T-shaped empennage and aircraft with same

A tail and aircraft technology, applied in the aviation field, can solve the problems of reduced trimming capability of the horizontal tail, affecting the efficiency of the horizontal tail, unreasonable design of the joints, etc., so as to reduce mutual interference, simplify redundant design, and increase the efficiency of the horizontal tail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

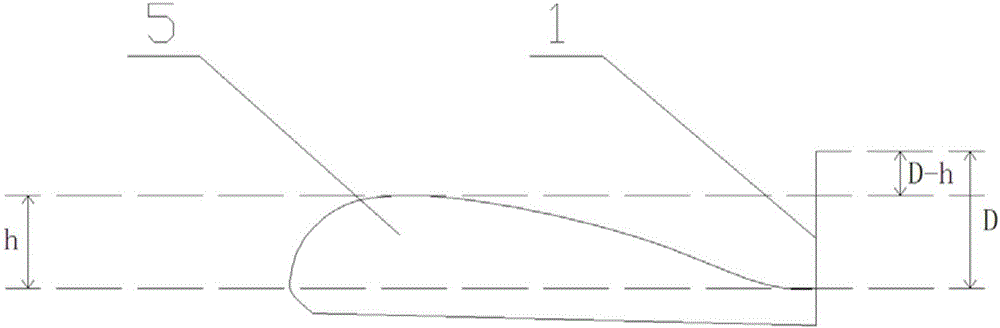

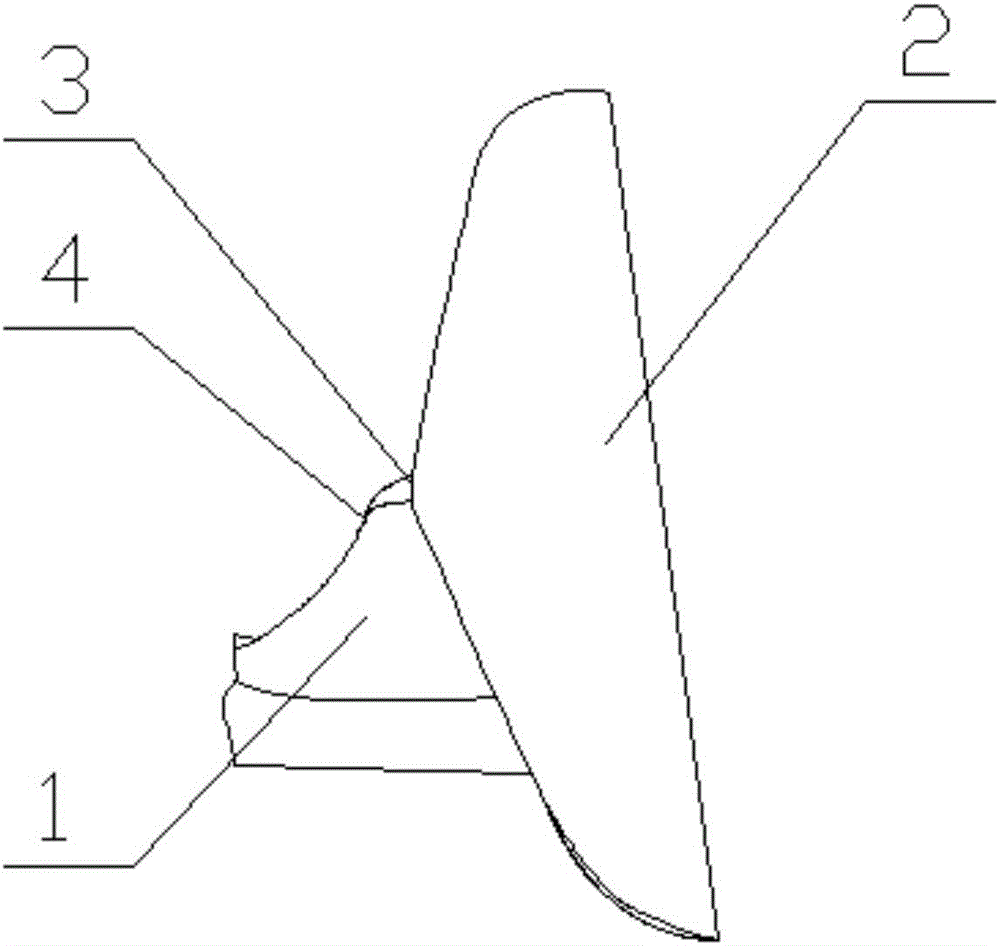

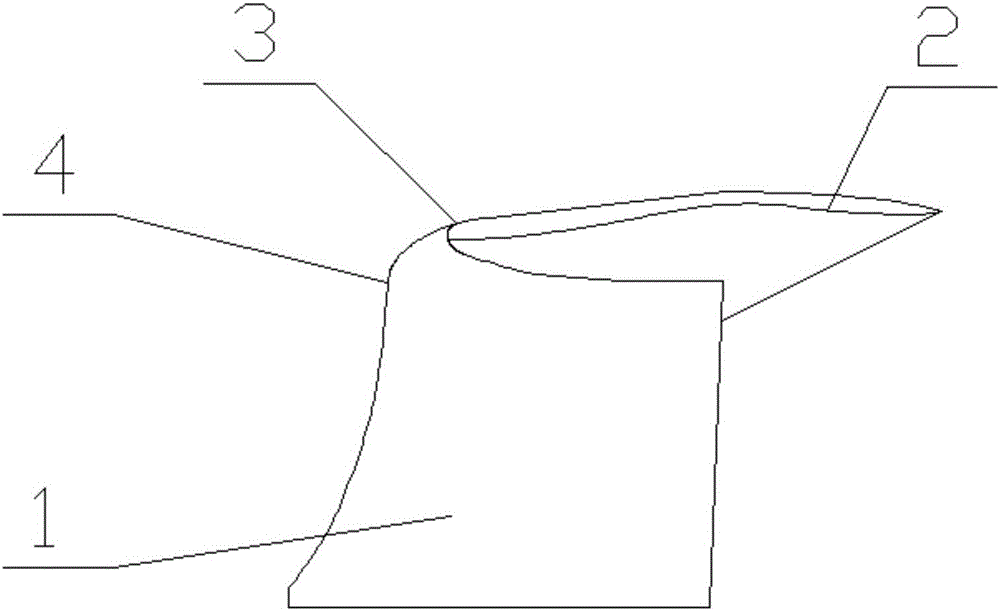

[0028] Such as Figure 1-3 As shown, a T-shaped tail includes a vertical tail 1 and a horizontal tail 2, and the joints of the vertical tail 1 and the horizontal tail 2 are arranged alternately. The specific distribution of the junction of the vertical tail 1 and the horizontal tail 2 is as follows: the front end 3 of the horizontal tail 2 is arranged behind the front edge 4 of the horizontal tail 2 . The height of the vertical tail 1 is D, the height of the fuselage 5 is h, the height difference between the vertical tail 1 and the fuselage 5 is D-h, D-h=1 / 2D. The height of the fuselage 5 is specifically: the height difference between the top of the fuselage 5 and the root of the vertical tail 1 .

[0029] An aircraft equipped with a T-shaped tail, the aircraft includes a fuselage 5, the tail of the fuselage 5 is provided with a T-shaped tail, the T-shaped tail includes a vertical tail 1 and a horizontal tail 2, and the horizontal tail 2 is symmetrical Airfoil, the root of t...

Embodiment 2

[0031] Such as Figure 1-3 As shown, a T-shaped tail includes a vertical tail 1 and a horizontal tail 2, and the joints of the vertical tail 1 and the horizontal tail 2 are arranged alternately. The specific distribution of the junction of the vertical tail 1 and the horizontal tail 2 is as follows: the front end 3 of the horizontal tail 2 is arranged behind the front edge 4 of the horizontal tail 2 . The height of the vertical tail 1 is D, the height of the fuselage 5 is h, the height difference between the vertical tail 1 and the fuselage 5 is D-h, D-h=2 / 3D. The height of the fuselage 5 is specifically: the height difference between the top of the fuselage 5 and the root of the vertical tail 1 .

[0032] An aircraft equipped with a T-shaped tail, the aircraft includes a fuselage 5, the tail of the fuselage 5 is provided with a T-shaped tail, the T-shaped tail includes a vertical tail 1 and a horizontal tail 2, and the horizontal tail 2 is symmetrical Airfoil, the root of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com