Building block forming rotation platform type press

A rotary platform and platform-type technology, applied in ceramic molding machines, supply devices, unloading devices, etc., can solve the problems of insufficient block hardness, high requirements, and rising transportation costs, and achieve simple structure, low production cost, The effect of reducing the hardening phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

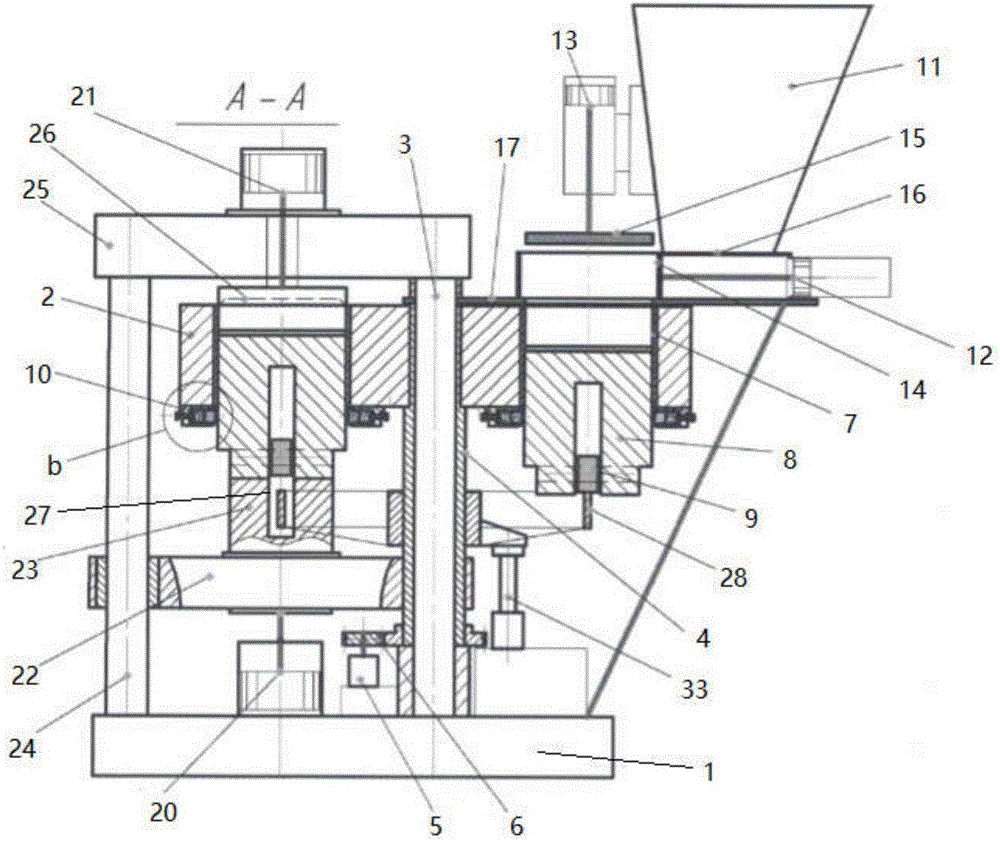

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

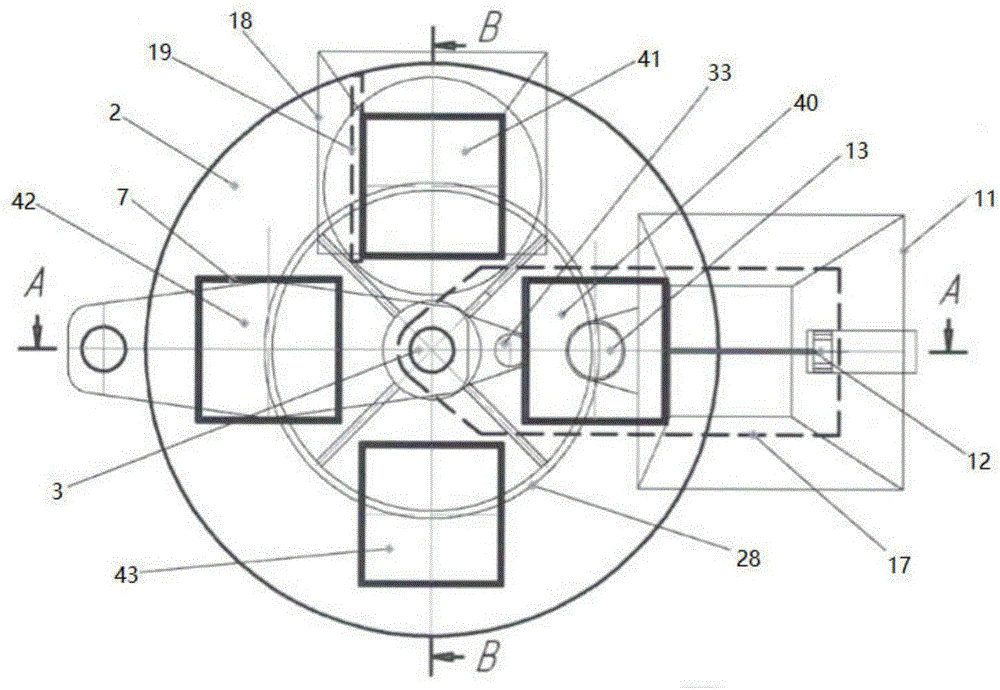

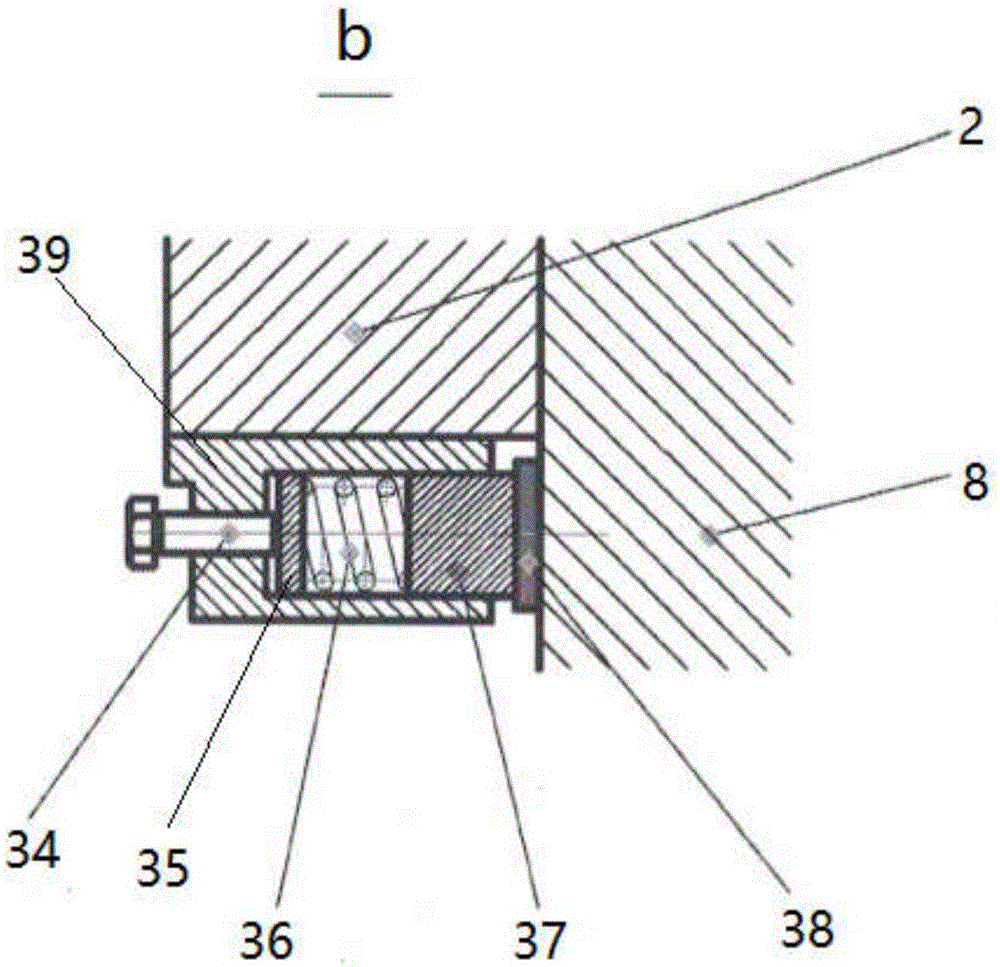

[0017] As shown in the figure: a block forming rotary platform press, characterized in that it includes a frame 1, a packing mechanism I, a packing mechanism II, a pressing mechanism, a block pushing mechanism, a rotating platform 2, a central shaft 3, and a hollow shaft 4. Driving motor 5; the central shaft 3 is mounted on the frame 1; the driving motor 5 is mounted on the frame 1, next to the central shaft 3; the hollow shaft 4 is set on the central shaft 3 On the top, driven by the driving motor 5, it can rotate around the central shaft 3 through the meshing transmission of the gear 6; the rotating platform 2 is installed and fixed on the hollow shaft 4, and can rotate with the hollow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com