Steel platform formwork lifting point bearing beams and lifting method for formwork system

A hoisting method and technology of steel platform, applied in formwork/template/work frame, processing of building materials, preparation of building components on site, etc. Convenience, simple structure, simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

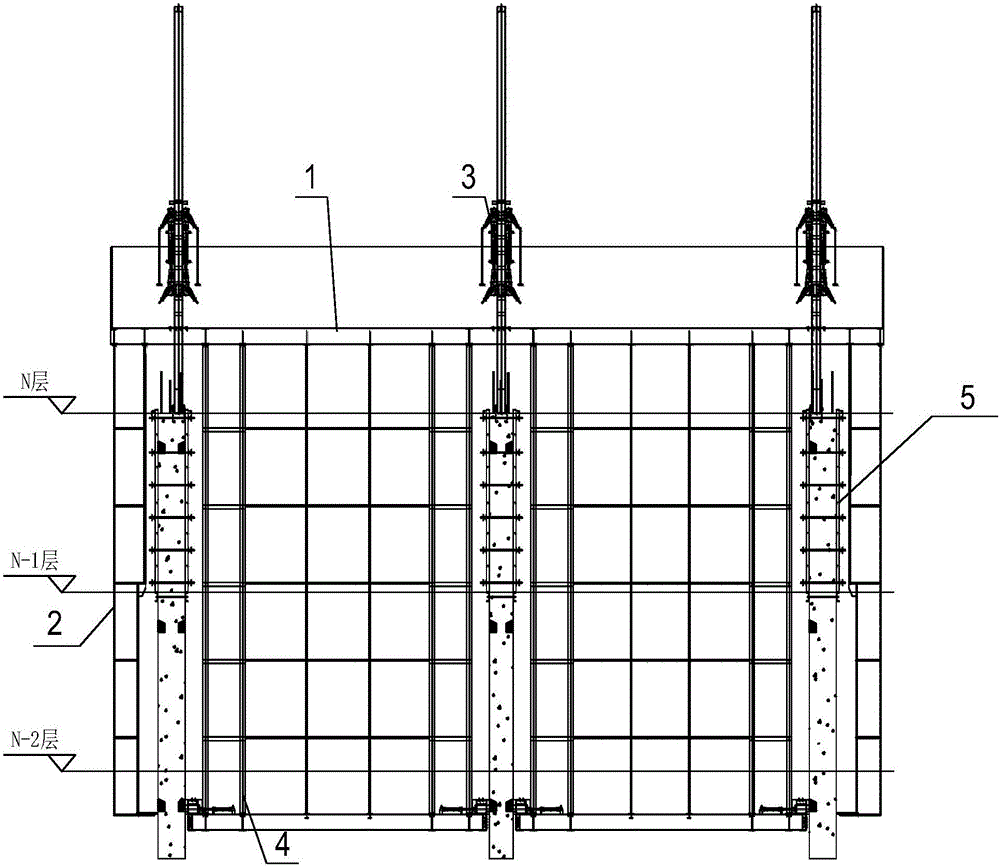

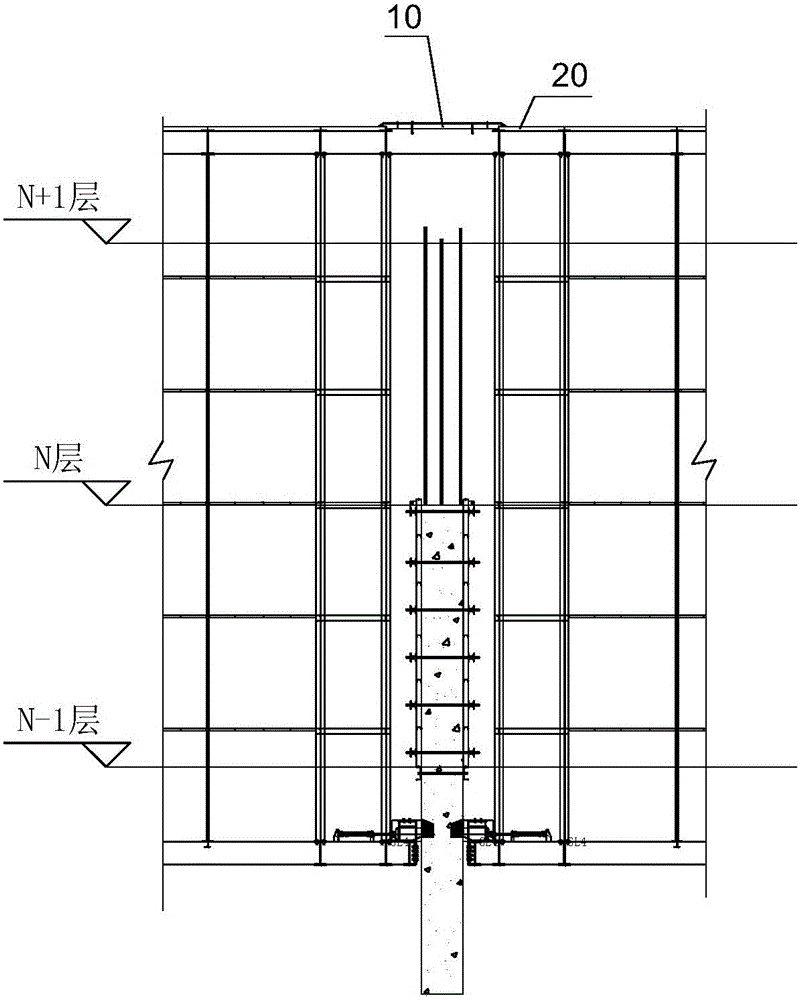

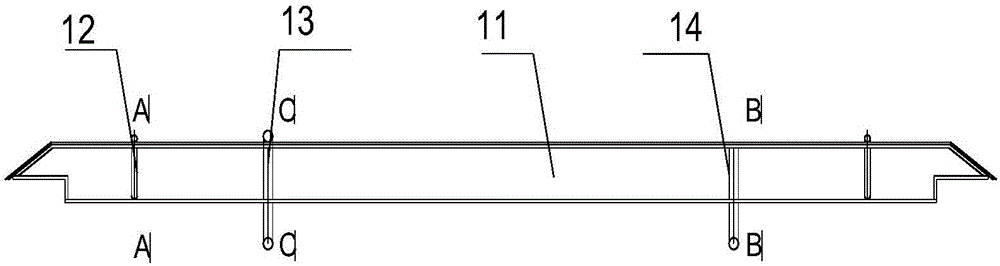

[0037] see Figure 2 to Figure 6 , the hydraulic climbing integral steel platform formwork system is fixed on the vertical concrete structure of the core tube, and the load-bearing beam 1 of the formwork lifting point is arranged across the top of the formwork of the core wall wall so that it is perpendicular to the horizontal direction of the shear wall, that is, the formwork hanging The point load-bearing beam 1 is set across the steel platform, located above the shear wall of the core tube, and spans the opening of the steel platform. The formwork hanging point load-bearing beam 10 includes: the main beam 11, which is embedded in the steel platform decking The upper surface of 20; the handle ring 12, the handle ring 12 is arranged at the two ends of the main beam 11; at least one movable ring 13, the movable ring 13 surrounds the main beam 11, and can follow the closing of the wall along the The main girder 11 slides and is located on the shrinking side of the wall of the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap