Automatic limiting and looseness-resisting fastening assembly

A fastening component and automatic limit technology, which is applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problem of difficult fastening parts management, connecting bolts without limit, bolts, spring washers, flat washers Problems such as falling off, to achieve the effect of improving efficiency, easy management, and protecting equipment from collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

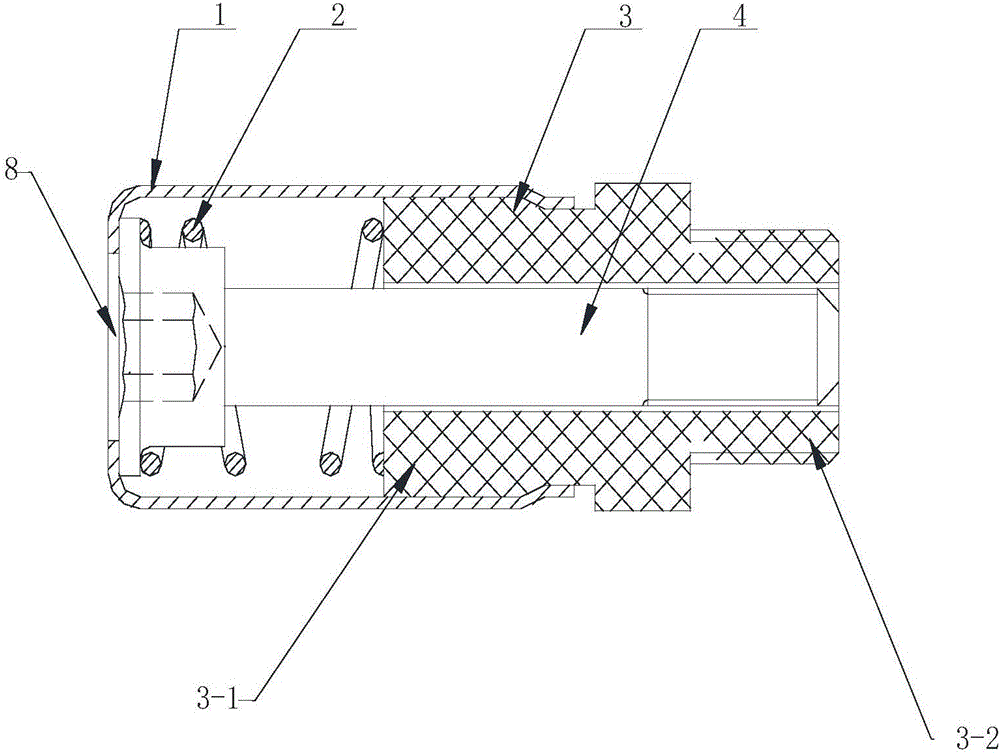

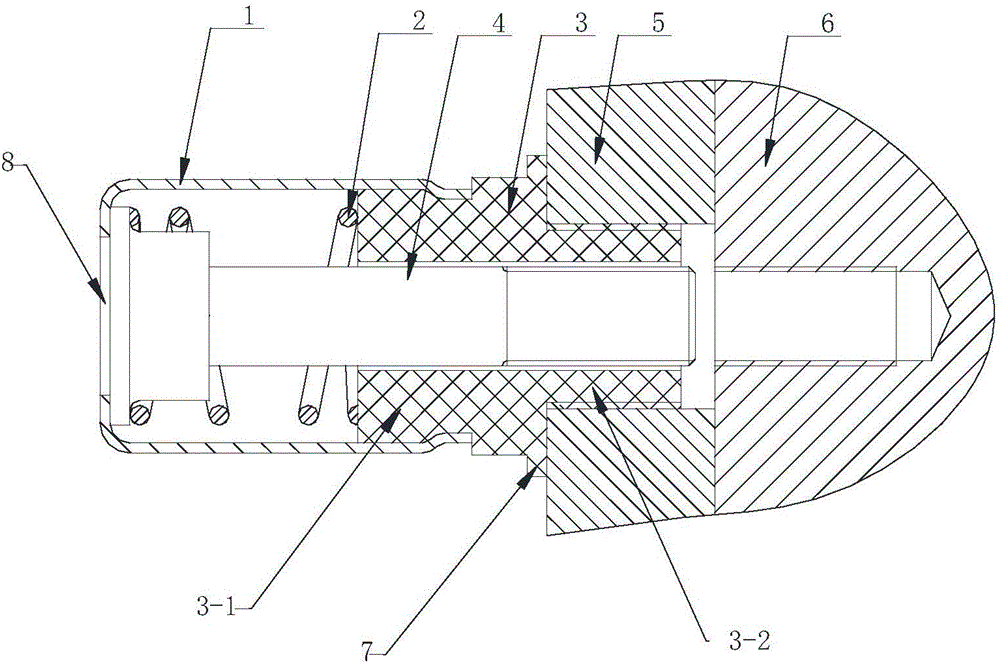

[0026] Such as Figure 1~3 As shown, it includes a limit sleeve 1, a positioning sleeve 3 and a bolt 4. The front portion of the limit sleeve 1 is open, and the rear portion is provided with a screwdriver jack 8. The positioning sleeve 3 is a hollow cylindrical structure, and the positioning sleeve 3 The front end is provided with a small-diameter insertion end 3-2, and the rear end is fixedly connected with the front part of the limit sleeve 1, forming a limit cavity in the limit sleeve 1, and the threaded end of the bolt 4 is inserted into the Installed in the positioning sleeve 3, the nut end is located in the limiting cavity, a spring 2 is arranged between the nut and the positioning sleeve 3; the diameter of the screwdriver hole 8 is smaller than that of the nut diameter of.

[0027] The rear end of the positioning sleeve 3 is provided with a connected step 3-1, and the positioning sleeve 1 is assembled on the step 3-1 of the positioning sleeve through a rolling process;...

Embodiment 2

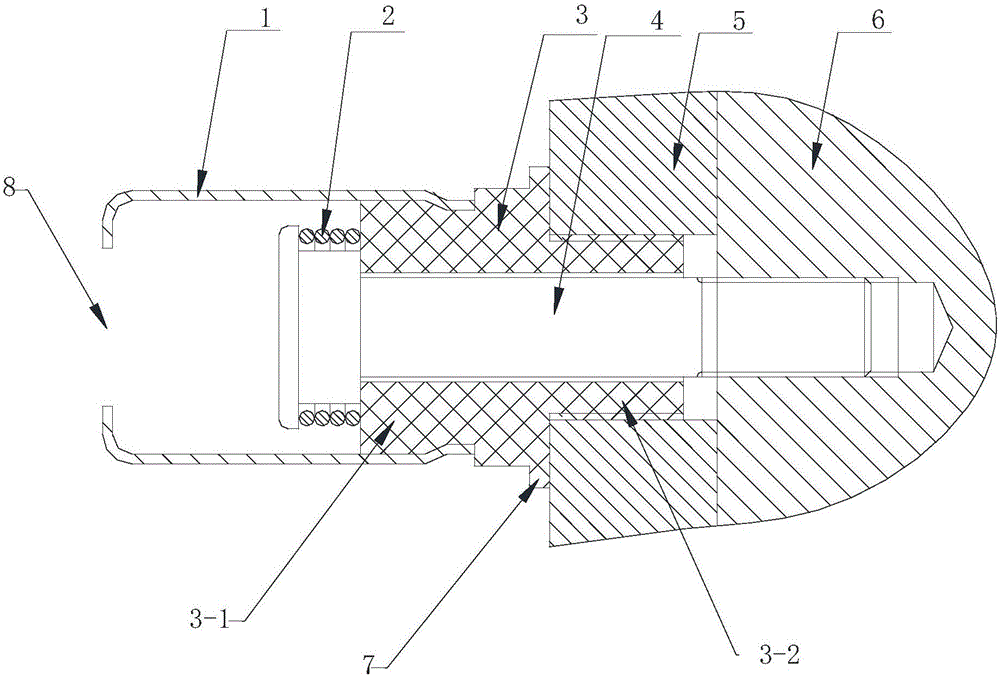

[0034] Such as Figure 4 As shown, it includes a limiting sleeve 1, a positioning sleeve 3 and a bolt 4 in an integrated structure. The positioning sleeve 3 is a hollow cylindrical structure. The front end of the positioning sleeve 3 is provided with a small-diameter insertion end 3-2, and the rear end It is integrally connected with the front part of the limit sleeve 1, and a limit cavity is formed in the limit sleeve 1. The rear part of the limit sleeve 1 is provided with a screwdriver socket, and the threaded end of the bolt is inserted into the In the positioning sleeve 3, the nut end is located in the limiting cavity, and a spring 2 is arranged between the nut and the positioning sleeve 3; the diameter of the screwdriver hole is smaller than the diameter of the nut .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com