Novel sucker and spring type energy dissipation damper

A spring-type, suction-cup technology, applied in building types, protective buildings/shelters, building components, etc., can solve the problems of high damper design requirements, complex construction technology, difficult processing, etc., and achieve strong energy absorption capacity. , the effect of alleviating the impact and increasing the space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

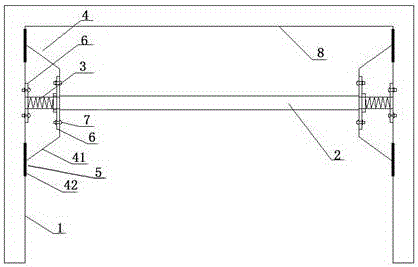

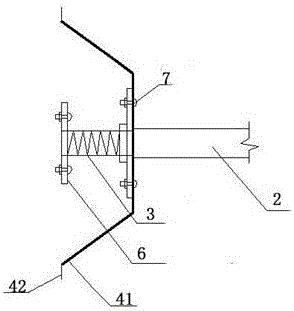

[0014] Such as figure 1 , figure 2 As shown, a new type of suction cup spring type energy dissipation damping includes a steel rod 2 arranged between two columns 1, a beam 8 is connected between the two columns 1, and the two ends of the steel rod 2 are connected with elastic connectors 3 and rubber The suction cup 4, the elastic connector 3 is a spring, the rubber sucker 4 is set on the outside of the elastic connector 3, the column 1 is provided with a rubber sealing surface 5, the rubber sucker 4 is adsorbed on the rubber sealing surface 5, the two elastic connectors 3 The ends are respectively connected to the inner side of the column 1 and the rubber suction cup 4 through the fixing mechanism. The fixing mechanism includes a fixed backing plate 6 and high-strength bolts 7 pierced on the fixing backing plate 6. Inner fixed connection.

[0015] The rubber suction cup 4 includes a suction cup main body 41 and a sealing ring 42 located on the outer edge of the suction cup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com