Processing method of honeysuckle flowers

A processing method, the technology of honeysuckle, applied in the direction of pharmaceutical formula, plant raw materials, plant/algae/fungus/moss components, etc., can solve the problem of large period of honeysuckle, and achieve the effect of preventing flowering or even withering, inhibiting activity, and preventing blooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Technical scheme of the present invention is: honeysuckle processing method, comprises the following steps:

[0034] The first step is picking. Pick the bluish-white, swollen upper part and stick-shaped honeysuckle flower buds from 9 to 12 in the morning, and put the picked honeysuckle in the bamboo basket;

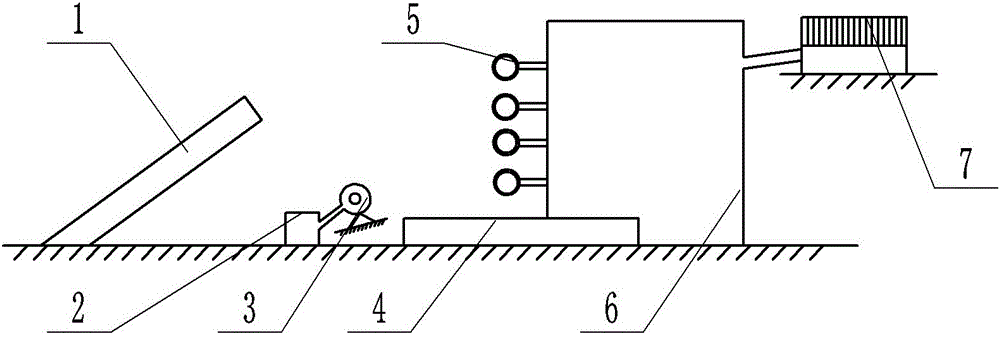

[0035] The second step is to set the water removal device. The water removal device includes on the first conveyor belt. The angle between the first conveyor belt and the horizontal plane is 20°. A fan is installed below the fan, the angle between the outlet of the fan and the horizontal plane is 30°, the outlet temperature of the fan is 10°C, and the wind rate of the fan is 1100m3 / h. Shaped charcoal, the collection device is connected to the fan through the air pipe, and a valve is set at the joint between the air pipe and the collection device;

[0036] The third step is deoxygenation treatment, the charcoal in the collection device is ignited, and the charcoal ...

Embodiment 2

[0047] The difference with Example 1 is: the processing data is the data of Example 2 in Table 1, the angle between the first conveyor belt and the horizontal plane is 30°, the angle between the air outlet and the horizontal plane is 40°, and the charcoal burning time is 7min , the temperature in the storage room is 11°C, the finishing temperature is 90°C, the finishing pressure is 0.035Mpa, the finishing time is 2min, the cooling time is 50s, the drying temperature is 70°C, the drying pressure is 0.04Mpa, and the drying time is 2.5h , the air outlet temperature of the fan is 14°C, the wind rate is 1300m3 / h, and the conveying rate is 0.05m / s.

Embodiment 3

[0049] The difference with Example 1 is: the processing data is the data of Example 3 in Table 1, the angle between the first conveyor belt and the horizontal plane is 40°, the angle between the air outlet and the horizontal plane is 50°, and the charcoal burning time is 10min , the temperature in the storage room is 16°C, the finishing temperature is 100°C, the finishing pressure is 0.04Mpa, the finishing time is 3min, the cooling time is 70s, the drying temperature is 90°C, the drying pressure is 0.05Mpa, and the drying time is 3h. The air outlet temperature of the fan is 18°C, the wind rate is 1500m3 / h, and the conveying rate is 0.08m / s.

[0050] The following is the degree of oxidation of this honeysuckle during processing:

[0051] Choose 4 frames of honeysuckle just plucked, each frame of honeysuckle is 200 plants, wherein 3 frames of honeysuckle are processed according to the method of embodiment 1, embodiment 2 and embodiment 3 respectively as the experimental group, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com