A kind of NdFeB magnetic material compounded with lanthanide elements and its preparation method

A magnetic material and compound additive technology, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve problems such as high production costs, waste of rare earth resources, and poor corrosion resistance, and achieve process improvement and reduction The distribution of grain boundary rich phase structure and the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Ingredients: Proportion according to the contents stated in the following composition ratio table.

[0033] Taking the smelting of 600Kg NdFeB alloy as an example, the distribution ratio of each component is shown in Table 1-1:

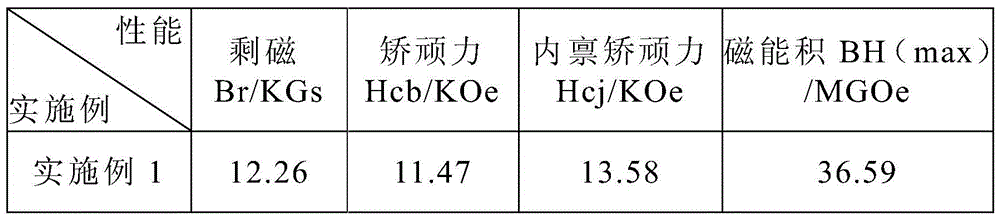

[0034] Table 1-1: Each component distribution ratio (mass percentage %) in embodiment 1

[0035] Element Nd B La co Cu Ti Al Nb Ga Fe Embodiment one 21 1.05 10 0.5 0.20 0.4 0.6 0.3 0.2 margin

[0036] According to the above proportioning composition, the raw materials are mixed and put into the vacuum belt furnace.

[0037] (1) Melting: The raw materials that have been cleaned on the surface are prepared according to the alloy composition ratio; placed in a vacuum belt furnace, when the air in the vacuum belt furnace is evacuated to 4-5Pa, heating and melting begins, until the furnace When the inner ingredients turn red, close the vacuum valve, fill in argon to 0.4MPa, and raise the temperature t...

Embodiment 2

[0046] Ingredients: Proportion according to the contents stated in the following composition ratio table.

[0047] Taking the smelting of 600Kg NdFeB alloy as an example, the distribution ratio of each component is shown in Table 2-l:

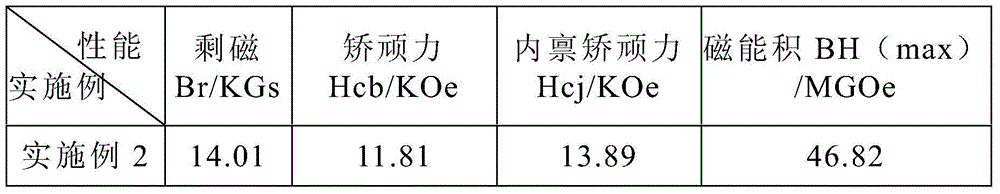

[0048] Table 2-1: Each component distribution ratio (mass percentage %) in embodiment 2

[0049] Element PrN B La Ce co Cu Ti Al Nb Ga Fe Example 2 28.5 1.05 1 1 1.0 0.12 0.1 0.2 0.2 0.1 margin

[0050] According to the above proportioning composition, the raw materials are mixed and put into the vacuum belt furnace.

[0051] (1) Melting: The raw materials that have been cleaned on the surface are prepared according to the alloy composition ratio; placed in a vacuum belt furnace, when the air in the vacuum belt furnace is evacuated to 4-5Pa, heating and melting begins, until the furnace When the inner ingredients turn red, close the vacuum valve, fill in argon to 0.5MPa, and raise the temperat...

Embodiment 3

[0060] Ingredients: Proportion according to the content stated in the following composition ratio table

[0061] Taking the smelting of 600Kg NdFeB alloy as an example, the distribution ratio of each component is shown in Table 3-l:

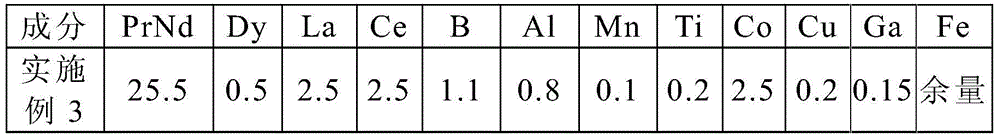

[0062] Table 3-1: Each component distribution ratio (mass percentage %) in embodiment 3

[0063]

[0064] According to the above proportioning composition, the raw materials are mixed and put into the vacuum belt furnace.

[0065] (1) Melting: The raw materials that have been cleaned on the surface are prepared according to the alloy composition ratio; placed in a vacuum belt furnace, when the air in the vacuum belt furnace is evacuated to 5-8Pa, heating and smelting is started, until the furnace When the inner ingredients turn red, close the vacuum valve, fill in argon to 0.5MPa, and raise the temperature to 1480°C until the ingredients are completely melted, then refine for 10-15 minutes, and adjust the power to 80KW for pouring after the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com