Different-quality heat recovery refrigerant undercooling and reheating air conditioner and air processing method thereof

A heat recovery and air conditioner technology, applied in heat recovery systems, control input related to air characteristics, heating methods, etc., can solve indoor cross-contamination, energy loss, no longer heat recovery, etc., to avoid cross-contamination and save energy High energy consumption and recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

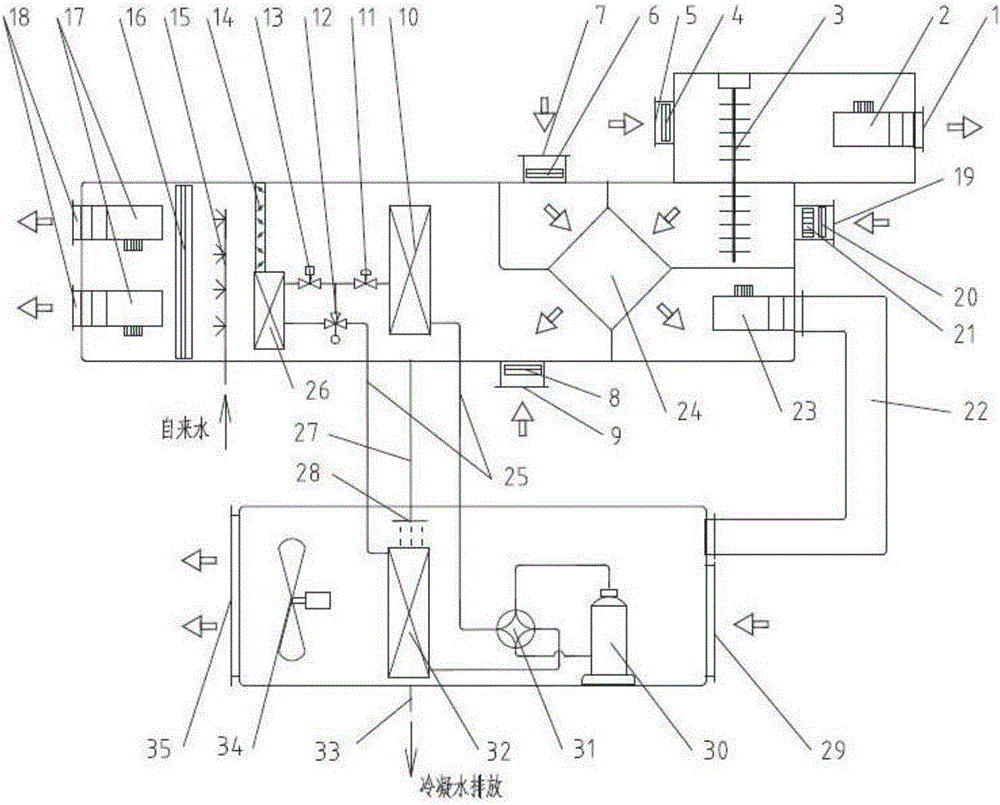

[0030] Such as figure 1 As shown, a kind of separated heat recovery refrigerant subcooling and reheating air conditioner provided by the present invention includes an indoor unit module, an outdoor unit module and a heat pump unit; the indoor unit module further includes an air supply channel, two Exhaust air channel and a clean air return channel, the air supply channel includes the fresh air channel in the front section and the mixed air channel of fresh air and return air in the rear section; wherein, the fresh air in the fresh air channel in the front section of the air supply channel is sequentially A fresh air primary effect filter 20, an electrostatic precipitator 21, a heat pipe heat exchanger 3, and a plate-fin type total hot air heat exchanger 24 are provided, and the fresh air primary effect filter 20 is connected to the fresh air inlet 19 of the indoor unit; the air supply channel The first indoor unit heat exchanger 10, the second indoor unit heat exchanger 26, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap