Snow producing machine

A snow making and snowflake technology, applied in the field of artificial snowfall equipment, can solve the problems of high investment cost, complex structure, unsuitable for use in small ski resorts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

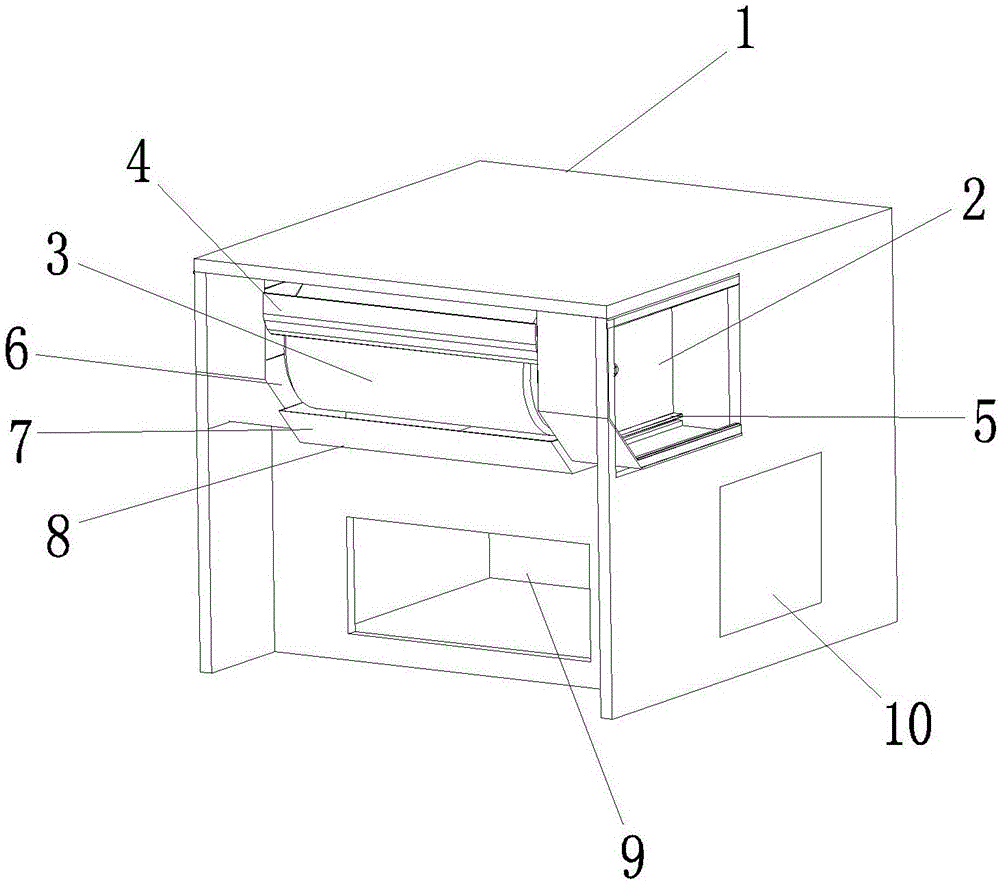

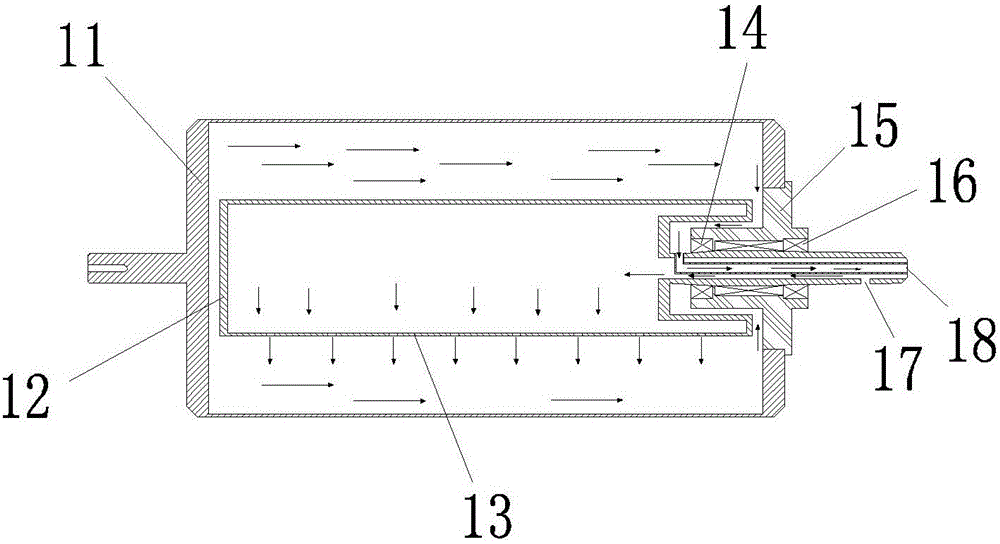

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a housing 1, which also includes a drum device 3, a swing air supply device 9, and a cutter 4; the inside of the housing 1 is divided into an upper cavity and a lower cavity; the upper cavity is horizontally provided with a drum device 3; The right end of the roller device 3 is connected with the transmission device 2;

[0019] The upper end of the drum device 3 is provided with a cutter 4, and the lower end is provided with a water tank 7; the drum device 3 is immersed in the water tank 7 and is in a gap connection with the water tank 7; Rotate to form layers of ice on the surface; when the ice layer reaches the set thickness, it contacts the cutter 4, and the thin ice cut into flakes by the cutter 4 falls down;

[0020] The bottom of the water tank 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com