High-voltage hot-line work robot insulating hopper hydraulic air-conditioning system and method

A technology for working robots and air-conditioning systems, applied in air-conditioning systems, compressors with reversible cycles, compressors, etc., can solve the problems of fluctuating cooling effect, high fuel consumption, high cost of use, and black smoke, so as to avoid black smoke. Smoke phenomenon, reduce workload, increase stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in detail below in conjunction with accompanying drawing:

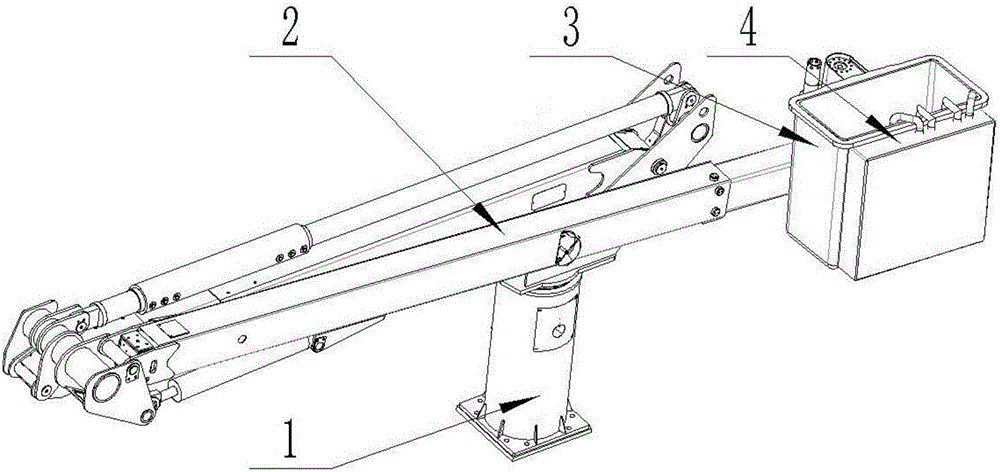

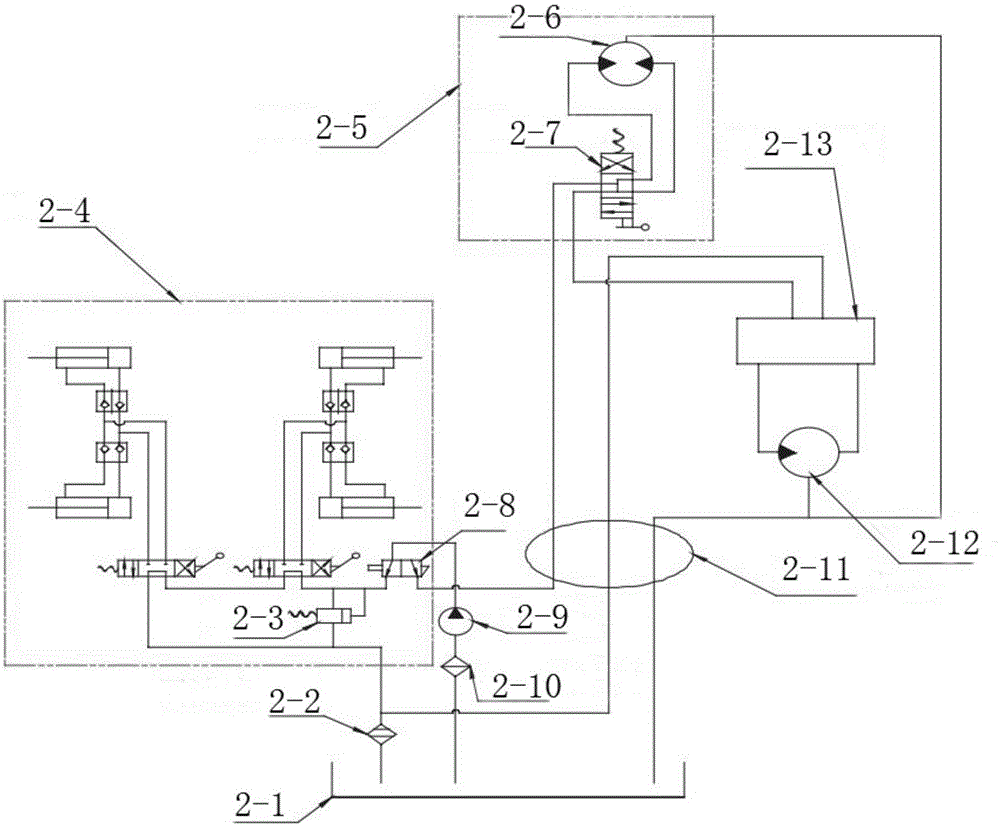

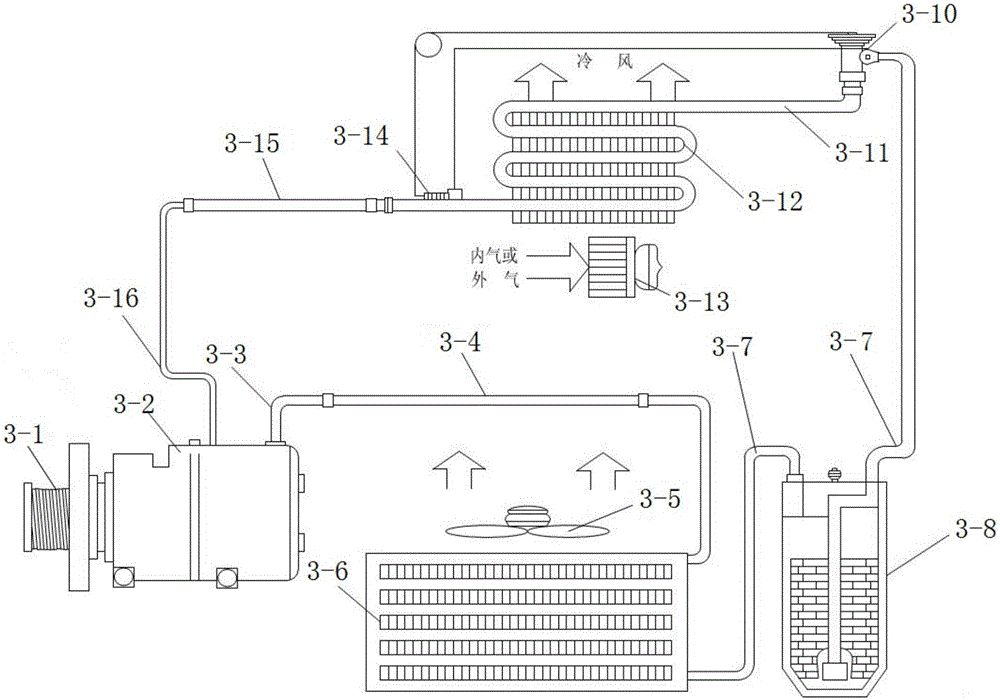

[0054]A hydraulic air-conditioning system for an insulated bucket of a high-voltage live working robot, comprising: a hydraulic system of an insulated bucket arm vehicle, an air-conditioning hydraulic motor 2-12, a transmission system, and an air-conditioning system; the air-conditioning hydraulic motor 2-12 and the oil tank 2 of the hydraulic system of the insulated bucket arm vehicle -1 connection, the air-conditioning hydraulic motor 2-12 is connected to the compressor 3-2 in the air-conditioning system through the transmission system; the air-conditioning system is set on the insulating bucket of the high-voltage live working robot;

[0055] The hydraulic oil in the hydraulic system of the insulated bucket arm truck enters the air-conditioning hydraulic motor 2-12, and the air-conditioning hydraulic motor 2-12 drives the compressor 3-2 in the air-conditioning system to work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com