Pressurizing device for conduction oil lubricating grease

A pressurizing device and heat-conducting oil technology, applied in mixers with rotating stirring devices, transportation, packaging, dissolution, etc., can solve the problems of low heating efficiency, inconvenient operation, unfavorable use, etc., and achieve high working efficiency and responsiveness Short time, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

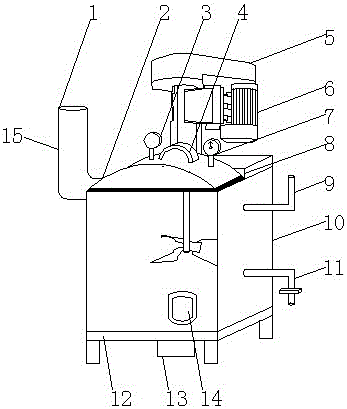

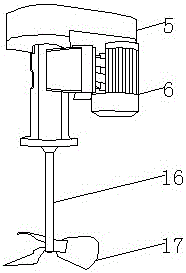

[0014] The technical solution of the present invention is described in detail in conjunction with the accompanying drawings, a heat transfer oil grease pressurization device, including a flip cover 2, a reducer 5, a motor 6, a kettle 10, a heating device 13, and a heat transfer oil pipe 15, between the kettle 10 and the flip cover 2 It is connected through the connecting hinge rotation, and the handle 4 is installed on the flip cover 2, and the pressure relief valve 3 and the pressure gauge 7 are installed on both sides of the handle 4 in turn, and the base one 8 is installed on the rear position of the flip cover 2, and the base one 8 A motor 6 is installed, and the driving wheel of the motor 6 and the driven wheel of the reducer 5 are connected in rotation through a transmission belt, and the motor 6 and the planetary agitator 17 arranged in the kettle 10 are connected through a transmission rod 16. One side of 10 is equipped with heat-conducting oil pipe 15, still 10 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com