Ultrasonic water purification component easy to manufacture

A technology of ultrasonic waves and components, applied in the field of water purification equipment, can solve the problems of not achieving the water purification effect, troublesome production methods, increased costs, etc., and achieve the effect of improving the water purification effect, preventing the induction of diseases, and eliminating the harm of mites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

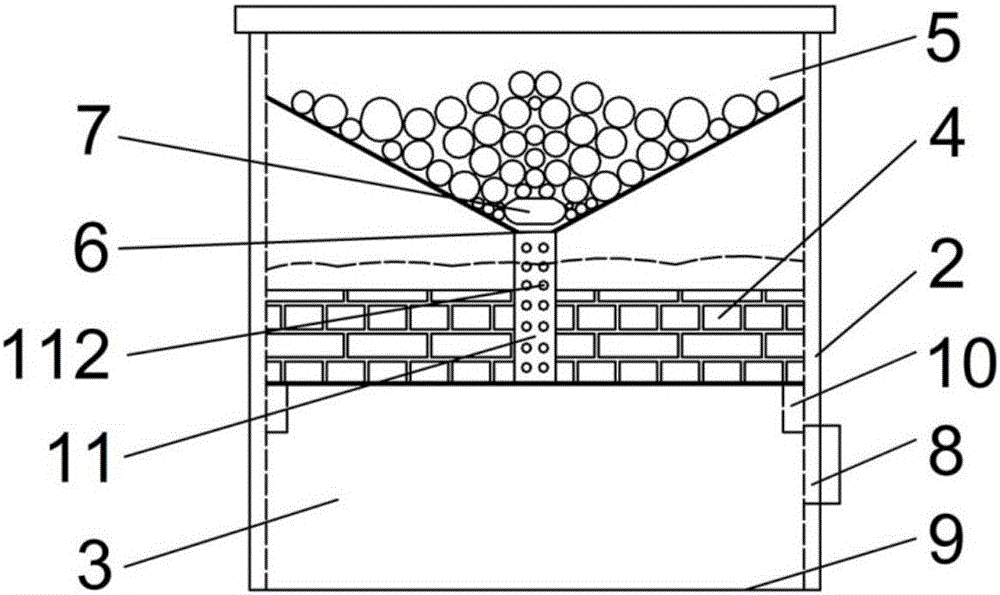

[0015] An easy-to-manufacture ultrasonic water purification component includes a shell 2. In order to make the whole device more beautiful and expand its scope of application, the shell 2 is set in a cylindrical shape, and the inside of the shell 2 is arranged as an ultrasonic purification layer 3 from bottom to top (i.e. Ultrasonic mite removal instrument 8), activated carbon adsorption layer 4 (mainly filled with activated carbon) and pebble layer 5 (as the name suggests, filled with pebbles) are installed, and the bottom of ultrasonic purification layer 3 is sealed with water filter paper 9, water filter paper 9 The inner wall of the ultrasonic purification layer (3) above is provided with a limit block 10, preferably, the limit block 10 is ring-shaped, fixed on the inner wall of the ultrasonic purification layer 3, and is mainly used for installing a water holding device (such as a bucket or a water cup) and fixed filter gauze; the ultrasonic cleaning layer 3 is connected w...

Embodiment 2

[0026] The difference from Example 1 is that the filter port 6 is used as the boundary line between the activated carbon adsorption layer 4 and the cobblestone layer 5, and the filter port 6 is fixed with a guide tube 11, and the tube wall of the guide tube 11 is provided with evenly distributed outlets. Nozzle 112.

[0027] Further, in order to coarsely filter the water quality, a filter screen is sealed on the filter port 6 , and the filter screen is arranged between the filter port 6 and the guide pipe 11 .

Embodiment 3

[0029] The difference from Examples 1 and 2 is that the activated carbon adsorption layer 4 not only includes activated carbon, but also includes molecular sieves, volcanic ash, medical stone or a combination thereof. Due to the limited adsorption effect of a single material, the main adsorbed objects of different materials are also different. Therefore, in order to better the adsorption effect, this embodiment uses two or more adsorption materials combined, and each material does not need to be layered. Distinct arrangement, mixed together also works well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com