Bonded polyolefine resin composition

A technology of polyolefin resin and composition, which is applied in the field of polyolefin resin composition to achieve the effects of preventing damage, increasing grafting rate, and reducing degradation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] With the dicumyl peroxide initiator, the homopolypropylene (Lanzhou Petrochemical Company F401) with a melt flow rate of 2.5g / 10min and MAH, styrene with a weight ratio of 10:1:0.25 (initiator is 0.125wt ‰)exist Reaction in the co-rotating twin-screw, the reaction temperature (°C) of each stage of the screw is 170, 180, 190, 200, 210, 210, 210, 190, 180, 170; reaction time: 6min. The grafting rate of MAH on polypropylene was determined to be 2%;

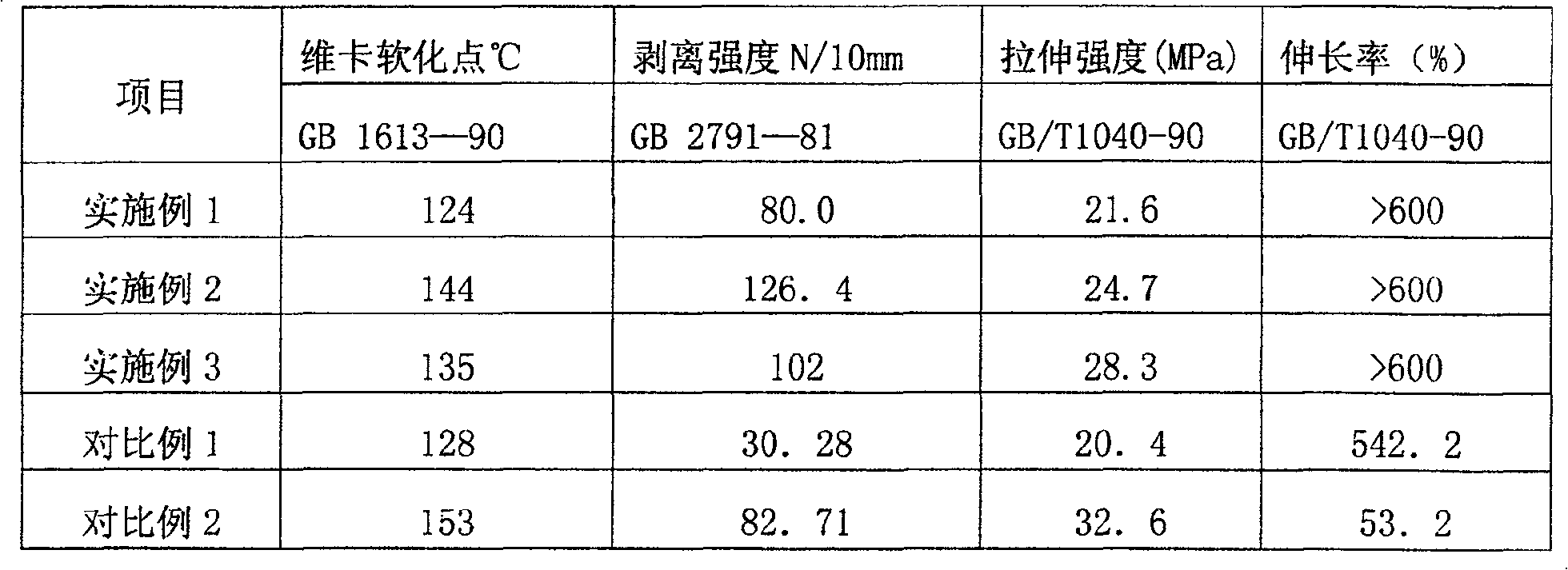

[0036] According to the following ratio in Blending in co-rotating twin-screws, adding primary antioxidant 1010 and secondary antioxidant 168 (both produced by Jinhai Yabao) during the blending, and their dosage accounts for 0.5‰ and 1‰ of the total mass of the composition, respectively. The temperature (℃) of each section of the screw is: 200, 210, 220, 230, 230, 240, 230, 220, and the screw speed is 60 rpm. The performance test results of the obtained products are shown in Table 1.

[0037] Polypropylene-g-MAH 5

[00...

Embodiment 2

[0054] With dicumyl peroxide as the initiator, block polypropylene (Yanshan Petrochemical 7726) with a melt flow rate of 28g / 10min and MAH, styrene in a weight ratio of 10:1:0.25 (the initiator is 0.125wt‰ )exist Reaction in the co-rotating twin-screw, the reaction temperature (°C) of each section of the screw is 170, 180, 190, 200, 210, 210, 210, 190, 180, 170; reaction time: 6min, MAH relative grafting rate is 4% grafted polypropylene;

[0055] According to the following ratio in Blending in co-rotating twin-screws, adding primary antioxidant 1010 and secondary antioxidant 168 (both produced by Jinhai Yabao) during the blending, and their dosage accounts for 0.5‰ and 1‰ of the total mass of the composition, respectively. The temperature (℃) of each section of the screw is: 200, 210, 220, 230, 230, 240, 230, 220, and the screw speed is 60 rpm. The performance test results of the product are shown in Table 1.

[0056] Polypropylene-g-MAH 20

[0057] Polypropylene (melt ...

Embodiment 3

[0063] Use block polypropylene (Yanshan Petrochemical 7726) with a melt flow rate of 28g / 10min to MAH and styrene at a weight ratio of 10:1:0.25 (the initiator is 0.125wt‰) in a 2L three-necked flask with xylene. Solvent reaction temperature 100 (°C); reaction time: 2h solution grafting, grafted polypropylene with a relative grafting rate of MAH of 7%;

[0064] According to the following ratio in Blending in co-rotating twin-screws, adding primary antioxidant 1010 and secondary antioxidant 168 (both produced by Jinhai Yabao) during the blending, and their dosage accounts for 0.5‰ and 1‰ of the total mass of the composition, respectively. The temperature (℃) of each section of the screw is: 200, 210, 220, 230, 230, 240, 230, 220, and the screw speed is 60 rpm. The performance test results of the product are shown in Table 1.

[0065] Polypropylene-g-MAH 28

[0066] Polypropylene (melt flow rate 2.5g / 10min) 20 Lanzhou Petrochemical F401

[0067] LLDPE (melt flow rate 1.0g / 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com