Stainless steel box for repairing hoisting reserving holes of reinforced concrete roofs of prilling tower and silo and repairing method

A technology for reinforced concrete and granulation towers, applied in building maintenance, building construction, construction, etc., can solve the problems of unfavorable durability of granulation towers, difficult removal of wooden formwork 54, and impossibility of anti-corrosion construction, etc., to achieve convenient on-site production, Reduce construction cost and ensure anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

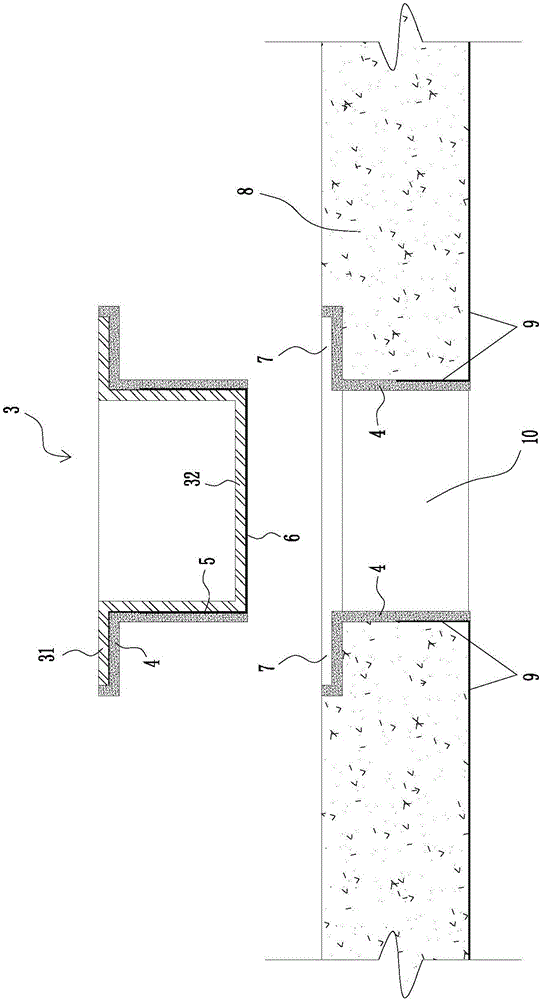

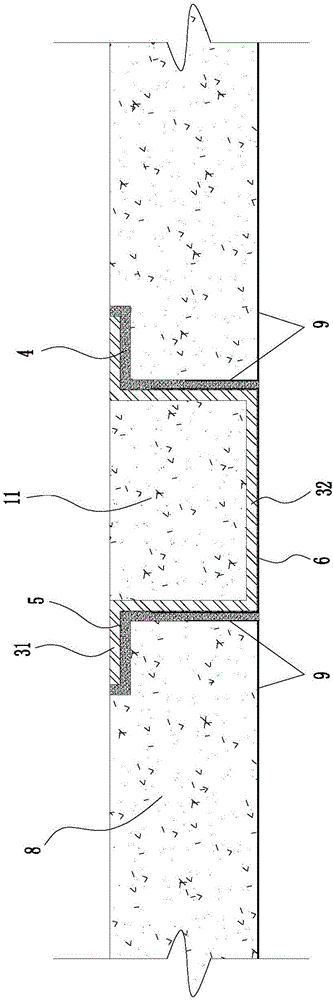

[0022] A method for repairing holes left in hoisting reinforced concrete roofs of prilling towers and silos according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0023] Such as figure 1 , figure 2 with image 3 As shown, in this specific embodiment, a method for repairing holes left in hoisting reinforced concrete roofs of prilling towers and silos of the present invention includes the following steps:

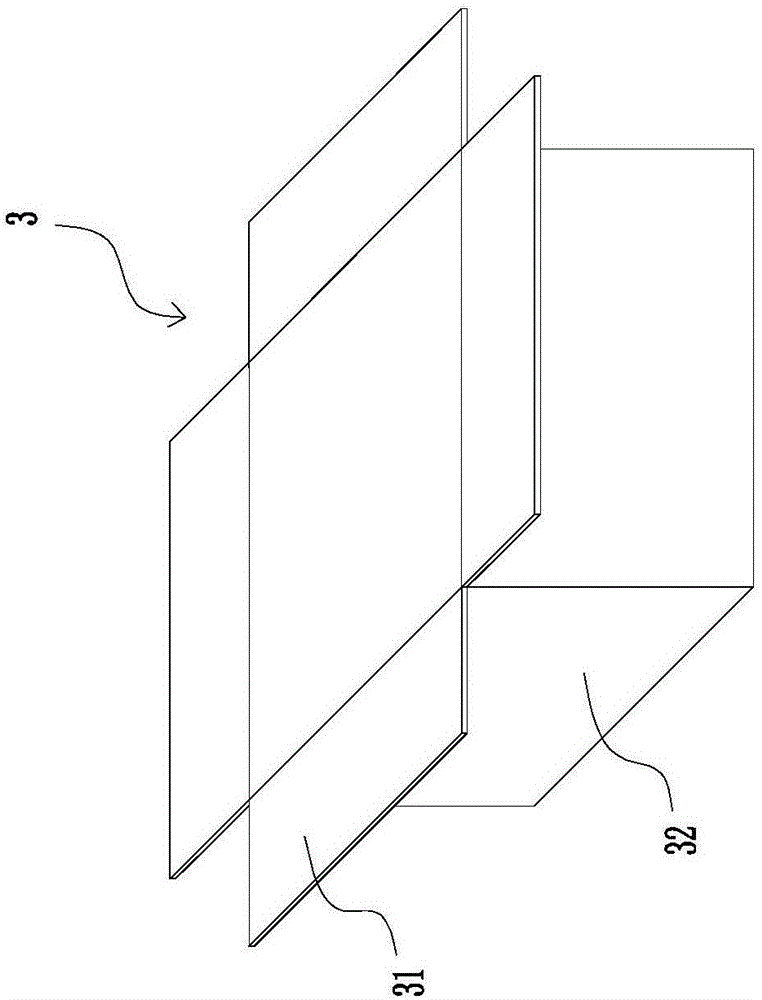

[0024] 1) According to the shape of the hoisting hole 10, a stainless steel box 3 is made of a stainless steel plate with a thickness of 2.5 mm (of course, other values between 2 and 3 mm can be used). The stainless steel box 3 includes a box body 32, and the top of the box body 32 is open , an outwardly bent bending plate 31 is arranged on the edge of the opening, the bending plate 31 is perpendicular to the outer wall of the box body 32, and the size of the box body 32 is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com