Needle inserting positioner for patellar fracture

A patella fracture and locator technology, applied in the field of fracture needle locator and patella fracture needle locator, can solve problems such as unstable fixation, limited needle insertion angle, direction, trauma, etc., to increase the success rate of surgery , Simple operation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

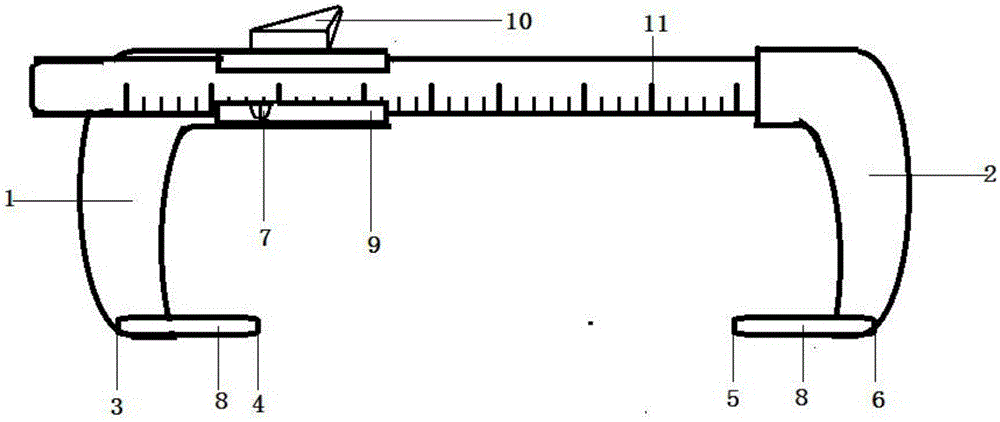

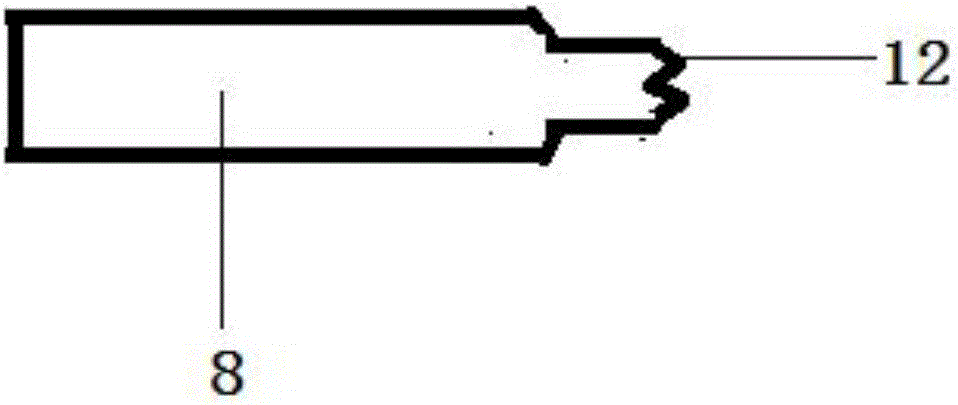

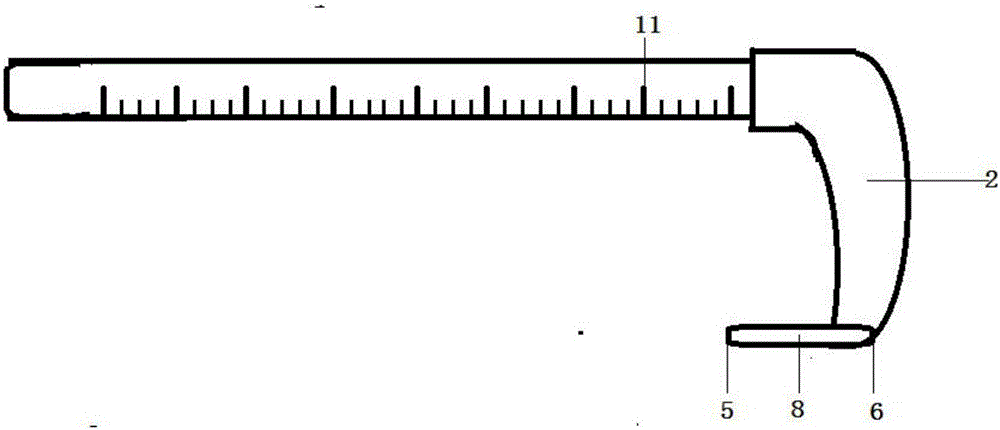

[0041] Such as figure 1 , 2 , 3, 4, and 9 show a needle positioning device for patella fractures, including two "L"-shaped positioning pieces, which are respectively A piece 1 and B piece 2, and the A piece 1 and B piece 2 Combined to form a "C"-shaped structure, one end of the A piece 1 and B piece 2 is provided with opposite fixed teeth 8, the A piece 1 is provided with a limiting groove 9, and the A piece 1 and B piece 2 are connected A buckle 10 is provided at the position; the fixed teeth 8 contain developing materials under X-ray.

[0042] The lock is a one-way anti-backward lock. After A piece and B piece are combined with each other, when sliding B piece in the limit groove moves along the direction of reducing the distance between the two fixed teeth, the lock buckle does not stop, and A piece and B piece move freely. When the relative movement stops, the buckle is automatically locked, and the AB pieces cannot move with each other. When it is necessary to move th...

Embodiment 2

[0053] Such as figure 1 , 2 , 3, 4, and 9 show a needle positioning device for patella fractures, including two "L"-shaped positioning pieces, which are respectively A piece 1 and B piece 2, and the A piece 1 and B piece 2 Combined to form a "C"-shaped structure, one end of the A piece 1 and B piece 2 is provided with opposite fixed teeth 8, the A piece 1 is provided with a limiting groove 9, and the A piece 1 and B piece 2 are connected A buckle 10 is provided at the position; the fixed teeth 8 contain developing material under X-ray.

[0054] The lock is a one-way anti-backward lock. After the A piece and the B piece are combined with each other, when the sliding piece B moves in the limiting groove along the direction of decreasing the distance between the two fixed teeth, the lock buckle does not stop, and the A piece and the B piece move freely. When the relative movement stops, the buckle is automatically locked, and the AB pieces cannot move with each other. When it...

Embodiment 3

[0067] In vitro simulation experiment of a needle positioning device for patella fracture

[0068] Objective: To explore whether the needle locator for patella fracture can improve the accuracy of needle placement by making a patella fracture model in vitro;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com