Centrifugal pendulum device with variable rotating radius

A rotation radius, centrifugal pendulum technology, applied in the direction of rotation vibration suppression, spring/shock absorber, vibration suppression adjustment, etc., can solve the problem that the shock absorber can not meet the requirements of vehicle comfort well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

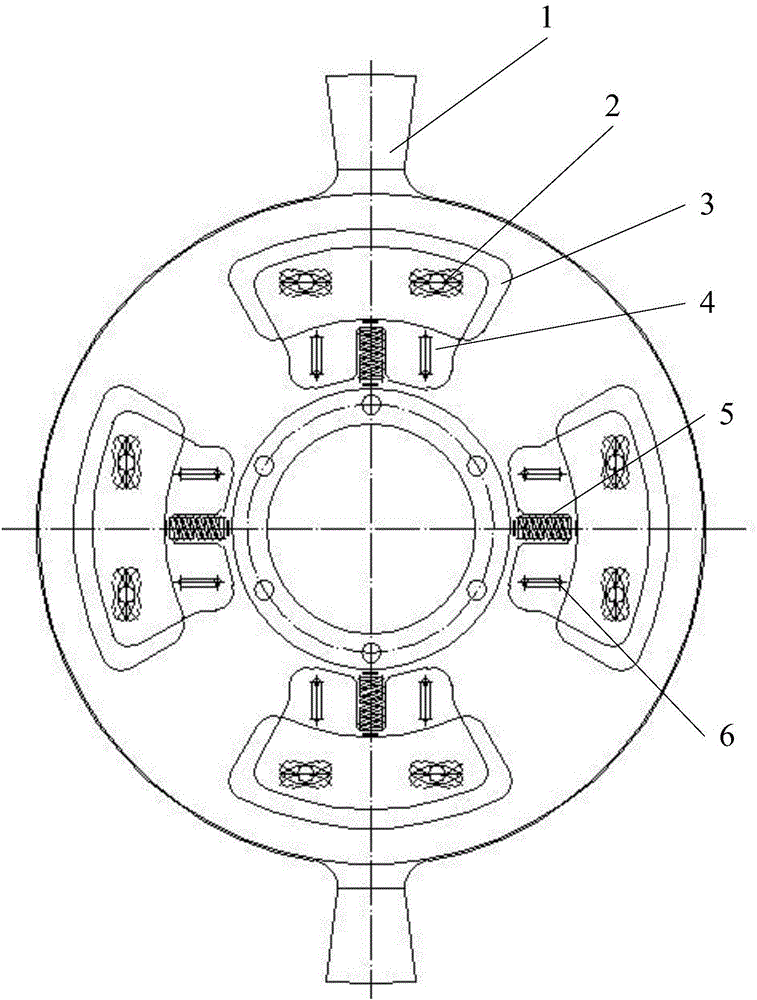

[0025] see figure 1 As shown, the centrifugal pendulum device with variable radius of rotation described in the embodiment of the present invention is mounted in the shock absorber of the vehicle, and includes a dial 1 and four groups of sliding pieces 4 symmetrically arranged on the dial, a return spring 5, Rivet 2, centrifugal pendulum 3 and limit rivet 6, slide plate 4 can be radially slidably assembled on dial 1 through limit rivet 6, and slide plate 4 and dial 1 are connected by return spring 5 at the same time; centrifugal pendulum 3 is swingably installed on the sliding piece 4 through the rivet 2.

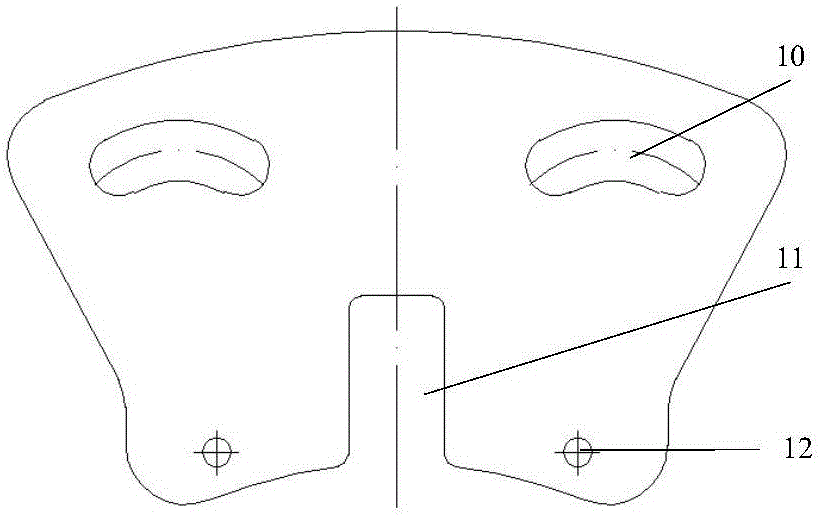

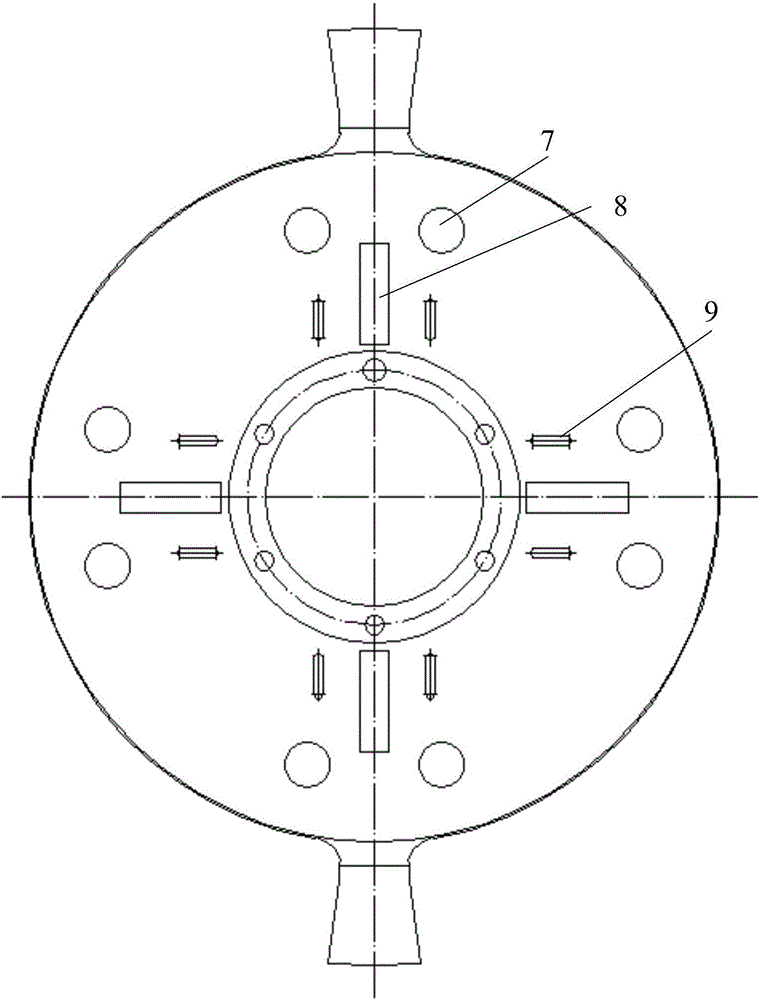

[0026] see Figure 2 ~ Figure 4 As shown, the dial 1 is provided with a dial rivet working hole 7, the centrifugal pendulum 3 is provided with a centrifugal pendulum arc groove 13, and the slider 4 is provided with a slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com