A Diesel Engine Spiral Auxiliary Intake Port

A technology for air intakes and diesel engines, applied to fuel air intakes, mechanical equipment, engine components, etc., can solve the problems of insufficient intake air quality and intake kinetic energy, poor fuel economy of diesel engines, and high emission levels. The effect of increasing kinetic energy, strengthening the strength of vortex, and fully burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

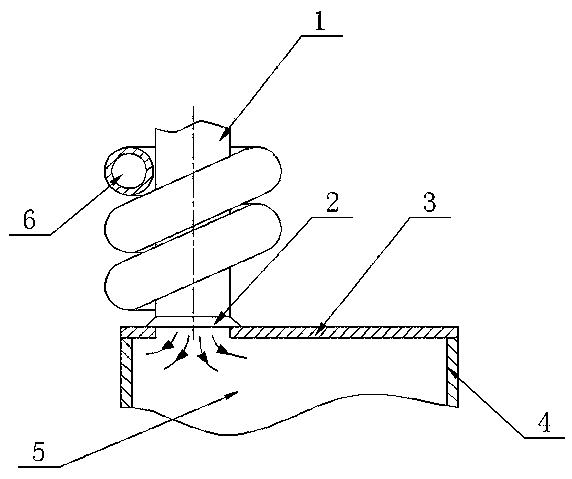

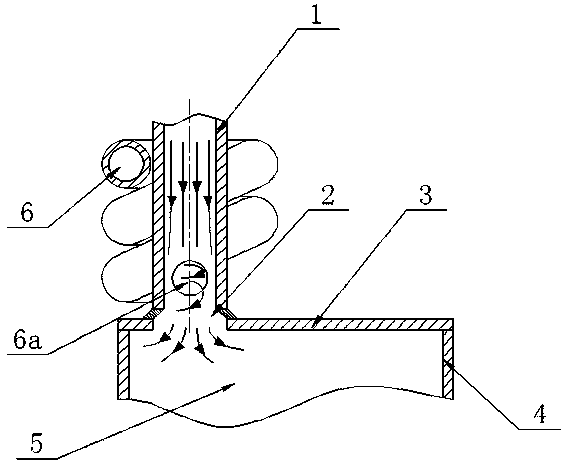

[0017] figure 1 , 2 , 3 shows the structure diagram and cross-sectional view of the first type of spiral auxiliary intake port 6. The gas passes through the first type of spiral auxiliary intake port 6 which spirals around the intake port 1, and is arranged near the intake valve seat 2. The first spiral auxiliary inlet port 6a of the first type of spiral auxiliary inlet enters the inlet port 1, and the connection between the inlet port 1 and the first type spiral auxiliary inlet port 6 adopts a smooth transition to reduce the energy loss of the gas flowing through here. The gas entering the combustion chamber 5 increases the momentum in the vertical direction of the axis of the combustion chamber 5, and the swirl intensity of the gas entering the combustion chamber 5 is obviously increased, which can quickly make the fuel and air form a more uniform mixture.

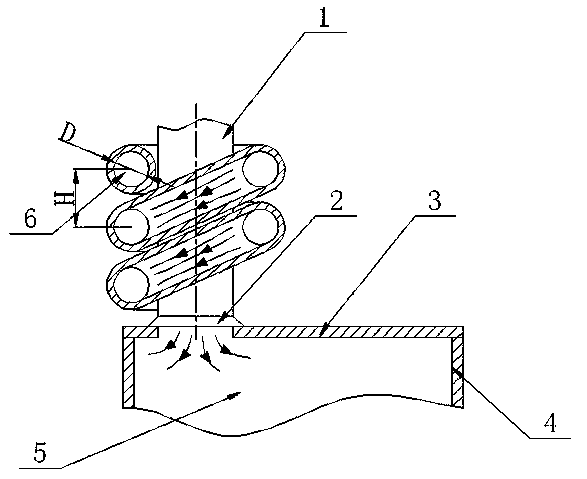

[0018] Figure 4 , 5 , 6 shows the structure diagram and cross-sectional view of the second type of spiral auxiliary inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com