Split-type spiral drilling machine

A kind of auger drilling rig, split type technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of low drilling efficiency, no open horizontal auger drilling rig, and inconvenient movement, so as to avoid pipeline laying and facilitate lifting and moving Sexuality, the effect of simplifying the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

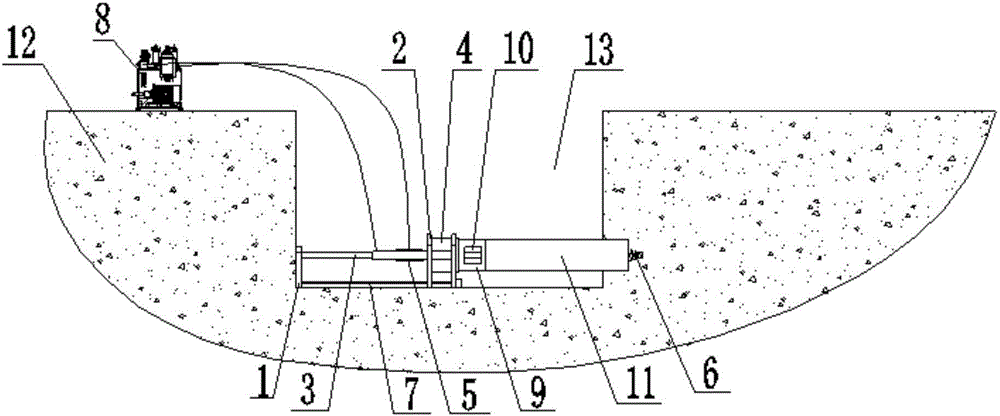

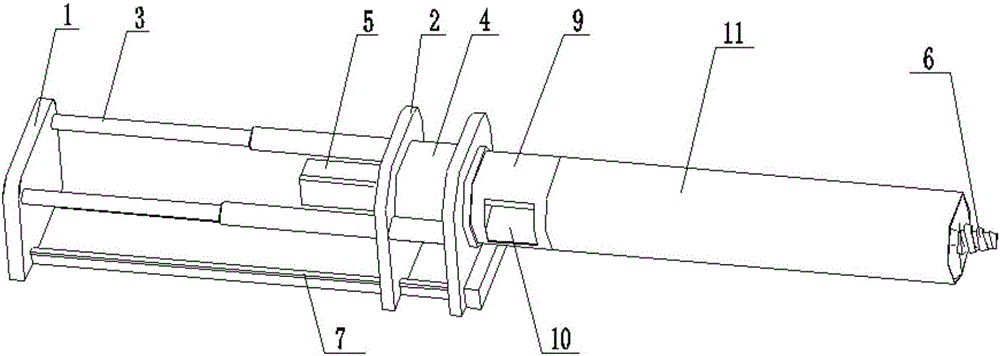

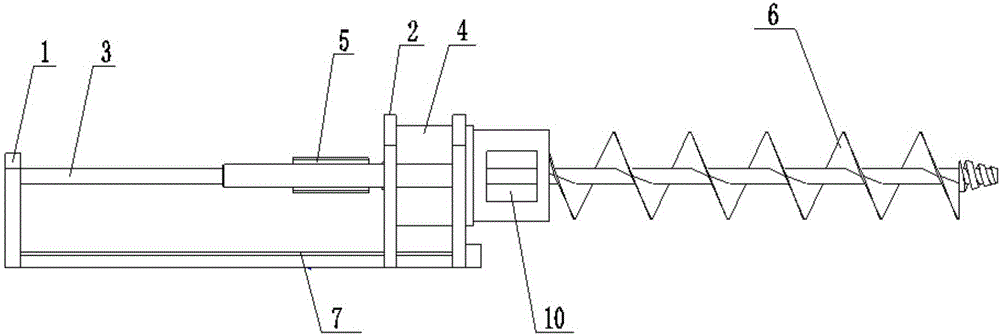

[0021] Such as Figure 1 to Figure 3 As shown, a split type auger drill includes a frame 1, a support frame 2, an oil cylinder 3, a reduction gear 4, a hydraulic motor 5 and an auger bit 6; the bottom of the frame 1 is provided with a guide rail 7, and the support frame 2 moveably placed on the guide rail 7; two oil cylinders 3 are provided, the output shafts of the two oil cylinders 3 are fixedly connected with the frame 1, and the two oil cylinders 3 are far away from their output shafts One end of each is fixedly connected with the support frame 2, and the output shafts of the two oil cylinders 3 expand and contract to drive the support frame 2 to move on the guide rail 7; the speed reduction device 4 is placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com