Separate collection, reuse and treatment method for SCR denitration catalyst cleaning wastewater

A denitration catalyst and a technology for cleaning wastewater, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of reduced reliability, high energy consumption, complicated devices, etc., and achieve simple wastewater treatment methods, and The effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

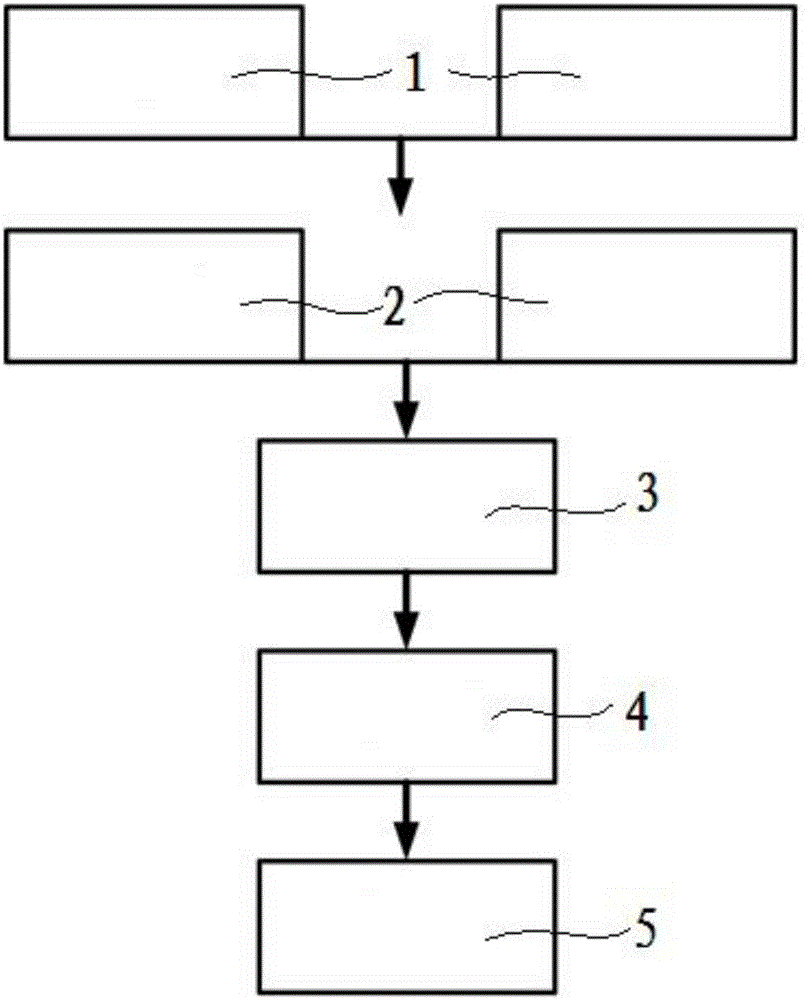

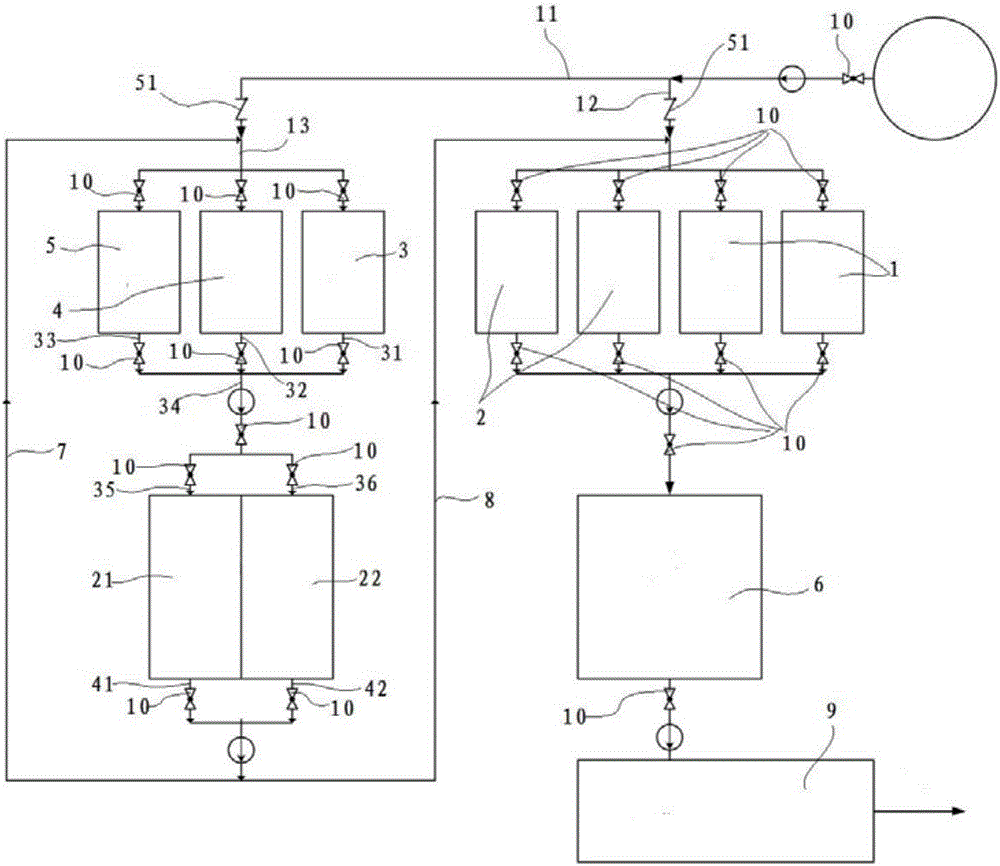

Method used

Image

Examples

Embodiment 1

[0045] After the fifth cleaning tank 5 cleans 12 pieces of catalyst, it is recorded as time point 1, and the waste water is discharged into the left collection tank 21 of the second waste water collection tank, and then new desalted water is injected to continue the pipeline cleaning of the catalyst module. After the waste water in the left collection tank 21 of the second waste water collection tank was allowed to settle for 24 hours, the measured pH value of the supernatant was 5.9, and the turbidity was 13 NTU. After the fourth cleaning tank 4 cleans 24 pieces of catalysts, it is recorded as time point 2, waste water is discharged into the right collecting tank 22 of the second wastewater collecting tank, then the supernatant liquid injected into the left collecting tank 21 is reused, and the insufficient Part of it is supplemented with demineralized water, and the pipeline cleaning of the catalyst module is continued. After the waste water in the right collection tank 22 o...

Embodiment 2

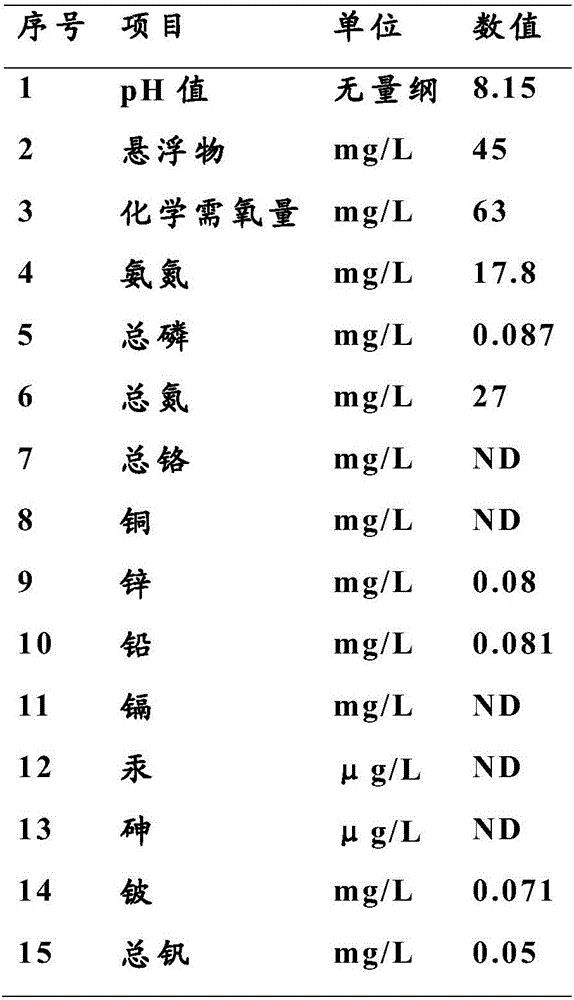

[0048] After cleaning 20 pieces of catalysts in the first cleaning tank 1 and the second cleaning tank 2 , the waste water is discharged into the first waste water collection tank 6 . The measured wastewater pH value is 3.1, and the turbidity exceeds the instrument range (>1000NTU). Add an appropriate amount of sodium hydroxide to the first wastewater collection tank 6 and aerate for neutralization. After 2 hours of reaction, it was left to settle for 24 hours. The measured pH value of the supernatant was 8.6, and the turbidity was 113 NTU. Extract the supernatant and discharge it to the waste water continuous treatment device 9, add PAC and PAM online, the dosage of PAC is 800-1500ppm, and the dosage of PAM is 5-10ppm. Then after the subsequent inclined tube settling and filtration of fine sand and activated carbon, clean water is obtained. The pH value of the clear water is 8.3, the turbidity is 14, and the content of heavy metal elements is shown in Table 1.

[0049] Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com