Preserved pumpkin and preparation method thereof

A technology of preserved pumpkin and sliced pumpkin, which is applied in confectionary, confectionary industry, food science, etc., can solve the problem of single eating method, and achieve the effect of simple preparation method, less food additives, and guaranteed color and fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

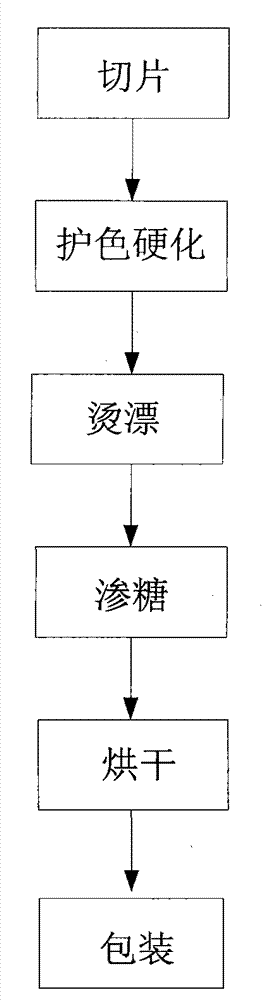

[0026] The invention provides a preparation method of preserved pumpkin, comprising the following operations: (1) slicing: cutting the pumpkin that has been cleaned, peeled and fleshed into slices with a thickness of 6-8mm; (2) color protection and hardening: Soak the pumpkin slices in a solution containing a color-protecting agent and a hardening agent for 8-16 hours; (3) blanching: heat the pumpkin slices that have completed the color-protecting and hardening at 90-100°C for 3-5 minutes; (4) infiltrate Sugar: Cool the blanched pumpkin slices to 30-40°C and soak them for 48-72 hours in a sugar solution with a sweetener mass fraction of 35%-50%; Drain the sugar liquid on the surface of the pumpkin slices, and then dry them at 45-60°C for 5-7 hours, and then dry them at 80-85°C for 2-3 hours; (6) Packaging: the dried pumpkin slices are shaped and packaged .

[0027] In order to prepare preserved pumpkins, first select pumpkins that are free from mildew and deterioration, and a...

Embodiment 1

[0036]Select the pumpkin, pick out the rot, deterioration and sundries left in the pumpkin, clean the dirt such as mud and sand on the pumpkin, and then peel the skin. Cut the peeled pumpkin in half and remove the pulp. Afterwards, the pumpkin that has been removed is cut into 6-8mm thick pumpkin slices, and the length of the pumpkin slices is generally cut into 7-10cm. Soak the pumpkin slices in a solution with a mass fraction of 0.3‰ of sodium chloride, 0.2‰ of sodium metabisulfite, and 0.5‰ of calcium chloride for 16 hours to protect the color and harden the pumpkin slices. After the color protection and hardening are completed, the pumpkin slices are placed in a jacketed pot and heated for 3-5 minutes at a heating temperature of 90-100°C. The heated pumpkin slices were cooled to 30°C, and then soaked in a sugar solution with a mass fraction of 35% sweetener for 72 hours to further increase the sugar content in the pumpkin slices, wherein the sweeteners used were white gra...

Embodiment 2

[0038] Select the pumpkin, pick out the rot, deterioration and sundries left in the pumpkin, clean the dirt such as mud and sand on the pumpkin, and then peel the skin. Cut the peeled pumpkin in half and remove the pulp. Afterwards, the pumpkin that has been removed is cut into 6-8mm thick pumpkin slices, and the length of the pumpkin slices is generally cut into 7-10cm. Soak the pumpkin slices in a solution with a mass fraction of 0.4‰ of sodium chloride, 0.2‰ of sodium metabisulfite, and 0.4‰ of calcium chloride for 12 hours to protect the color and harden the pumpkin slices. After the color protection and hardening are completed, the pumpkin slices are placed in a jacketed pot and heated for 3-5 minutes at a heating temperature of 90-100°C. Cool the heated pumpkin slices to 35°C, and then soak them in a sugar solution with a mass fraction of 40% sweetener for 60 hours to further increase the sugar content in the pumpkin slices, wherein the sweetener used is fructose syrup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com