Multi-screw type frequency conversion refrigeration compressor

A refrigeration compressor and multi-screw technology, which is applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of damage to internal components of the compressor, limited processing technology, poor reliability, etc., to prolong life and reduce Low cost and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

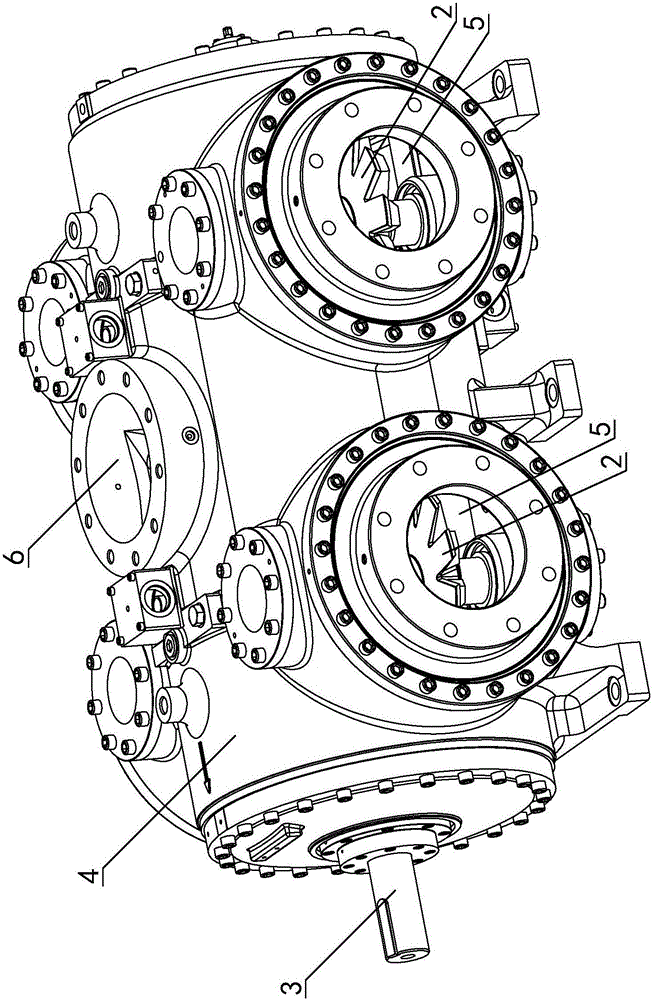

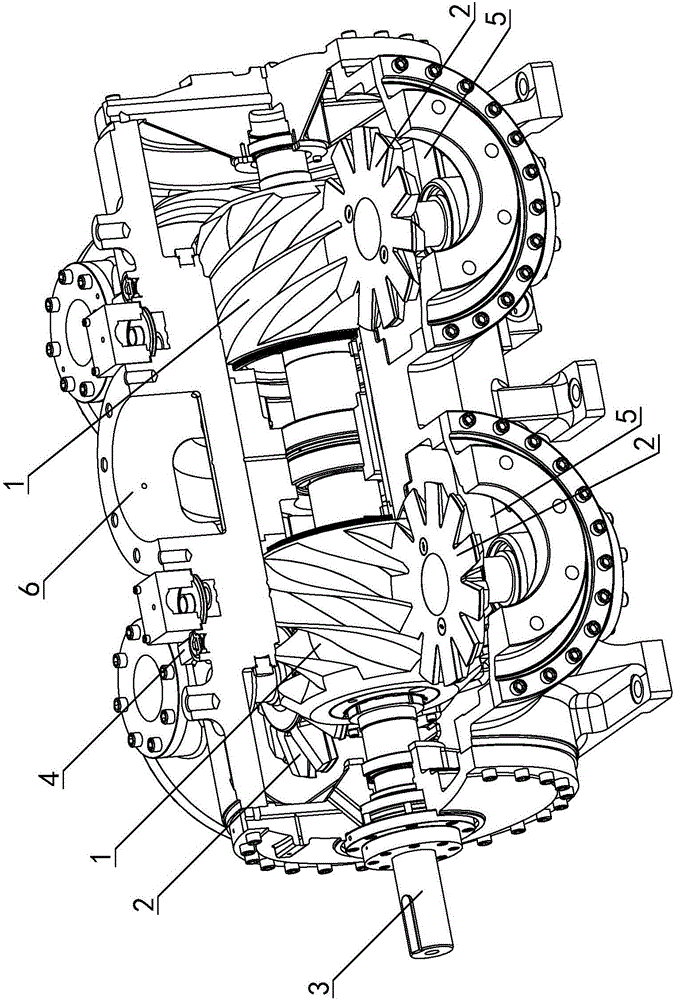

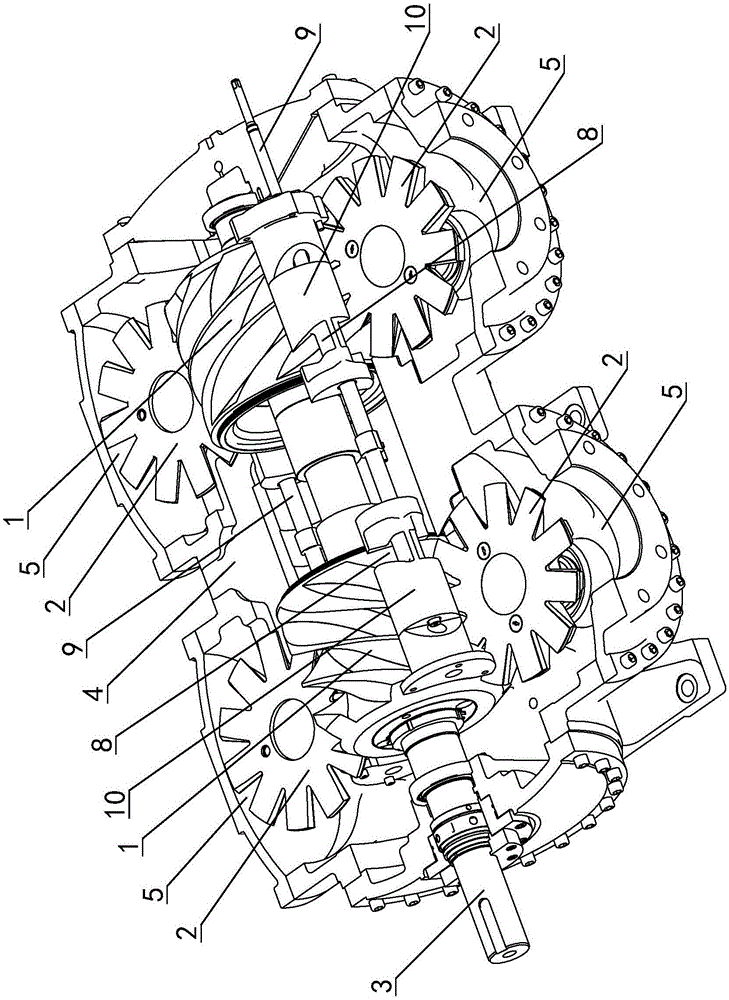

[0031] Example: see attached Figure 1~6As shown, a multi-screw variable frequency refrigeration compressor includes a casing, which includes a horizontally arranged motor side (not shown in the figure) and a compression side; the motor side is used to assemble a refrigeration compressor Frequency conversion motor, the motor includes a stator, a rotor and a motor main shaft; the compression side is used to assemble the screw rotor 1 and the star wheel 2 of the refrigeration compressor, and the star wheel 2 is arranged on both sides of the screw rotor 1 to form each screw rotor The rotor 1 is paired with two star wheels 2; the main shaft of the motor is connected to the shaft 3 of the screw rotor 1.

[0032] Wherein, there are two screw rotors 1, and each screw rotor 1 is set on the rotating shaft 3 along the length direction of the rotating shaft 3; the two screw rotors 1 are arranged oppositely with their high-pressure exhaust sides. With this design, the pressure on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com