A kind of 4-amino-2-hydroxybenzoic acid sodium synergistic polysiloxane defoamer

A technology of sodium hydroxybenzoate and phenylmethyl polysiloxane, which is applied in the direction of foam dispersion/prevention, chemical instruments and methods, liquid degassing, etc., and can solve the problem of large amount of polysiloxanes used and raw material components Complicated problems, to achieve low cost, high economic and ecological benefits, and improve high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

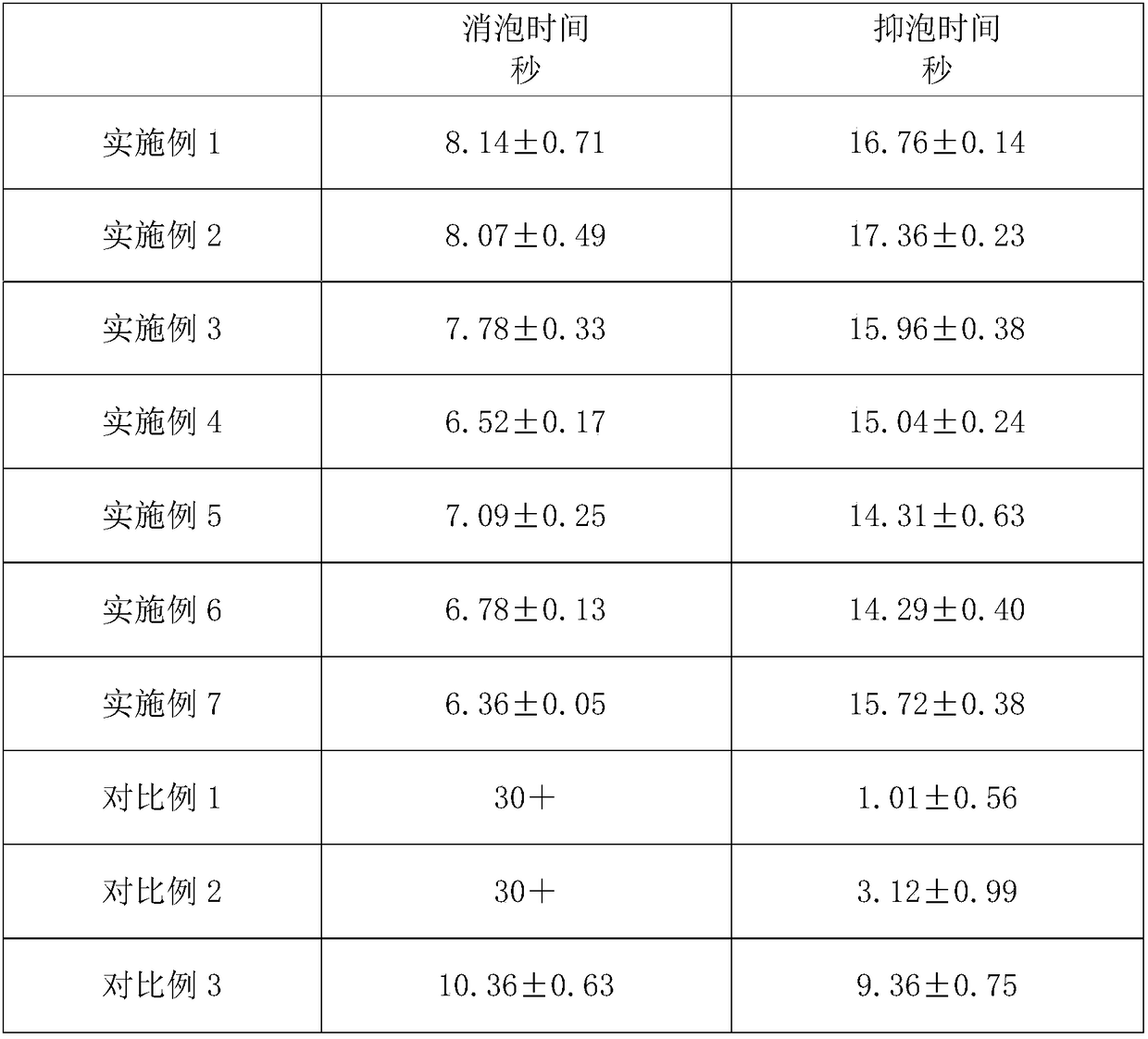

Examples

Embodiment 1

[0028] A 4-amino-2-hydroxybenzoate sodium synergistic polysiloxane defoamer, based on a total of 100 parts by weight, consists of the following parts by weight:

[0029] Polyborosiloxane: 0.1 part; Sodium 4-amino-2-hydroxybenzoate: 0.01 part;

[0030] Phenylmethyl polysiloxane: 0.6 parts; 4-methyl-2-hexanol: 10 parts;

[0031] Water: balance.

[0032] The preparation method of described defoamer is:

[0033] Add sodium 4-amino-2-hydroxybenzoate and higher aliphatic alcohol to a part of the solvent, heat up to 40°C, heat and stir for 1 minute;

[0034] Then slowly add polyborosiloxane under stirring, heat up to 60°C and then keep stirring for 3 minutes;

[0035] Continue to slowly add phenylmethyl polysiloxane under stirring, heat up to 70°C, and keep stirring for 10 minutes;

[0036] Finally, add the remaining solvent and stir slowly and cool down to room temperature to obtain a defoamer.

Embodiment 2

[0038] A 4-amino-2-hydroxybenzoate sodium synergistic polysiloxane defoamer, based on a total of 100 parts by weight, consists of the following parts by weight:

[0039] Polyborosiloxane: 1 part; Sodium 4-amino-2-hydroxybenzoate: 10 parts;

[0040] Phenylmethyl polysiloxane: 1 part; 3-heptanol: 10 parts;

[0041] Isomerized tridecanol: 15 parts; water: balance.

[0042] The preparation method of described defoamer is:

[0043] Add sodium 4-amino-2-hydroxybenzoate and higher aliphatic alcohol to a part of the solvent, heat up to 50°C, heat and stir for 2 minutes;

[0044] Then slowly add polyborosiloxane under the action of stirring, heat up to 65°C, and then heat and stir for 5 minutes;

[0045] Continue to slowly add phenylmethylpolysiloxane under stirring, heat up to 75°C, and keep stirring for 20 minutes;

[0046] Finally, add the remaining solvent and stir slowly and cool down to room temperature to obtain a defoamer.

Embodiment 3

[0048] A 4-amino-2-hydroxybenzoate sodium synergistic polysiloxane defoamer, based on a total of 100 parts by weight, consists of the following parts by weight:

[0049] Polyborosiloxane: 0.2 part; Sodium 4-amino-2-hydroxybenzoate: 1 part;

[0050] Phenylmethyl polysiloxane: 0.6 parts; 4-methyl-2-hexanol: 5 parts;

[0051] 3-heptanol: 5 parts; isomeric tridecanol: 5 parts; 2-hexyldecanol: 5 parts;

[0052] Myristyl alcohol: 5 parts; water: the balance.

[0053] The preparation method of described defoamer is:

[0054] Add sodium 4-amino-2-hydroxybenzoate and higher aliphatic alcohol to a part of the solvent, heat up to 40°C, heat and stir for 1 minute;

[0055] Then slowly add polyborosiloxane under stirring, heat up to 60°C and then keep stirring for 3 minutes;

[0056] Continue to slowly add phenylmethyl polysiloxane under stirring, heat up to 75°C, and keep stirring for 10 minutes;

[0057] Finally, add the remaining solvent and stir slowly and cool down to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com