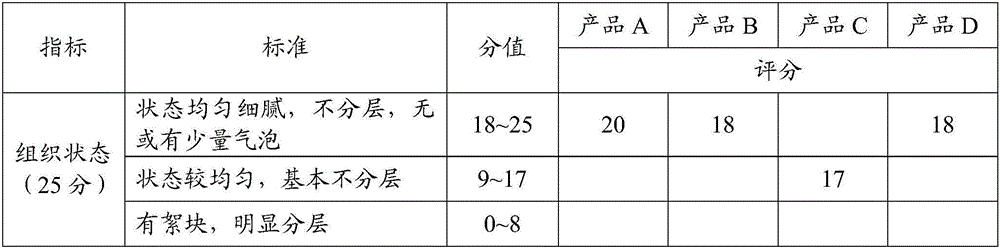

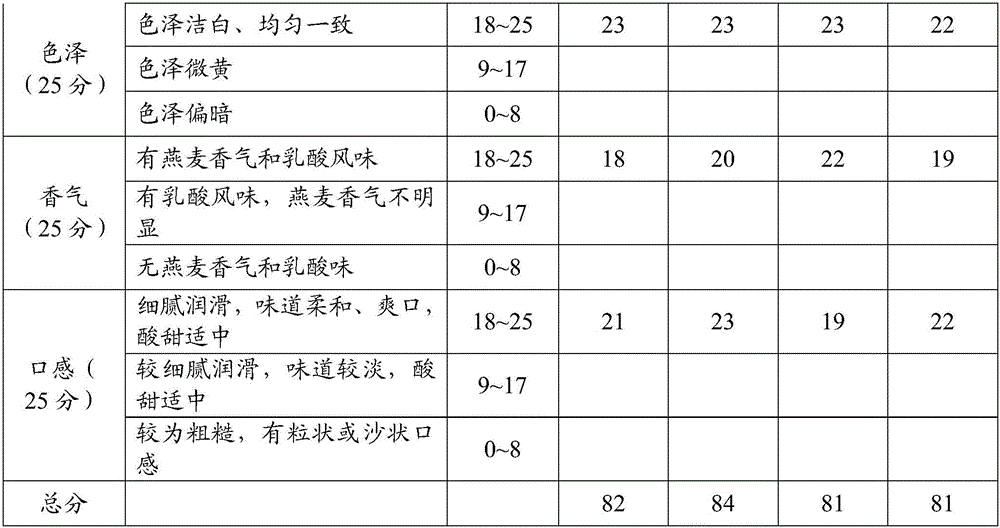

Embodiment 1

[0056] Add oatmeal into water, the amount of oatmeal added accounts for 3% of the weight of the water; boil for 90 minutes, and filter the slurry after refining through a 120-mesh sieve to obtain oat filtrate; Granulated sugar is mixed and prepared; the mixed material liquid is subjected to secondary homogenization, the homogenization pressure is 35MPa, and the homogenization temperature is 55°C; sterilized at 85°C for 15min; Lactobacillus plantarum P-8 and Bifidobacterium V9 were mixed in a ratio of 1:1.7:1.1 (wherein the strain vigor of each starter bacterial powder was respectively: Lactobacillus casei zhang was 7.5×10 11 CFU / g, Lactobacillus plantarum P-8 is 3×10 11 CFU / g, Bifidobacterium V9 is 4.5×10 11 CFU / g), the total inoculum size is 0.6×10 7 CFU / mL was added to the lactic acid bacteria mixed starter; the inoculated feed liquid was fermented at a constant temperature of 35°C, and when the pH value reached 3.8, it was immediately cooled to below 5°C to stop fermentat...

Embodiment 2

[0058] Add oatmeal into water, the amount of oatmeal added accounts for 3.7% of the weight of water; boil for 105min, and the slurry after refining is filtered through a 120-mesh sieve to obtain oat filtrate; Granulated sugar was mixed and prepared; the mixture liquid was homogenized twice, the homogenization pressure was 40MPa, and the homogenization temperature was 60°C; sterilized at 90°C for 10 minutes; the sterilized feed liquid was rapidly cooled to 37°C; Lactobacillus casei zhang, Lactobacillus plantarum P-8 and Bifidobacterium V9 were mixed in a ratio of 1:3.8:2.5 (wherein the bacterial strain vigor of each starter bacterial powder was respectively: Lactobacillus casei zhang was 7.5×10 11 CFU / g, Lactobacillus plantarum P-8 is 2×10 11 CFU / g, Bifidobacterium V9 is 3×10 11 CFU / g), the total inoculum size is 1.0×10 7 CFU / mL was added to the lactic acid bacteria mixed starter; the inoculated feed liquid was fermented at a constant temperature of 37°C, and when the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com