Production process of mirror-surface synthetic leather

A production process and technology for synthetic leather, applied in the field of synthetic leather, can solve the problems of prolonged production process route, energy waste, etc., and achieve the effects of smooth surface, excellent folding resistance and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

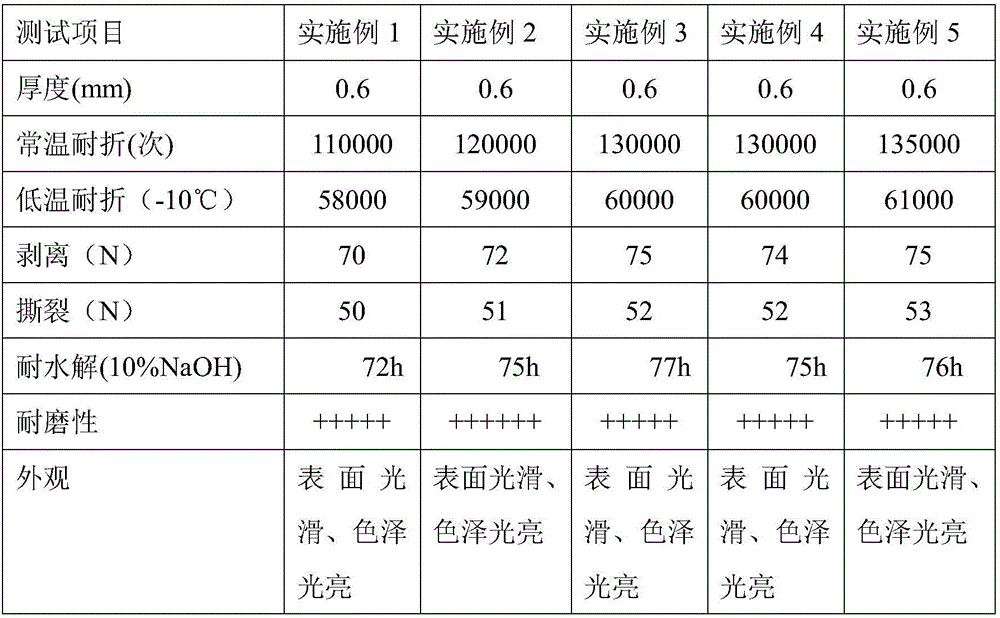

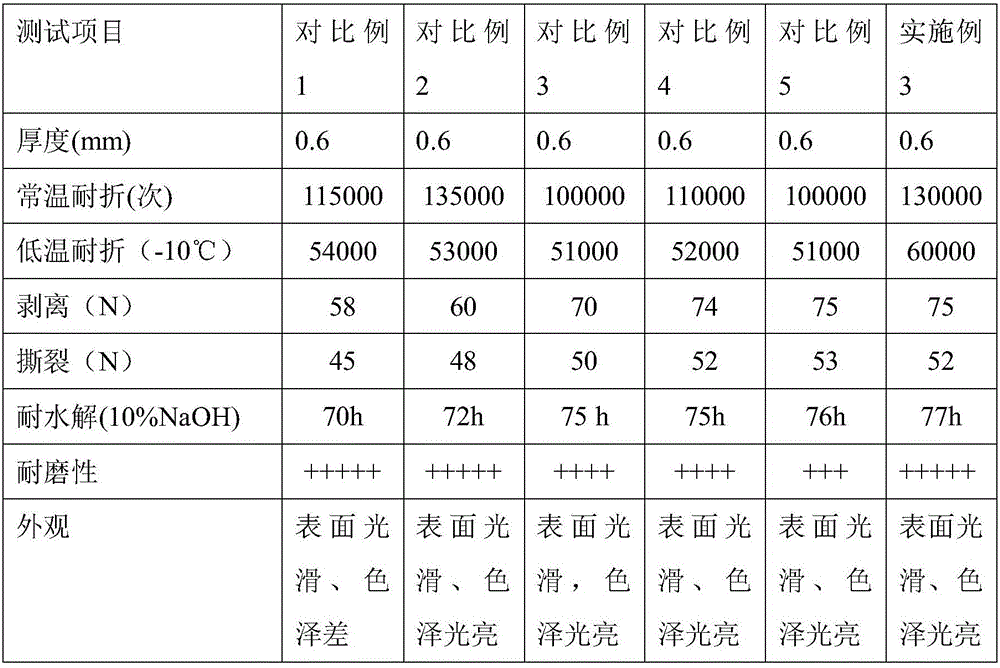

Examples

Embodiment 1

[0043] Step 1: Prepare the base cloth, prepare wet slurry and dry slurry, wherein the wet slurry includes the following components by weight, 80 parts of polyurethane resin, 150 parts of DMF, 5 parts of wood powder, 5 parts The calcium carbonate of 3 parts, the color paste of 3 parts, the dry process slurry comprises the component of following parts by weight, 100 parts of waterborne polyurethane resin, 5 parts of DMF, 5 parts of acetone, 5 parts of polytetrafluoroethylene, 1 part of polyacrylamide, 1 part of erucamide, 1 part of color paste;

[0044] Step 2: The base fabric is unrolled, passes through the fabric storage rack, and arrives at the coating machine, where it is coated with wet slurry, a mixture of DMF and water with a volume ratio of 1:3, solidified, washed with water, baked at 170°C for 5 minutes, and collected after cooling roll to generate bass;

[0045] Step 3: After coating the dry-process slurry on the release paper, bake at 125°C for 5 minutes;

[0046] S...

Embodiment 2

[0051] Step 1: Prepare the base cloth, prepare wet slurry and dry slurry, wherein the wet slurry includes the following components by weight, 90 parts of polyurethane resin, 160 parts of DMF, 6 parts of wood powder, 6 parts Parts of calcium carbonate, 4 parts of color paste, dry paste includes the following components by weight, 110 parts of water-based polyurethane resin, 7 parts of DMF, 6 parts of acetone, 6 parts of polytetrafluoroethylene, 2 parts of polyacrylamide, 2 parts of erucamide, 2 parts of color paste;

[0052] Step 2: The base fabric is unrolled, passes through the fabric storage rack, and arrives at the coating machine, where it is coated with wet slurry, a mixture of DMF and water at a volume ratio of 1:4, solidified, washed with water, baked at 180°C for 6 minutes, and collected after cooling roll to generate bass;

[0053] Step 3: After coating the dry-process slurry on the release paper, bake at 130°C for 6 minutes;

[0054] Step 4: After drying, continue ...

Embodiment 3

[0059] Step 1: Prepare the base cloth, prepare wet slurry and dry slurry, wherein the wet slurry includes the following components by weight, 100 parts of polyurethane resin, 175 parts of DMF, 7.5 parts of wood powder, 7.5 parts Parts of calcium carbonate, 5 parts of color paste, dry paste includes the following components by weight, 125 parts of water-based polyurethane resin, 10 parts of DMF, 7.5 parts of acetone, 7.5 parts of polytetrafluoroethylene, 3 parts of polyacrylamide, 1 part of erucamide, 3 parts of color paste;

[0060] Step 2: The base fabric is unrolled, passes through the fabric storage rack, and arrives at the coating machine, where it is coated with wet slurry, a mixture of DMF and water with a volume ratio of 1:5, solidified, washed with water, baked at 190°C for 7 minutes, and collected after cooling roll to generate bass;

[0061] Step 3: After coating the dry-process slurry on the release paper, bake at 135°C for 7 minutes;

[0062] Step 4: After drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com