High-temperature and high-pressure centrifuging pump impeller comprehensive design method based on multidisciplinary optimization

A centrifugal pump impeller, high temperature and high pressure technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as backward theory, neglect of engineering system interrelations, inability to meet the needs of engineering technology development, etc., to achieve safety Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

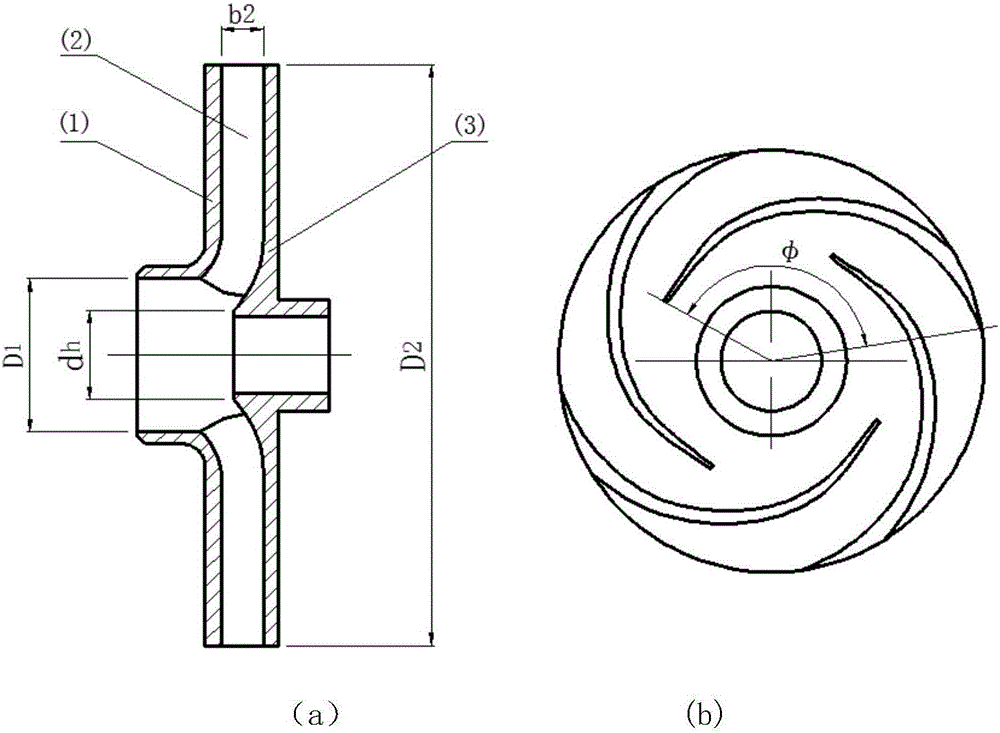

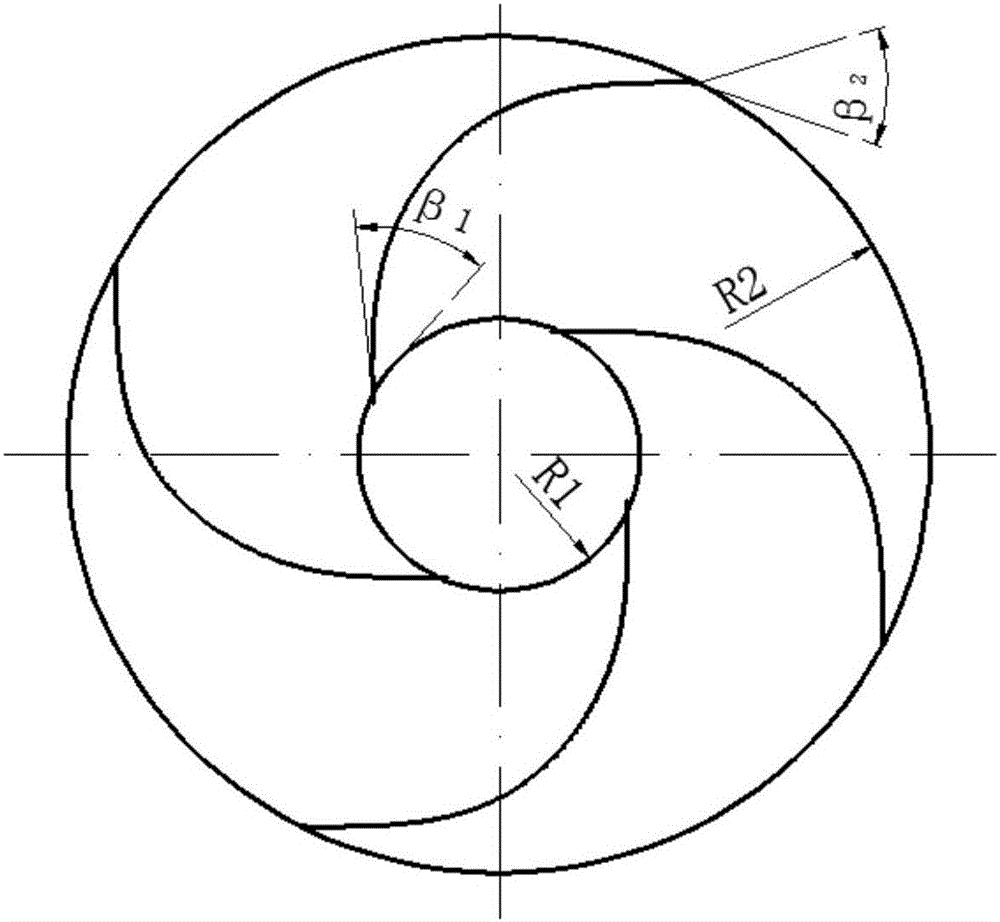

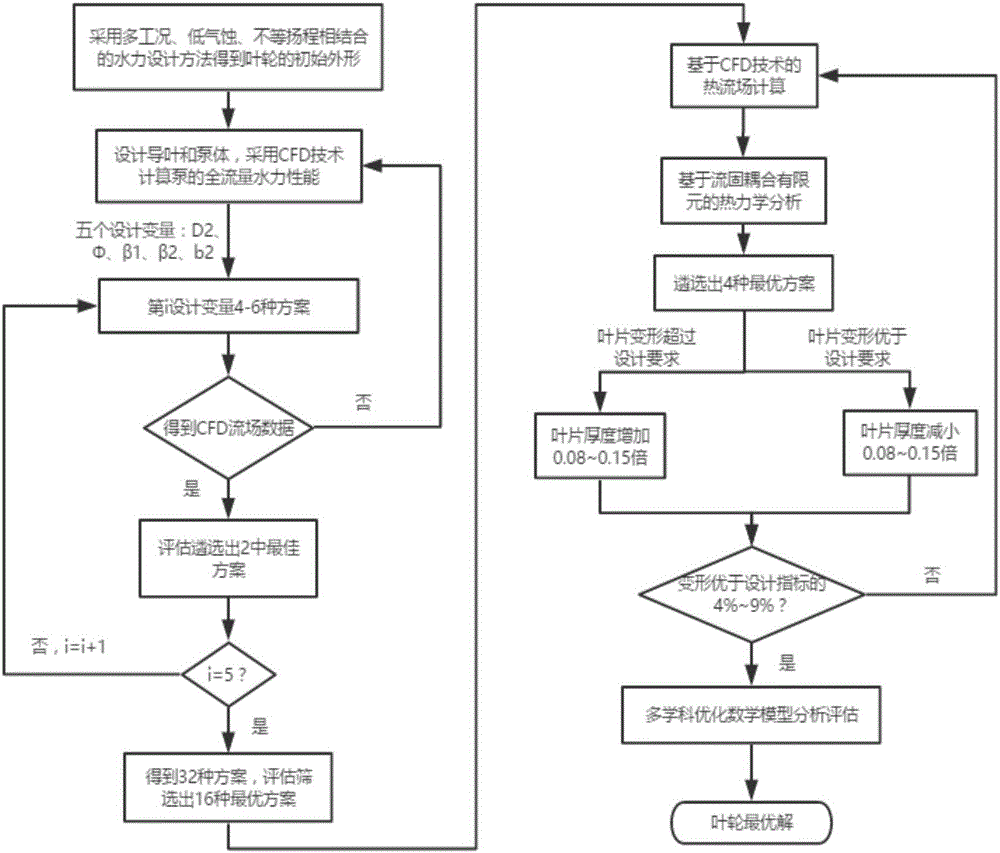

[0042] figure 1 and figure 2 It is a sketch of the impeller and its geometric parameter representation of an embodiment of the present invention, image 3It is a flow chart of the multidisciplinary optimization design of the present invention. The optimization design process is divided into system-level optimization and subsystem-level optimization. The task of system-level optimization is to achieve multiple working conditions, low cavitation, and high efficiency of centrifugal pumps under high temperature and high pressure conditions. The advanced hydraulic design method optimizes the target performance of multiple systems; subsystem-level optimization includes hydraulic optimization based on CFD technology, reliability optimization based on structural mechanics, multi-field coupling design based on thermodynamics, and analysis of the coordination generated by the interaction of various disciplines Effects to obtain the overall optimal solution of the system, including the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com