High-frequency high-voltage arc ignition circuit

An arc ignition circuit, high frequency and high voltage technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as low success rate of arc ignition, high transformer cost, and affecting device life, etc., and achieve simple circuit connection Easy to understand, high success rate of arc starting, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

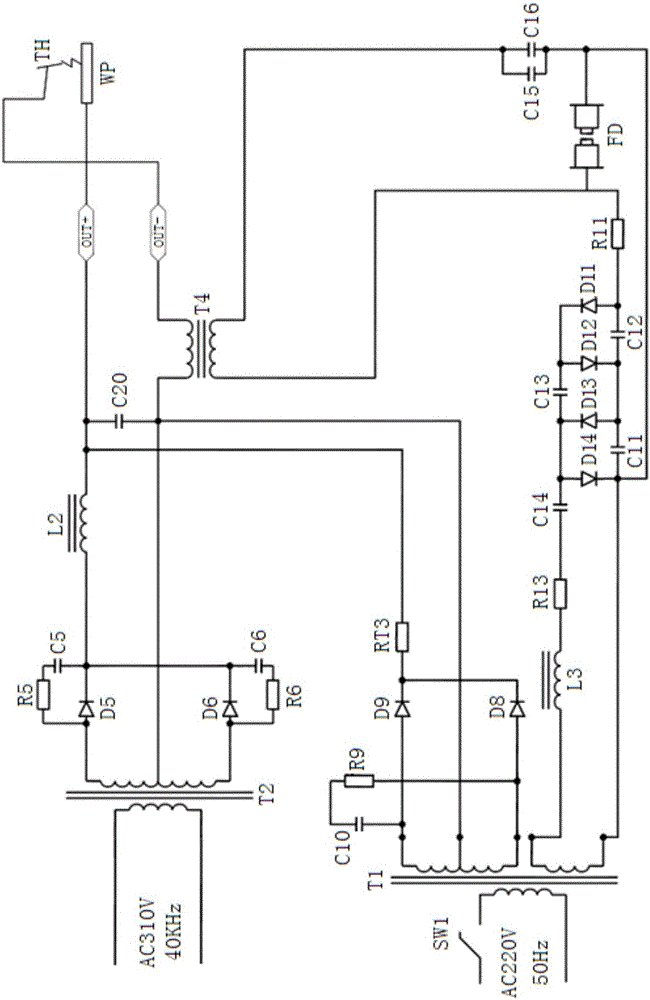

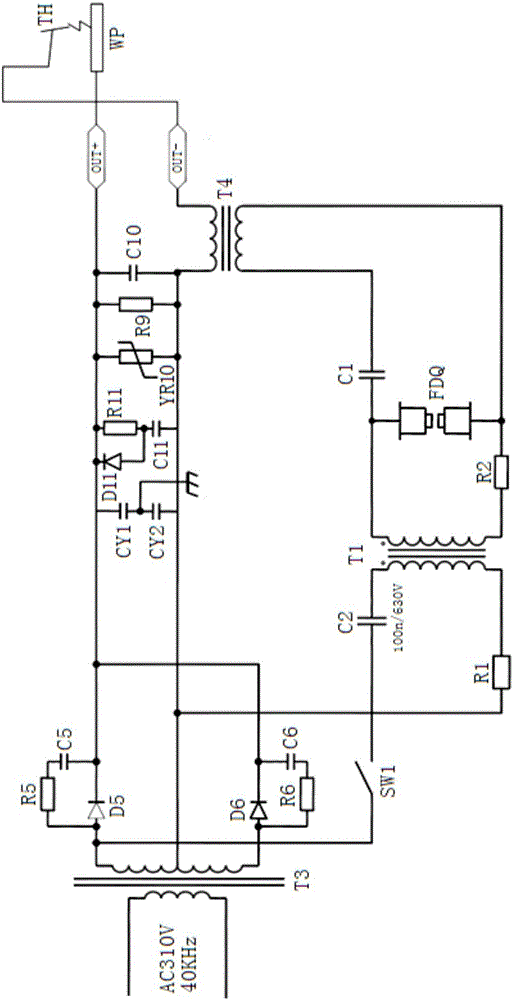

[0016] refer to Figure 1-2 , this specific embodiment adopts the following technical solutions: a high-frequency high-voltage arc ignition circuit, including a high-frequency step-up transformer T1, a main transformer T3, a high-frequency coupling transformer T4, a switch SW1, a high-frequency arc ignition device FDQ, a first capacitor C1, The second capacitor C2, the fifth capacitor C5, the sixth capacitor C6, the tenth capacitor C10, the eleventh capacitor C11, the first bypass capacitor CY1, the second bypass capacitor CY2, the first resistor R1, the second resistor R2, Fifth resistor R5, sixth resistor R6, ninth resistor R9, eleventh resistor R11, varistor YR10, fifth diode D5, sixth diode D6, eleventh diode D11; main transformer The primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com