Hydrogenation air cooling pipe bundle system for preventing ammonium salt flowing corrosion large leakage pipe blasting risk

A flow corrosion and large leakage technology, applied in lighting and heating equipment, heat exchange equipment safety devices, heat exchange equipment, etc., to improve the economic benefits of enterprises, reduce production and maintenance costs, and reduce the effect of crude oil inferiority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

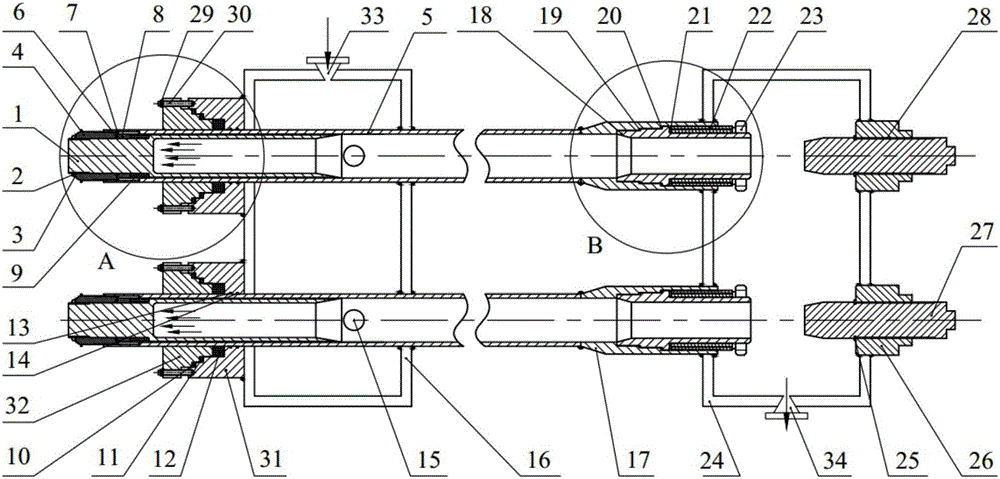

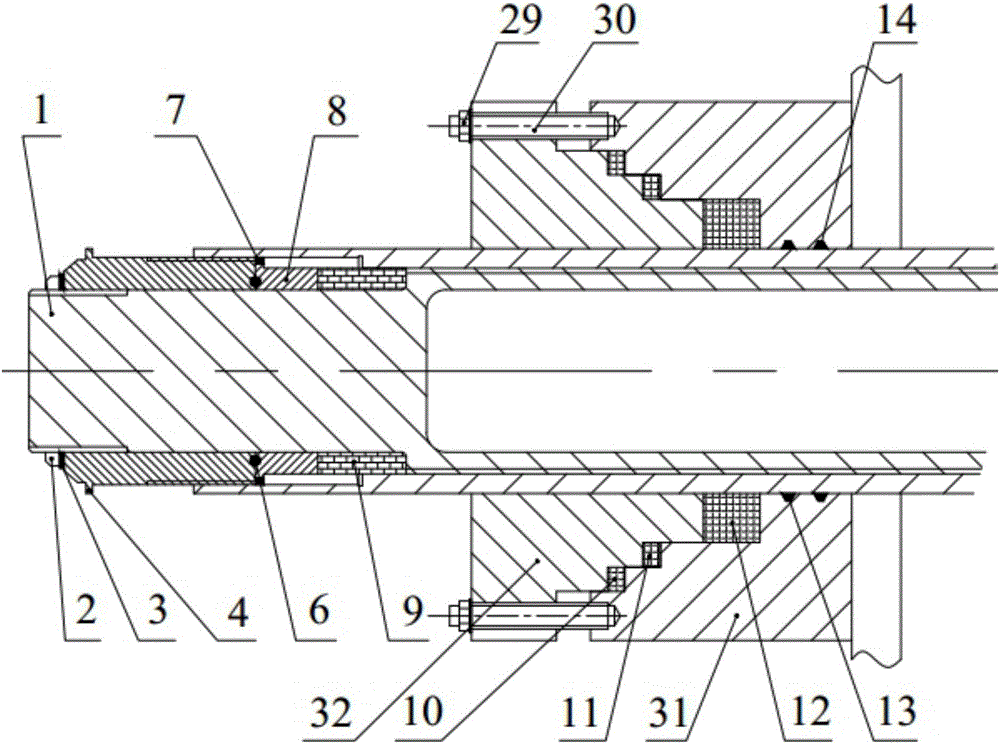

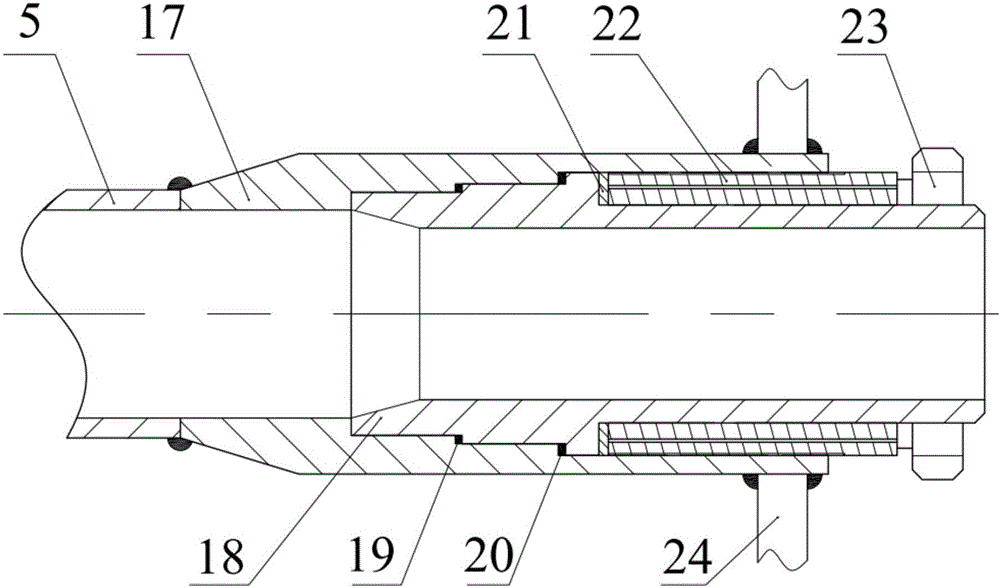

[0024] Such as figure 1 As shown, the present invention comprises inlet pipe box 16, outlet pipe box 24, tube bundle 5, thick-walled pipe 17, telescoping pipe section 1, pressure sensor 21 and threaded compression member 22; inlet pipe box 16 and outlet pipe box 24 are arranged in parallel and The cross-section is rectangular, and the inlet pipe box 16 and the outlet pipe box 24 are connected by upper and lower rows of horizontally parallel tube bundles 5; wherein, the inlet pipe box 16 is arranged with upper and lower rows of horizontally parallel tube bundles 5, each Both ends of the tube bundle 5 pass through the inlet tube box 16, that is, the two ends of the tube bundle 5 pass through the two sides of the rectangular tube box respectively, and the interference fit between the tube bundle 5 and the through holes of the box plates on both sides of the inlet tube box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com