Transverse oil-pressure shock absorber system for high-speed motor car

A technology of oil pressure shock absorber and shock absorber, which is applied in the direction of shock absorber, gas-hydraulic shock absorber, shock absorber, etc. It can solve the problems of oil emulsification and deterioration, shortening service life, etc., to ensure normal operation , to avoid the effect of emulsification and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

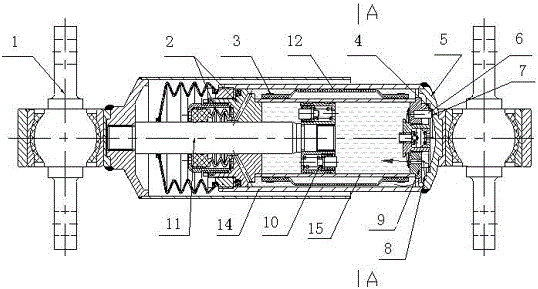

[0028] A transverse hydraulic shock absorber of the present invention, especially a transverse hydraulic shock absorber for a high-speed motor vehicle, will be further described in detail with reference to the accompanying drawings.

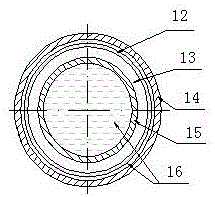

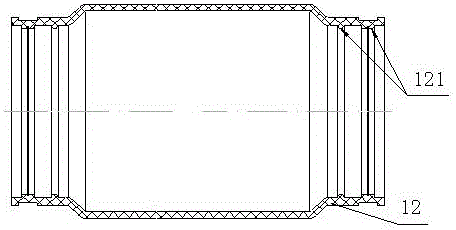

[0029] like figure 1 The schematic diagram of the structure of the lateral hydraulic shock absorber of the present invention is shown, including node 1, guide sealing device 2, cable tie 3, sealing ring 4, oil storage cylinder seat 5, positioning pin 6, positioning groove 7, oil supply channel 8 , Bottom valve assembly 9, piston assembly 10, piston rod assembly 11, air bag 12, oil storage cylinder 14, working cylinder 15.

[0030] The shock absorber body is arranged horizontally, nodes 1 are arranged at both ends of the shock absorber body, and an oil storage cylinder 14 and a working cylinder 15 are sequentially arranged on the shock absorber body from outside to inside, and the oil storage cylinder 14 and The left end of the working cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com