Flexible laser machining system

A flexible processing and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of heavy manual workload, cumbersome operation, and unfavorable production and processing efficiency, so as to improve the degree of automation and achieve continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings.

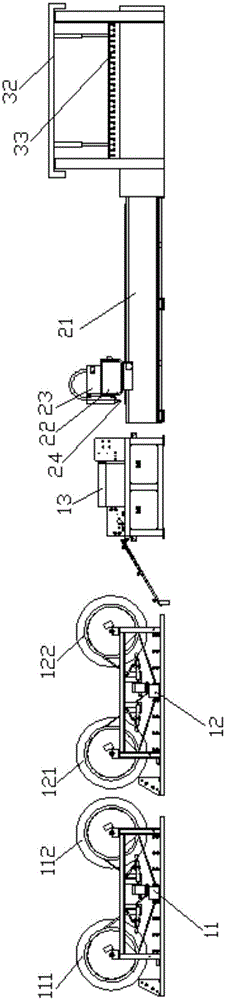

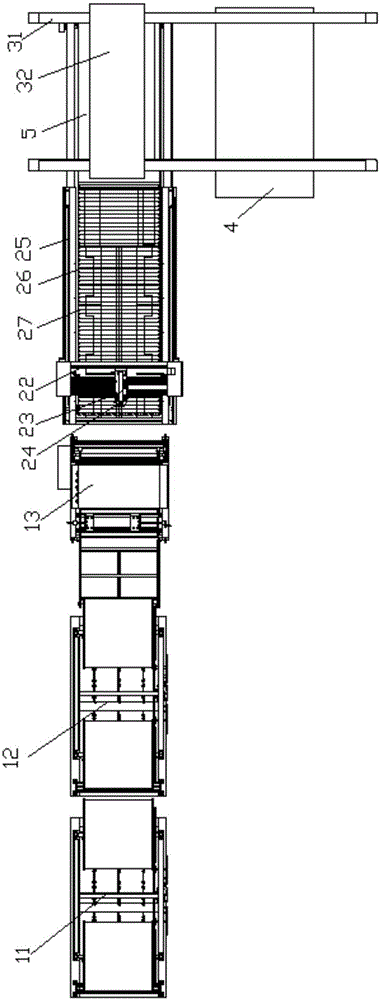

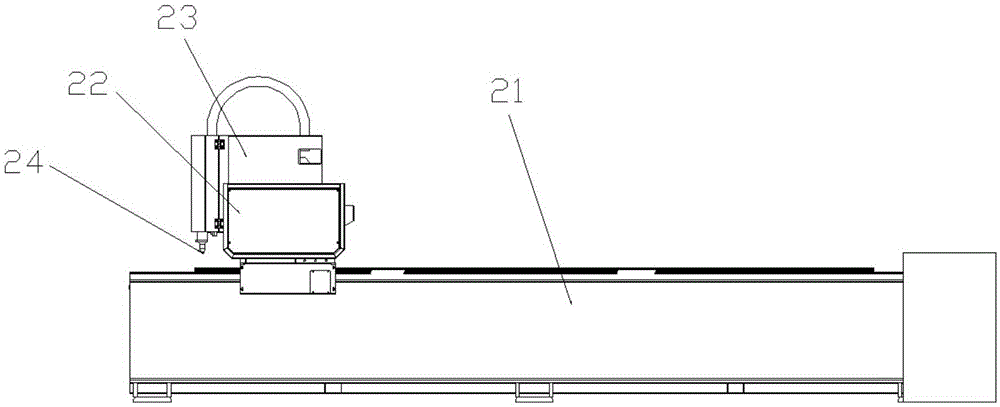

[0021] Such as Figure 1-4 As shown, a laser flexible processing system is provided, including an automatic uncoiling system, a laser cutting system, an automatic unloading system and a sorting table, wherein the automatic uncoiling system includes a main uncoiling line 11, a backup uncoiling line 12, and a main uncoiling line 11 The first drum 111 and the second drum 112 are respectively arranged at the two ends of the two ends, and the third drum 121 and the fourth drum 122 are respectively arranged at the two ends of the spare uncoiling line 12. Of course, the number of spare uncoiling lines can be increased according to the production line demand or Cancellation, the plates of different specifications are wound on the first roller 111 and the second roller 112 respectively, and when processing is required, the plates of corresponding specifications are transported. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com